Full-automatic wire-mounted binding machine and wire binding method

A fully automatic, binding machine technology, applied in binding and other directions, can solve problems such as troublesome binding, unstable threading process, low binding efficiency, etc., to achieve fast binding speed, stable and reliable threading process and knotting process, and high binding efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

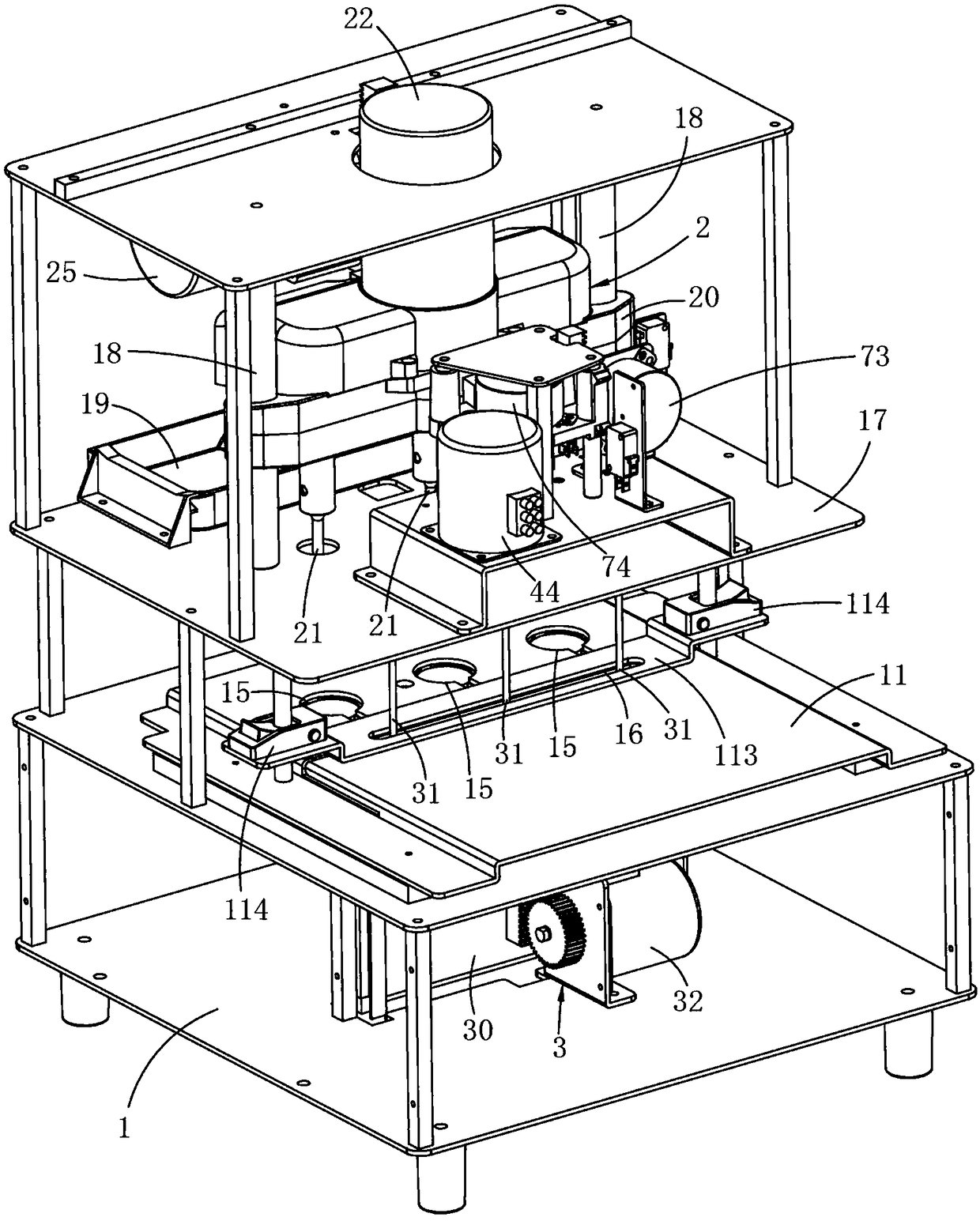

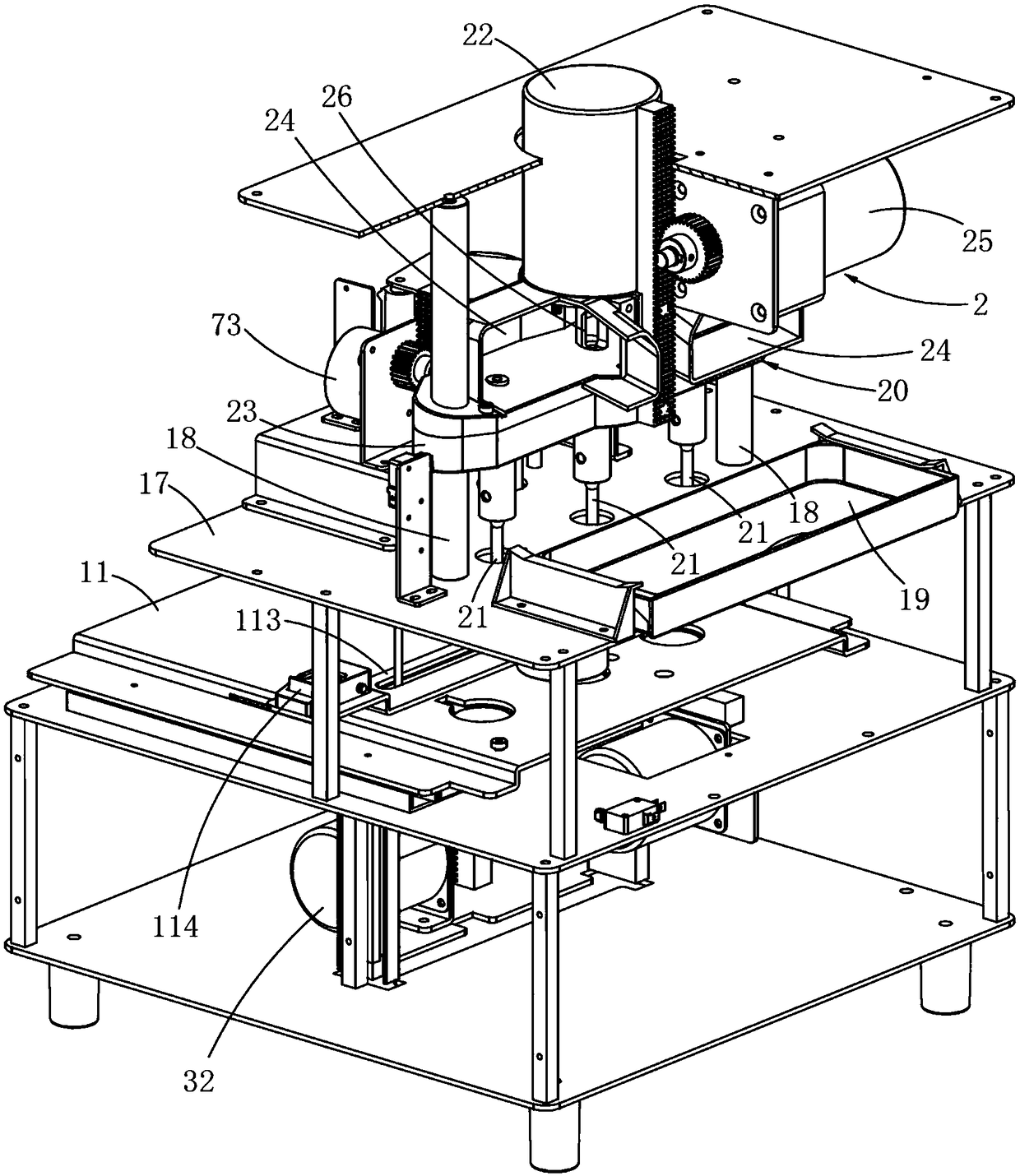

