Light-emitting diode assembly and manufacturing method thereof

A technology of light-emitting diodes and components, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices of light-emitting elements, light sources, etc., and can solve the problems of time-consuming manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

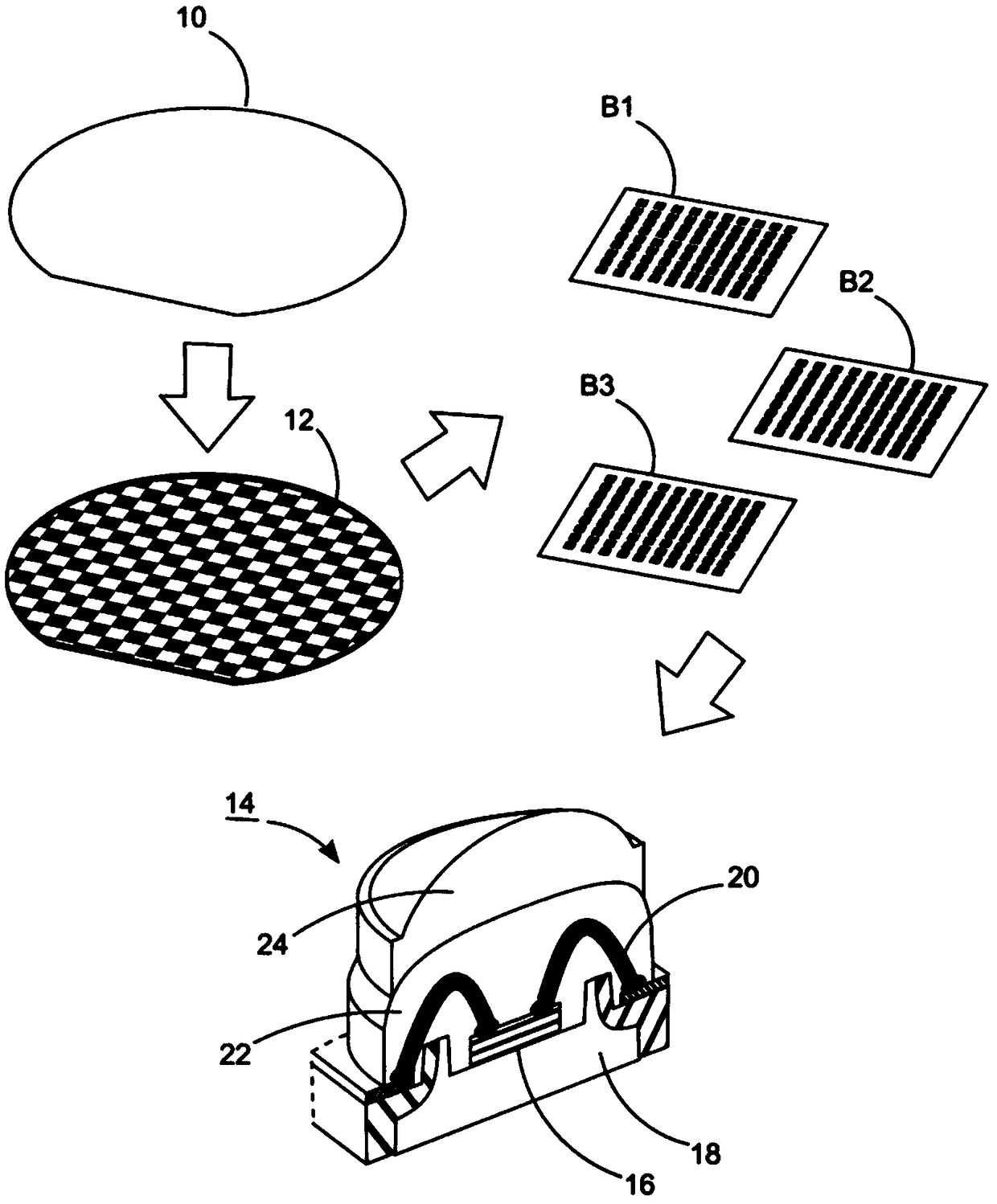

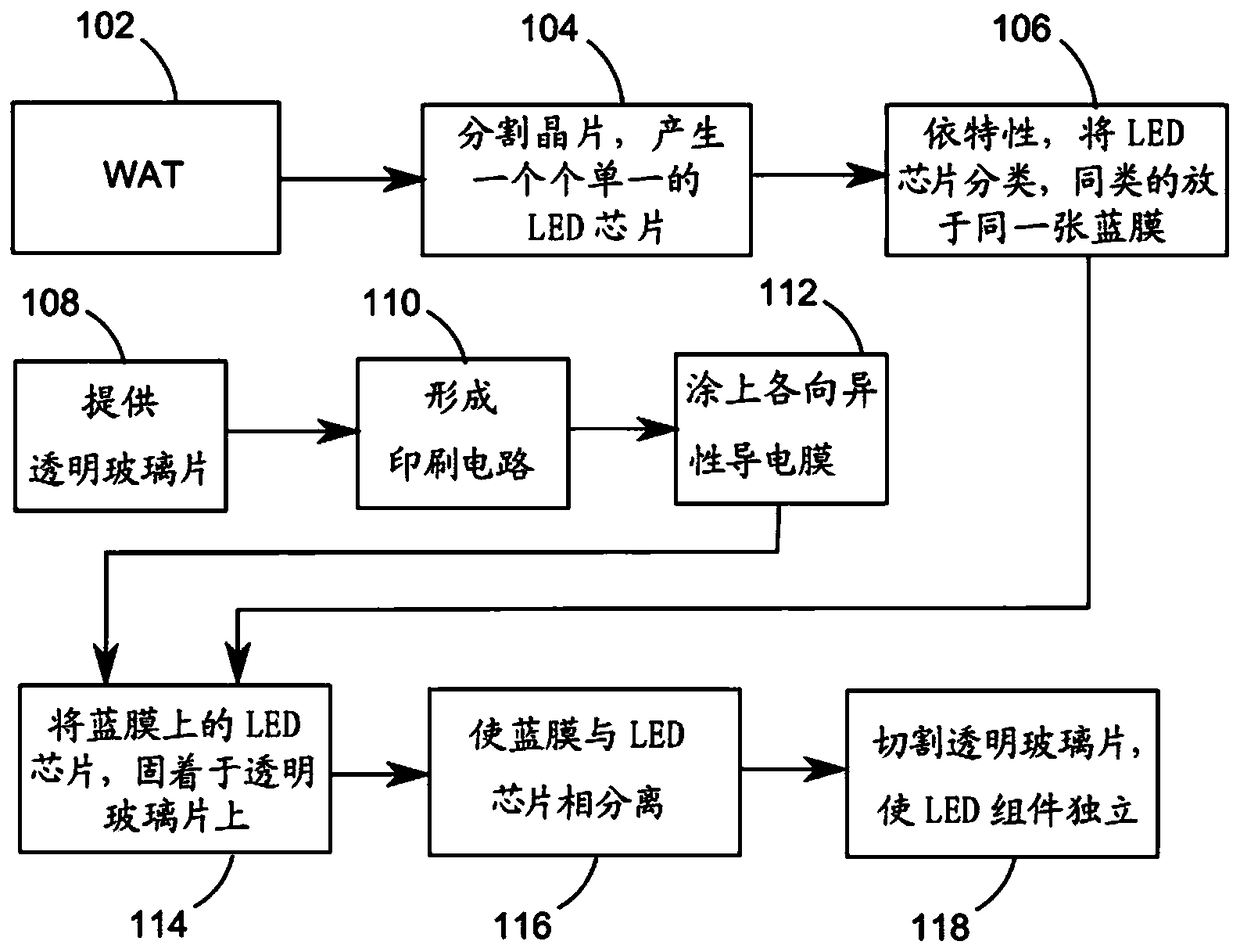

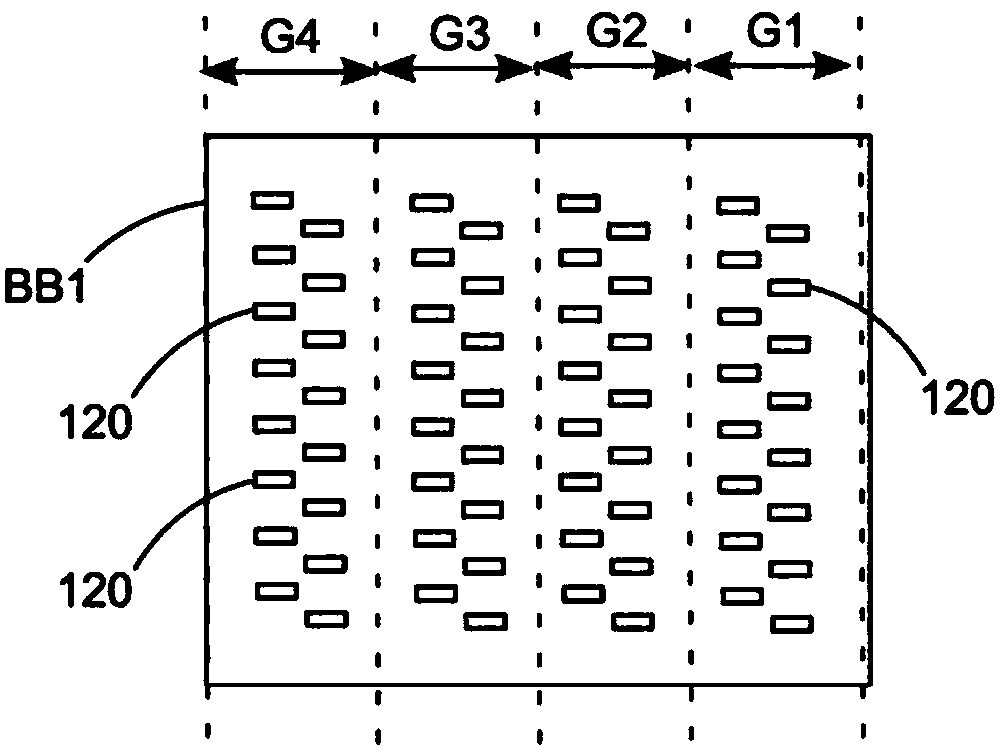

[0041] figure 2 It is a method for manufacturing an LED component according to the present invention. Step 102 performs a wafer acceptance test (WAT) on the wafer 12 with chips to determine whether it meets the specification. Step 104 cuts the qualified wafer 12 to separate individual LED chips. Step 106 detects each LED chip and classifies it according to its photoelectric characteristics, such as forward voltage, dominant wavelength, luminous intensity, etc., and classifies LED chips of the same type Placed on a temporary carrier film, the temporary carrier film can be blue tape. image 3 A temporary carrier film BB1 implemented according to the present invention is shown, on which LED chips 120 belonging to the same category are adhered. According to the positions, the LED chips 120 of the temporary carrier film BB1 can be roughly divided into four groups G1, G2, G3, and G4. The positions of all LED chips 120 in each group form a pattern, and the patterns of each group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com