Labeling device of labeling facility

A labeling and equipment technology, applied in the directions of labeling machines, labels, packaging, etc., can solve the problems of affecting the quality of finished products, inconvenient installation and use, and high cost, and achieve the effect of ensuring operational stability, facilitating replacement and maintenance, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below, the present invention will be described in detail in conjunction with accompanying drawing and specific embodiment:

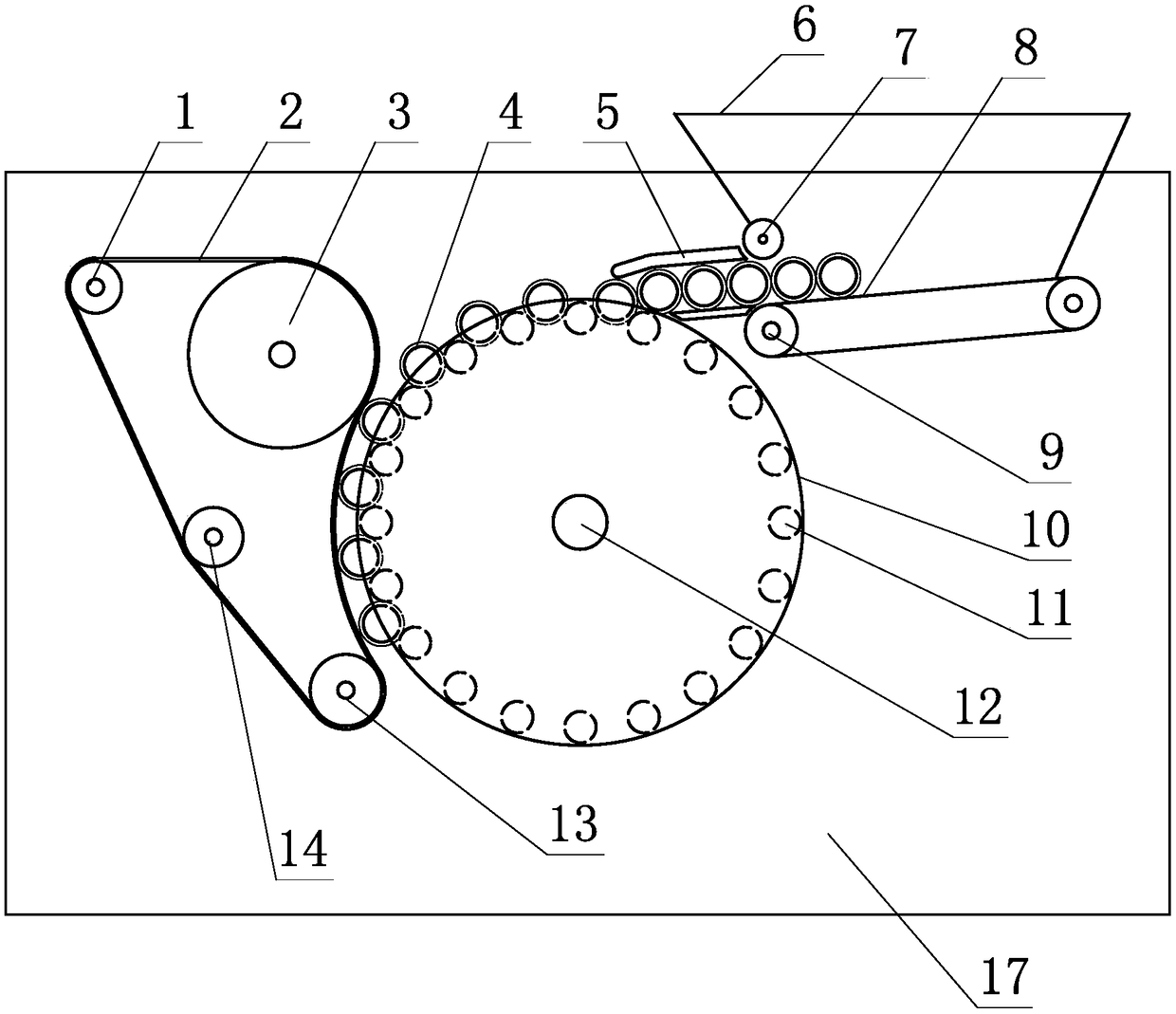

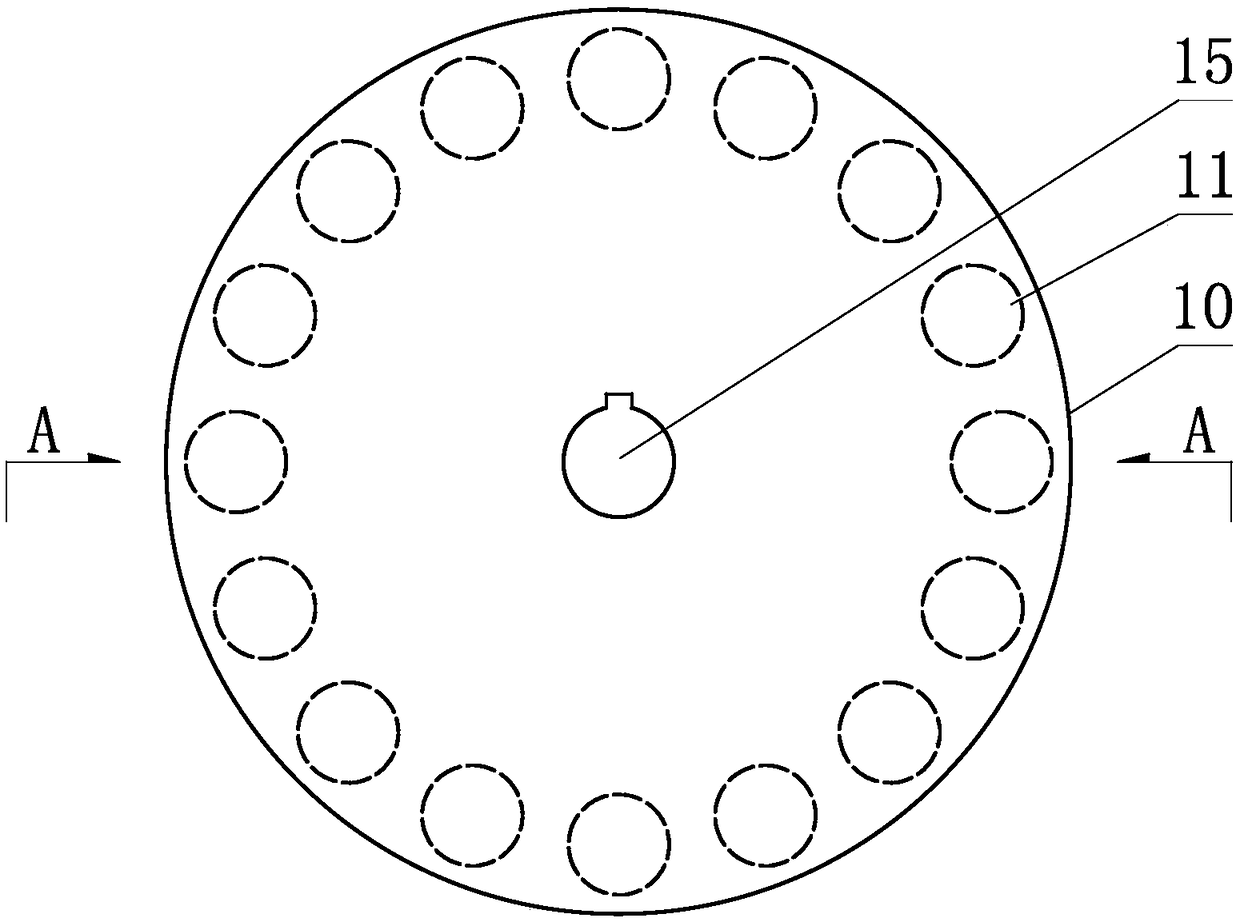

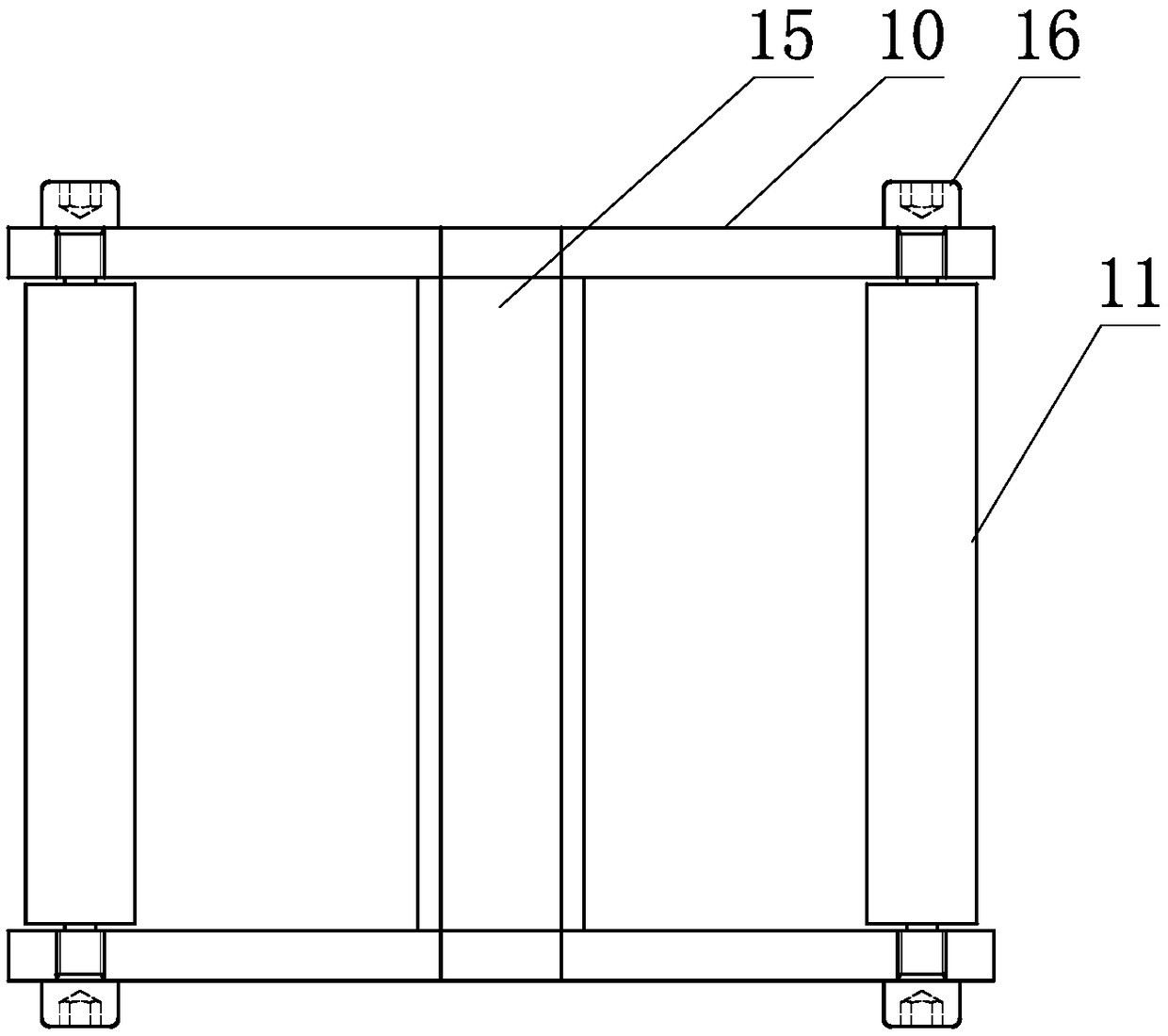

[0017] The present invention as figure 1 , figure 2 , image 3 As shown, its composition: consists of supporting shaft 1, labeling belt 2, vacuum drum 3, workpiece 4, pressing plate 5, hopper 6, rotating shaft 7, conveyor belt 8, roller 9, conveying roller 10, support shaft 11, roller support Axle 12, drive shaft 13, belt tensioner 14, shaft hole 15, fastening bolt 16, connecting plate 17 constitute.

[0018] The structural features of specific embodiments are:

[0019] A labeling device for labeling equipment is characterized in that it includes a workpiece conveying mechanism, a workpiece distribution mechanism and a labeling mechanism respectively arranged on the labeling equipment connecting plate 17, wherein,

[0020] The workpiece conveying mechanism is composed of a conveying roller 10 and several support shafts 11, and several said su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com