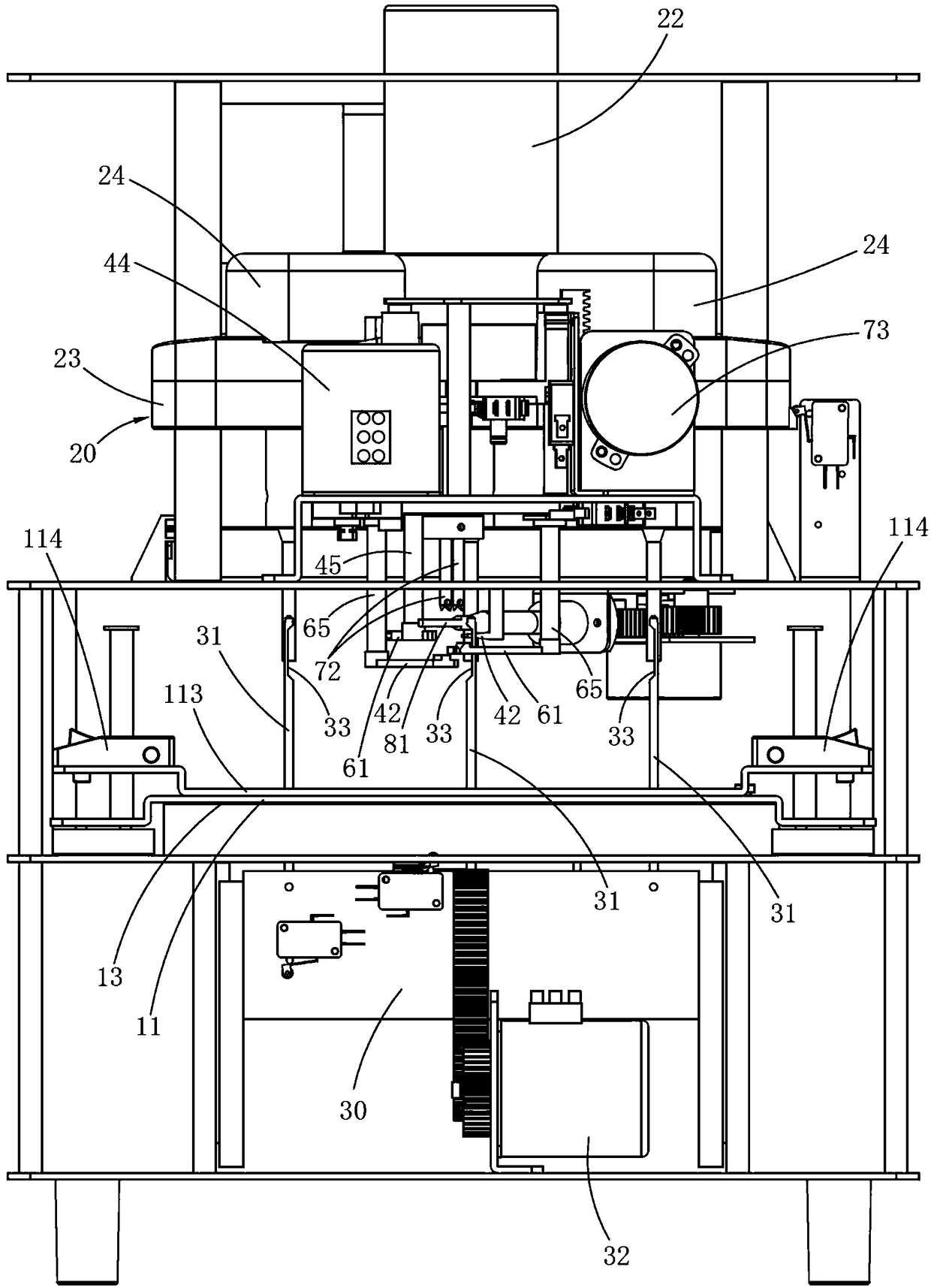

[0041] A fully automatic thread-bound binding machine, Figures 1 to 15 As shown, including a frame 1, a bottom plate 13 is fixed in the middle of the frame 1, and a binding platform 11 is slidably installed in the middle of the frame 1 for placing documents to be bound. Specifically, a platform driving motor 110 is fixed on the bottom plate 13, The bottom surface of the binding platform 11 is fixed with a platform driving rack 111 , and the platform driving motor 110 is connected to the platform driving rack 111 to drive the binding platform 11 to slide back and forth.

[0042] The left and right sides of the binding platform 11 are respectively fixed with a paper-pressing guide column 112, and the top of the binding platform 11 is provided with a paper-pressing plate 113, and the left and right sides of the paper-pressing plate 113 are slidably installed on the paper-pressing guide column 112 of the left and right sides respectively, and the paper-pressing plate Both sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com