A trash can with downward discharge

A technology of a trash can and a barrel body, which is applied in the field of trash cans with downward discharge, can solve the problems of secondary pollution of the trash can environment, polluted trash cans, and the need for power supply, so as to protect from damage, improve service life, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

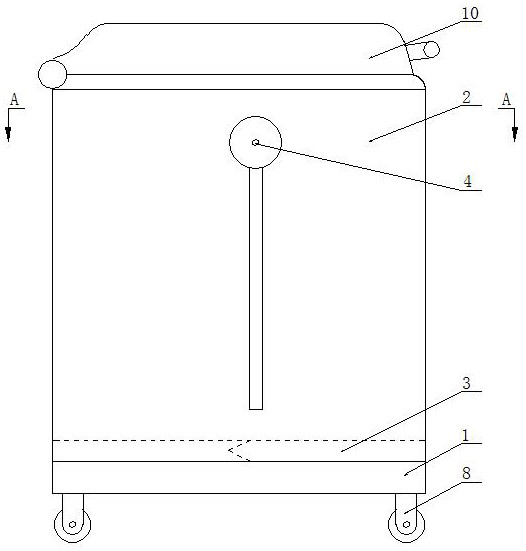

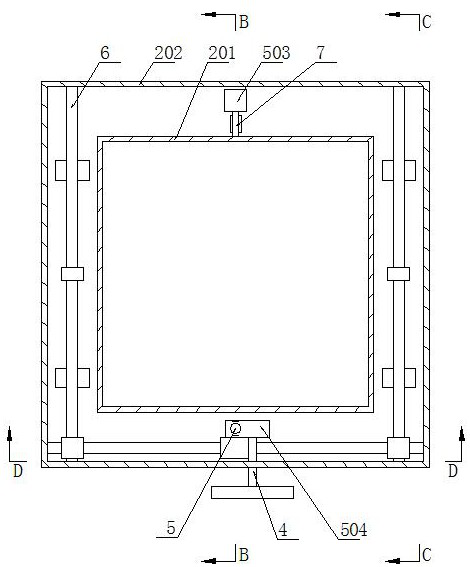

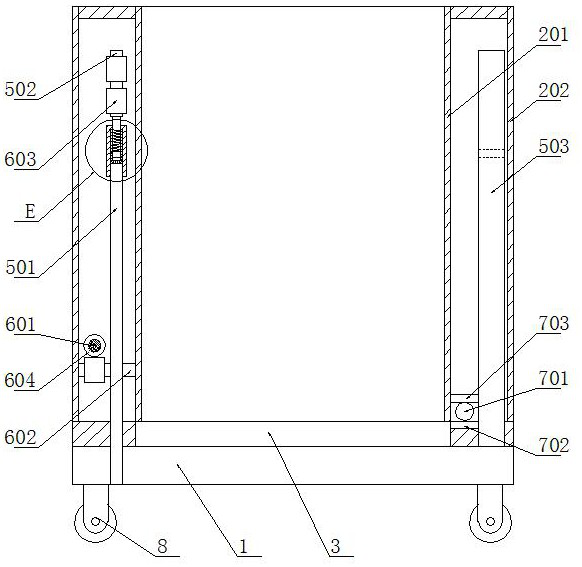

[0033] Such as Figure 1~Figure 8 As shown, a trash can for discharging materials downwards, the trash can includes a base 1, a barrel body 2 and a power mechanism, the base 1 is in the shape of a "mouth", the barrel body 2 is located above the base 1, and the barrel body 2 The inner barrel 201 and the outer barrel 202 form a "back" shape, and an interlayer is formed between the inner barrel 201 and the outer barrel 202. The bottom of the barrel body 2 is slidably provided with a bottom plate 3, and the power mechanism is located in the interlayer of the barrel body 2. The power mechanism includes Lifting mechanism 5, opening and closing mechanism 6 and interlocking mechanism 7, one side of the outer barrel 202 is longitudinally provided with a long groove, and a rotating shaft 4 is slid and rotated in the long groove, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com