Tunnel boost escape pipeline for long distance horizontal surface

An escape pipeline and horizontal plane technology, applied in safety devices, mining equipment, earthwork drilling, etc., can solve problems affecting escape timing, danger, human fatigue, etc., so as to reduce the probability of injury, improve the probability of escape, and improve the escape speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

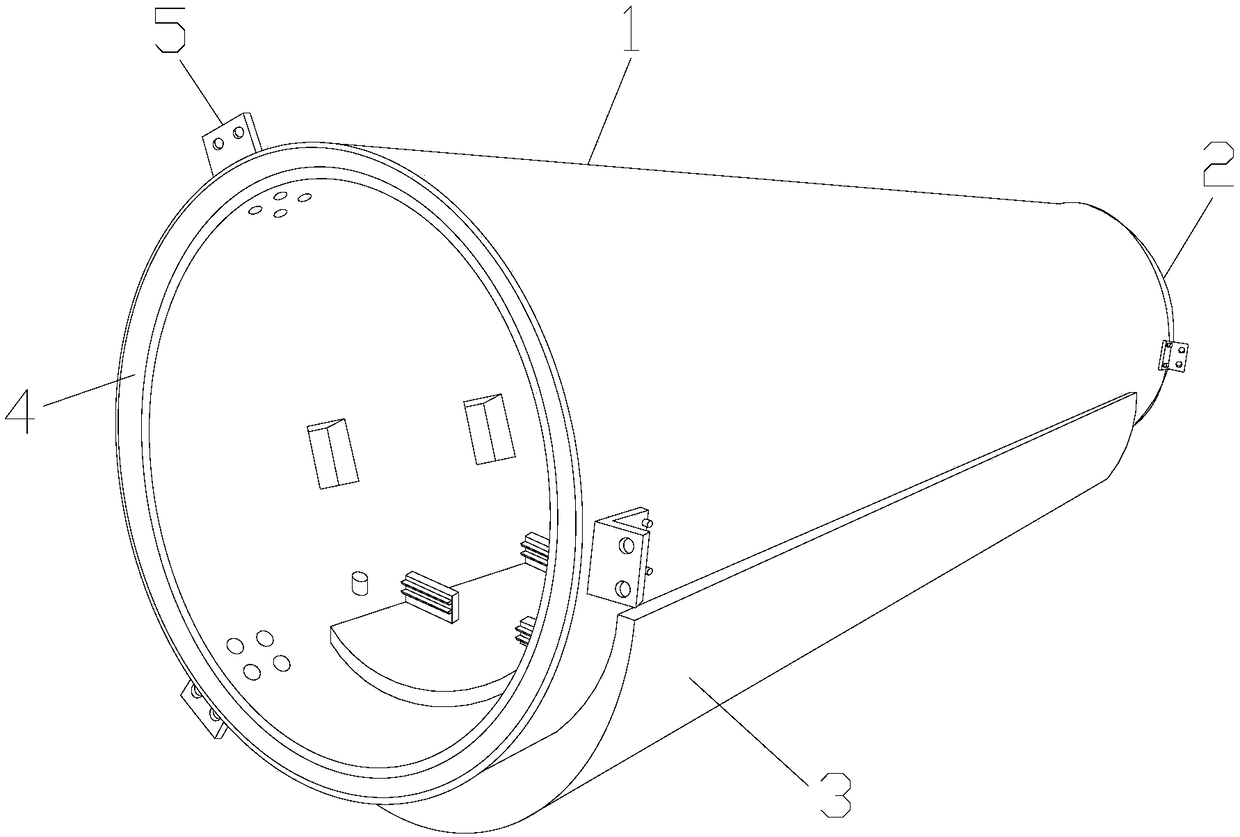

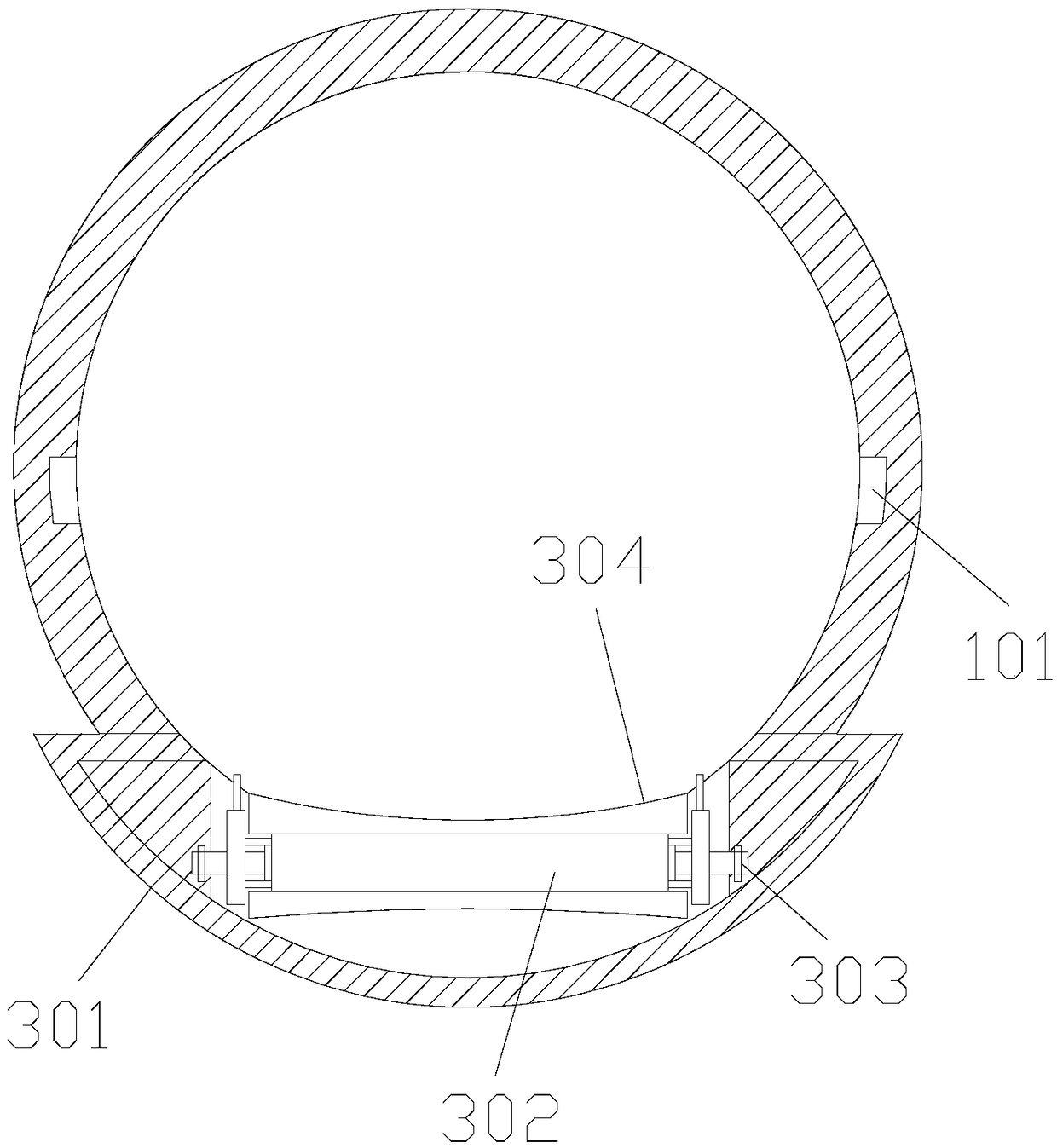

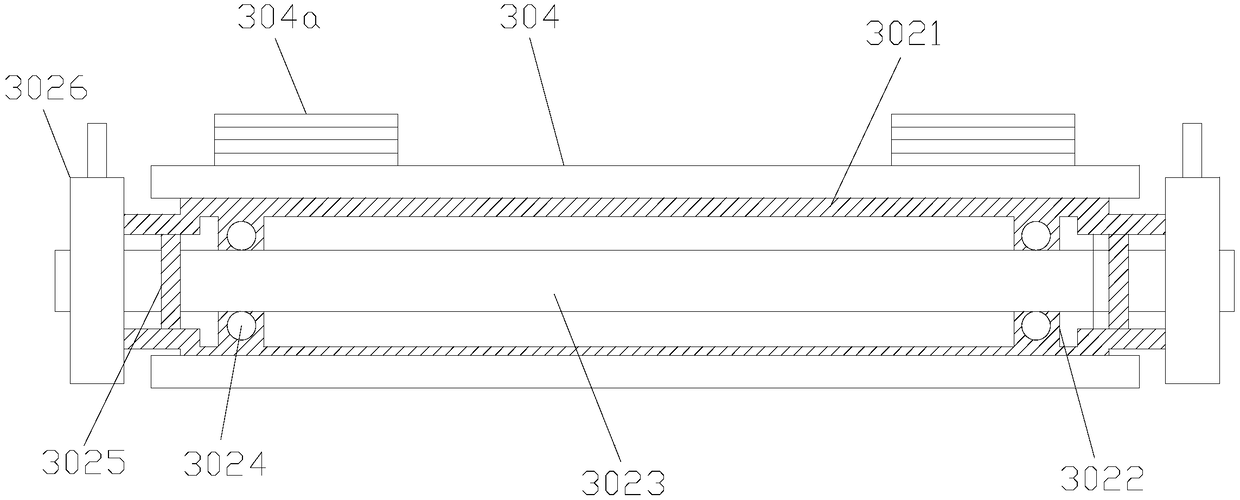

[0024] see Figure 1-Figure 6 , the present invention provides a tunnel booster escape pipeline for long-distance horizontal planes, the structure of which includes an escape pipeline 1, an annular bead 2, a sliding device 3, an annular groove 4, and an L-shaped mounting plate 5. The escape pipeline 1 is provided with an annular groove 4 on the front end, and three L-shaped mounting plates 5 are equidistantly arranged on the front surface of the escape pipe 1, and the escape pipe 1 and the L-shaped mounting plate 5 are movably connected. The rear end of the 1 is provided with an annular bead 2, the escape pipe 1 and the annular bead 2 are an integrated structure, the middle position of the bottom end of the escape pipe 1 is provided with a sliding device 3, the escape pipe 1 and the The sliding device 3 is connected, and the sliding device 3 is composed of a housing 301, a transmission mechanism 302, a bearing ring 303, and a transmission belt 304. Two bearing rings 303 are in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com