A kind of solar greenhouse wall body and preparation method thereof

A solar greenhouse and wall technology, which is applied to botanical equipment and methods, greenhouse cultivation, walls, etc., can solve the problems of long construction period, easy to be damaged by external force, high cost, and achieve the effect of saving cost and time, and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

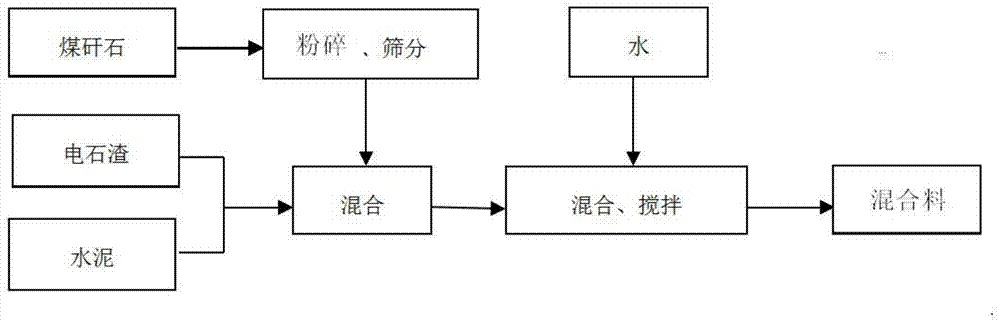

[0057] Process flow for manufacturing wall mixture mainly made of clay rock gangue in Ordos, Inner Mongolia (such as figure 1 ):

[0058] 1) After the coal gangue is crushed by a pulverizer, it is passed through a sieve with a sieve size of 4.75 mm and 9.5 mm, and the coal gangue with a particle size greater than 4.75 mm and less than 9.5 mm is used as coarse aggregate, and the coal gangue with a particle size less than 4.75 mm is used as coarse aggregate. Coal gangue is used as fine aggregate.

[0059] Measure respectively by the mixing ratio of the present embodiment:

[0060]

[0061] The balance is water.

[0062] 2) Pour the measured coal gangue coarse and fine material, calcium carbide slag and composite Portland cement with a strength grade of 32.5MPa into the mixing bin of the mixer, and start the machine. After stirring for 100s, add water slowly, finish adding in 35s, start stirring the machine for 250s and stop. Inner Mongolia Ordos clay rock coal gangue is ...

Embodiment 2

[0070] Process flow for manufacturing wall mixture mainly made of clay rock gangue in Ordos, Inner Mongolia (such as figure 1 )middle,

[0071] Step 1) in the present embodiment, the proportioning measurement is:

[0072]

[0073] The balance is water.

[0074] Preparation steps 2) to 5) are the same as in Example 1.

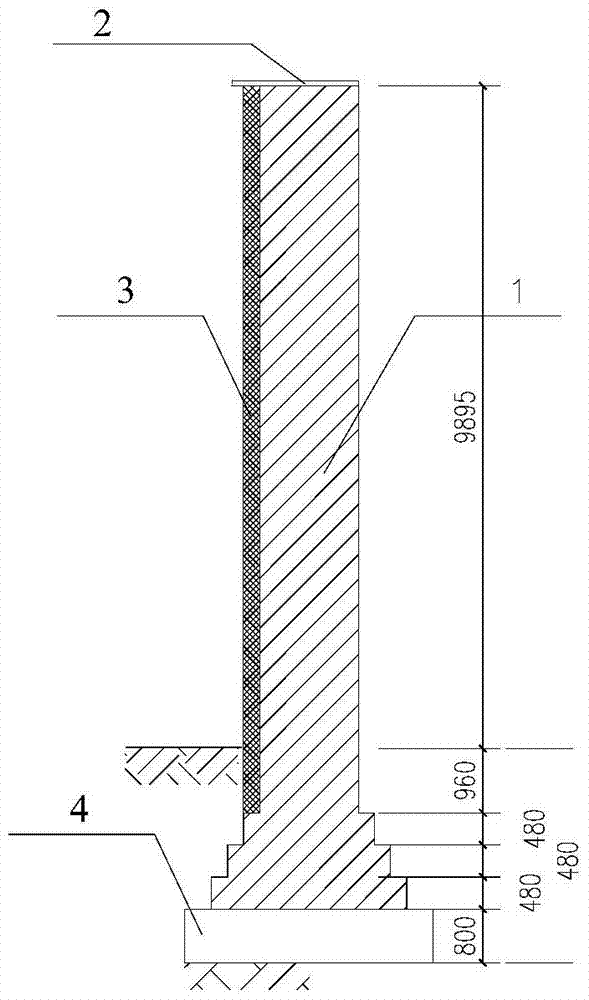

[0075] The apparent density of the prepared wall is about 2050kg / m 3 . The wall 1 is 1.7m deep into the ground, and the bottom is a concrete cushion 4. The concrete cushion is 220mm thick, and the two sides are 150mm wider than the wall; the top of the wall is 1580mm wide, and the bottom of the wall is 1800mm wide; The insulation polystyrene board 3 is 1050mm away from the inside of the wall; the thickness of the concrete C10 top layer 2 is 200mm, and the thickness of the concrete C10 moisture-proof layer 5 is 150mm. The top layer 2 is provided with a polystyrene insulation board to act as a cold bridge, and the distance between the polystyrene insulati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com