Method for producing air spinning multi-component 20-count yarn

A production method, multi-component technology, applied in the direction of yarn, textile and paper making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

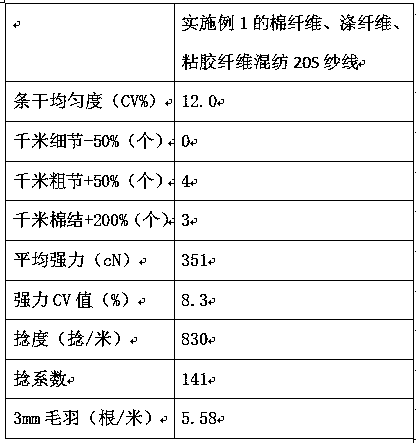

[0034] Example 1 A production method of air-spun multi-component yarn with 20 counts

[0035] Step 1. Raw material selection

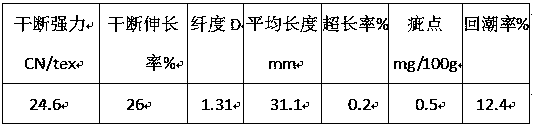

[0036] (1) Selected viscose fiber raw materials: dry breaking strength 24.6CN / tex, dry breaking elongation 26%, denier 1.31D, average length 31.1mm, overlength 0.2%, defect 0.5mg / 100g, moisture regain 12.4 %. The details are shown in the following table:

[0037]

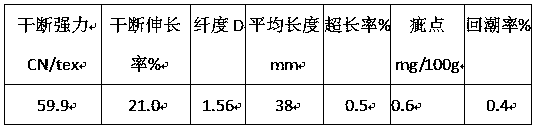

[0038] (2) Polyester fiber raw material selected: functional polyester fiber, dry breaking strength 59.9CN / tex, dry breaking elongation 21.0%, denier 1.56D, average length 38mm, overlength 0.5%, defect 0.6mg / 100g , Moisture regain 0.4%. The details are shown in the following table:

[0039]

[0040] (3) Selected cotton fiber raw materials: grade 329, micronaire value 4.22, uniformity 83.1%, upper half average 28.9mm, short fibers (length fibers below 16.5mm) accounted for 17.6%, strength 29 grams / tex , spinning stability parameter 135. The details are shown in the following table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com