Inkjet printing method, inkjet printing device, and inkjet printing apparatus

A technology of inkjet printing and printers, applied in the direction of digital output to printing units, printing, instruments, etc., to achieve quality and quality assurance, and to solve the effect of overlapping or blank intervals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

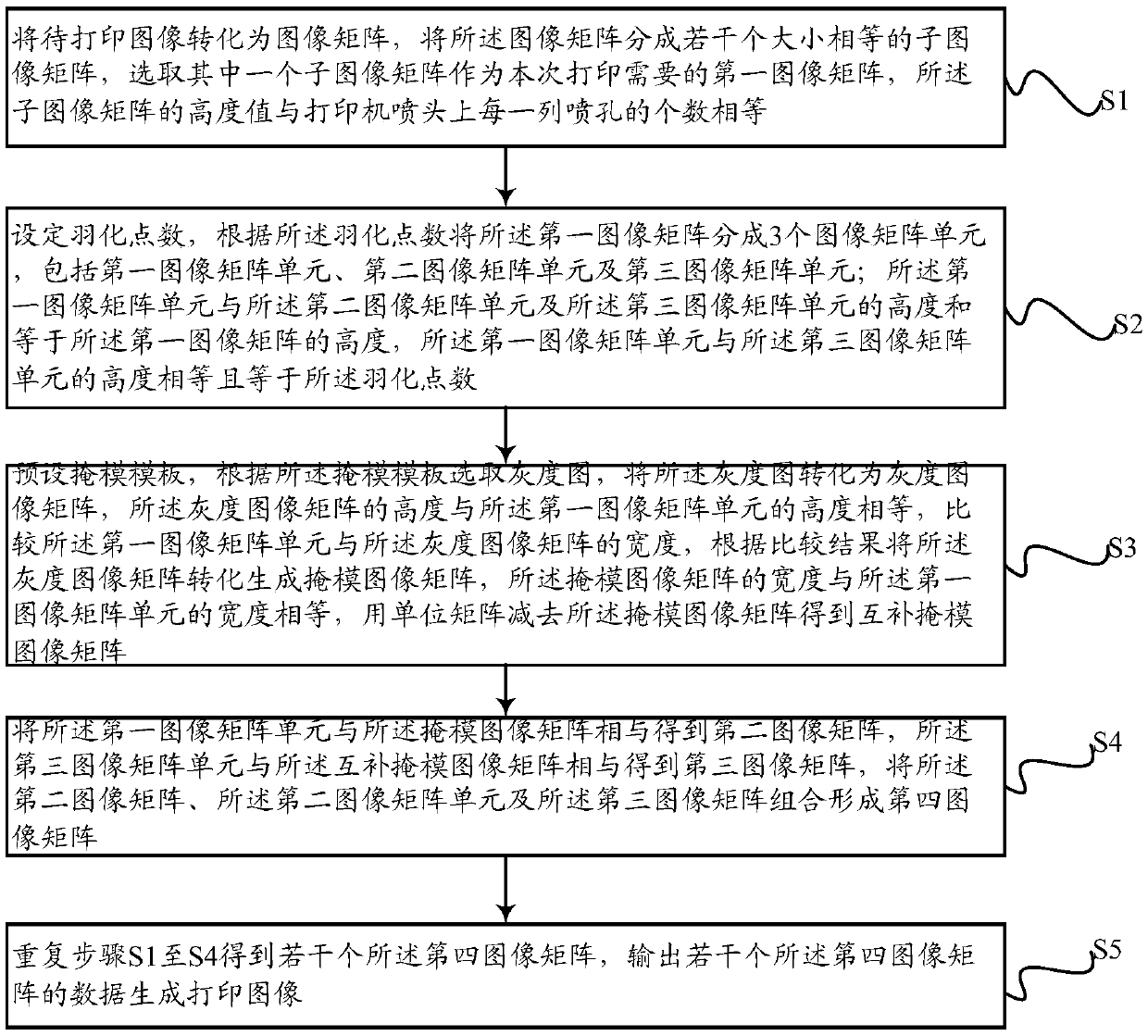

[0054] see figure 2 , the invention provides an inkjet printing method, comprising the steps of:

[0055] S1. Convert the image to be printed into an image matrix, divide the image matrix into several sub-image matrices of equal size, select one of the sub-image matrices as the first image matrix required for this printing, and the height of the sub-image matrix The value is equal to the number of each group of nozzle holes on the printer nozzle; in this embodiment, each group of nozzle holes on the printer nozzle includes several rows of nozzle holes, and several rows of nozzle holes are arranged in a staggered manner. The printed image is obtained by processing the halftone algorithm. The halftone algorithm is a common technology in the printing field. The halftone algorithm processing here can be implemented by methods in the prior art. The width of the first image matrix is equal to the width of the image matrix, assuming that the image matrix is C xy , the first im...

Embodiment 2

[0094] see Figure 14 , the present invention also provides an inkjet printing device, comprising:

[0095] The image matrix generation module 1 is used to convert the image to be printed into an image matrix, divide the image matrix into several sub-image matrices of equal size, and select one of the sub-image matrices as the first image matrix required for this printing, so The height value of the sub-image matrix is equal to the number of each group of nozzle holes on the printer nozzle.

[0096] Image matrix transformation module 2, used to set the number of feathering points, divide the first image matrix into 3 image matrix units according to the number of feathering points, including the first image matrix unit, the second image matrix unit and the third image matrix unit ; The height sum of the first image matrix unit, the second image matrix unit and the third image matrix unit is equal to the height of the first image matrix, and the first image matrix unit and th...

Embodiment 3

[0120] The present invention also provides an inkjet printing device, comprising: a memory, a processor, and a computer program stored on the memory and operable on the processor, when the computer program is executed by the processor, the following step:

[0121] S1. Convert the image to be printed into an image matrix, divide the image matrix into several sub-image matrices of equal size, select one of the sub-image matrices as the first image matrix required for this printing, and the height of the sub-image matrix The value is equal to the number of each group of orifices on the printer nozzle.

[0122] S2. Set the number of feathering points, divide the first image matrix into 3 image matrix units according to the number of feathering points, including the first image matrix unit, the second image matrix unit and the third image matrix unit; the first image The height sum of the matrix unit, the second image matrix unit and the third image matrix unit is equal to the hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com