Crane trolley set carrying and fixing device

A technology of fixing device and trolley group, which is applied in the directions of storage device, transportation and packaging, can solve problems such as gnawing on rails, and achieve the effect of reducing the loss of parts, good fixing effect, good safety and convenience of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

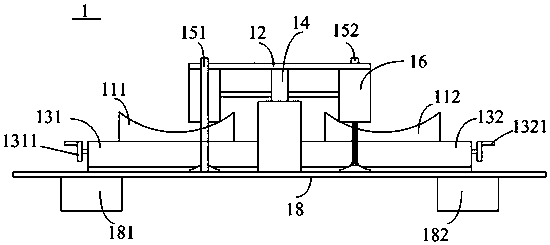

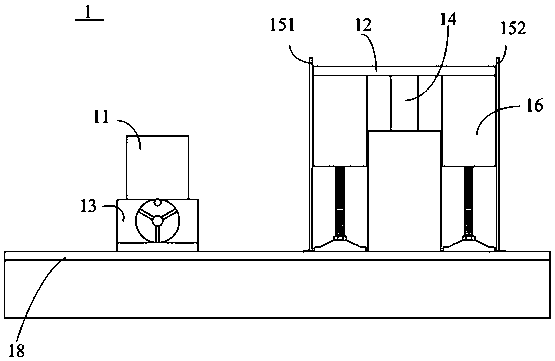

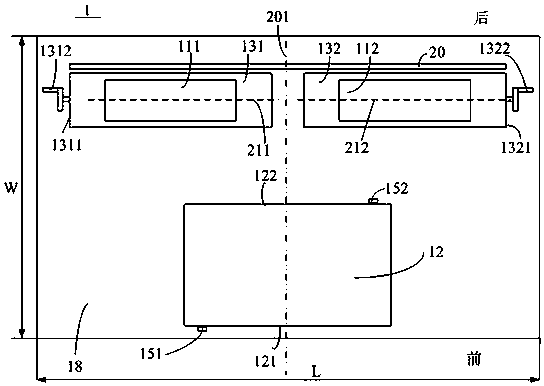

[0022] The following is a detailed description of the embodiments in conjunction with the accompanying drawings, but the provided embodiments are not intended to limit the scope of the present invention, and the description of the structure and operation is not intended to limit the order of execution, and any recombination of components The structure, the resulting device with equal efficacy, is within the scope of the present invention. In addition, the drawings are for illustration purposes only and are not drawn to original scale. For ease of understanding, the same components will be described with the same symbols in the following description.

[0023] Terms used throughout the specification and claims, unless otherwise noted, generally have each term's ordinary meaning as used in the field, in this disclosure and in the special context. Certain terms used to describe the present disclosure are discussed below or elsewhere in this specification to provide those skilled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com