A variable pitch electronic component mass transfer device and method

A technology of electronic components and transfer devices, applied in the direction of electrical components, electrical components, electrical solid devices, etc., which can solve the problems of inability to ensure the yield rate of self-assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

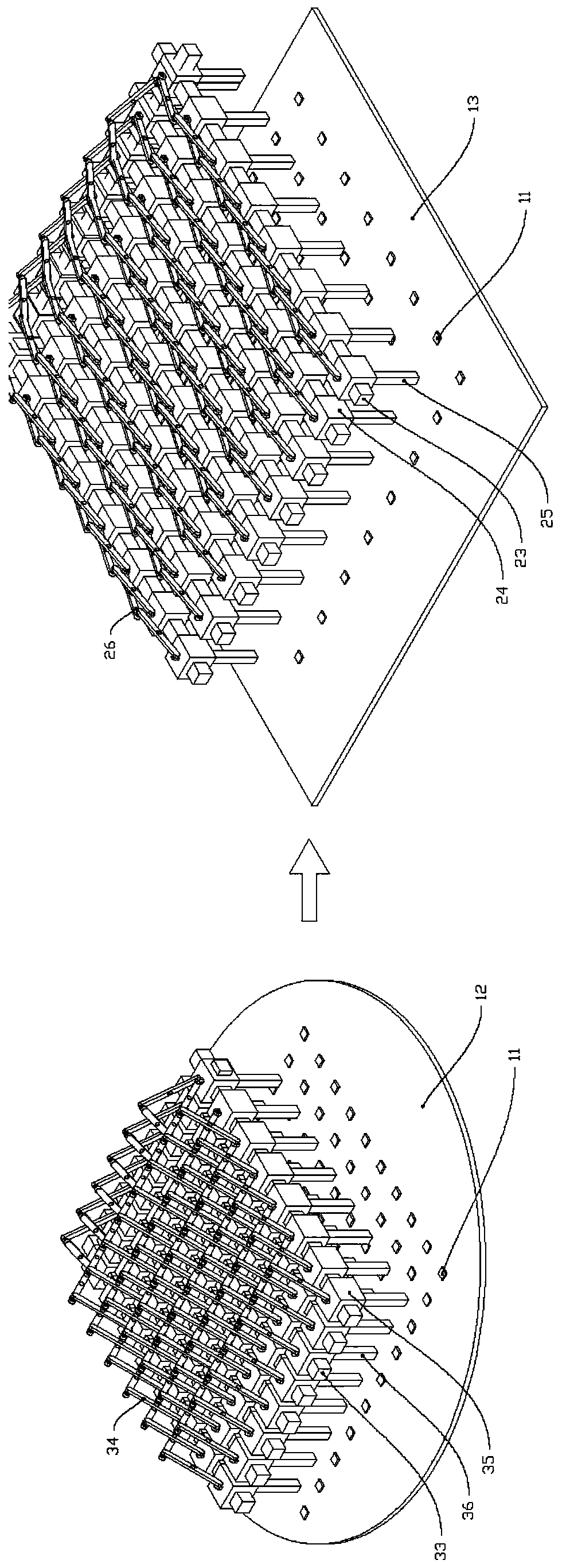

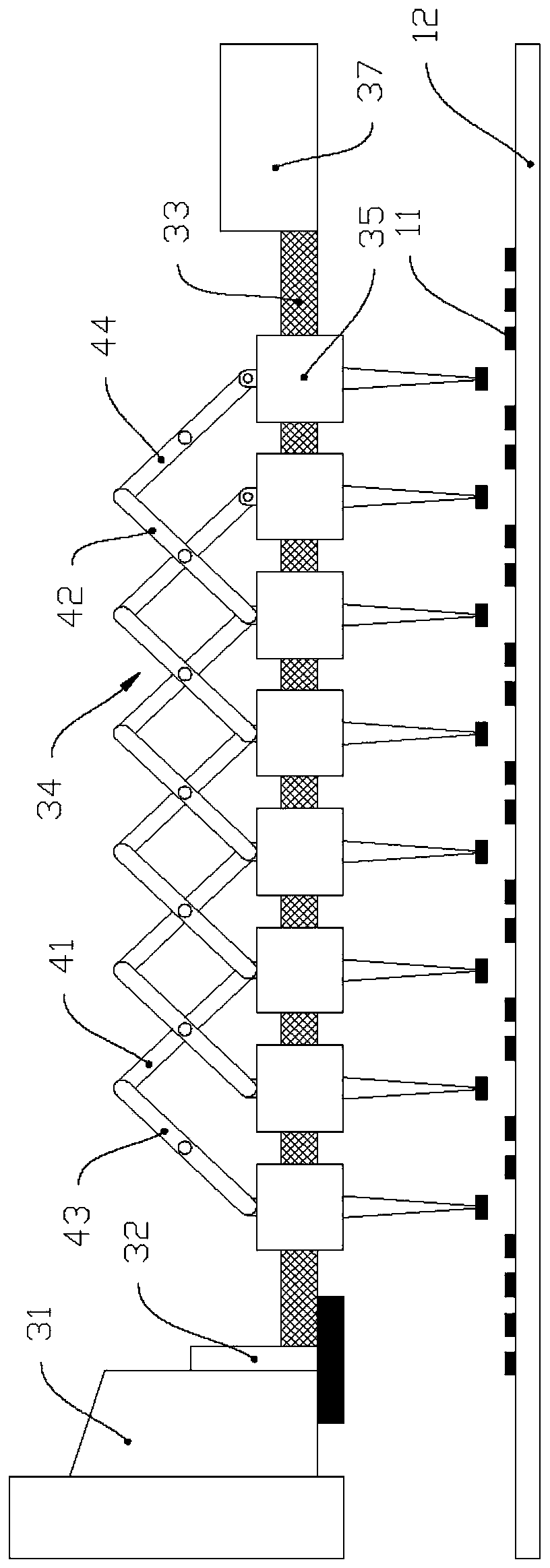

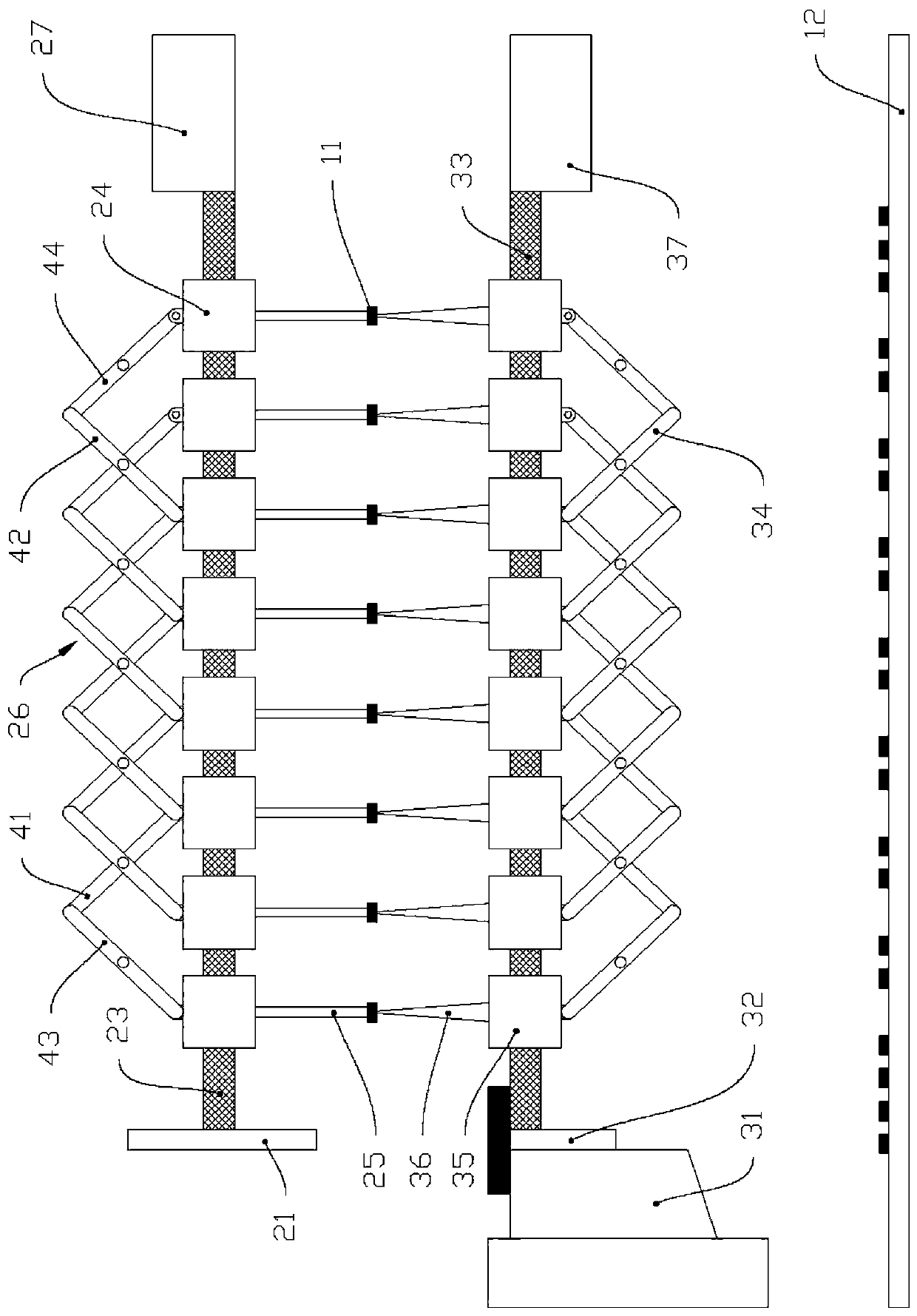

[0034] A mass transfer device for electronic components with variable pitch in this embodiment, such as Figure 2-4 As shown, including die bonding arm, die bonding drive motion platform, flip chip soldering arm, flip chip drive motion platform and operation table;

[0035] There are a plurality of said die-bonding arms, each of which includes a die-bonding guide rail 23, a die-bonding bracket 24, a crystal-bonding transfer head 25, a crystal-bonding connecting rod 26, and a crystal-bonding linear motor 27. There are a plurality of crystal-bonding brackets 24, and a plurality of the crystal-bonding brackets 24 are slidably connected with the described crystal-bonding guide rails 23, and each of the crystal-bonding brackets 24 is provided with a crystal-bonding transfer head 25 below. The crystal-bon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com