An intelligent material handling device for underground logistics

A technology of intelligent materials and handling devices, which is applied in the direction of storage devices, transportation and packaging, conveyors, etc., can solve the problems that the surface of the trolley is difficult to tilt, the transport area of the trolley is fixed, and it is inconvenient to carry, so as to reduce friction and improve transmission accuracy and the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

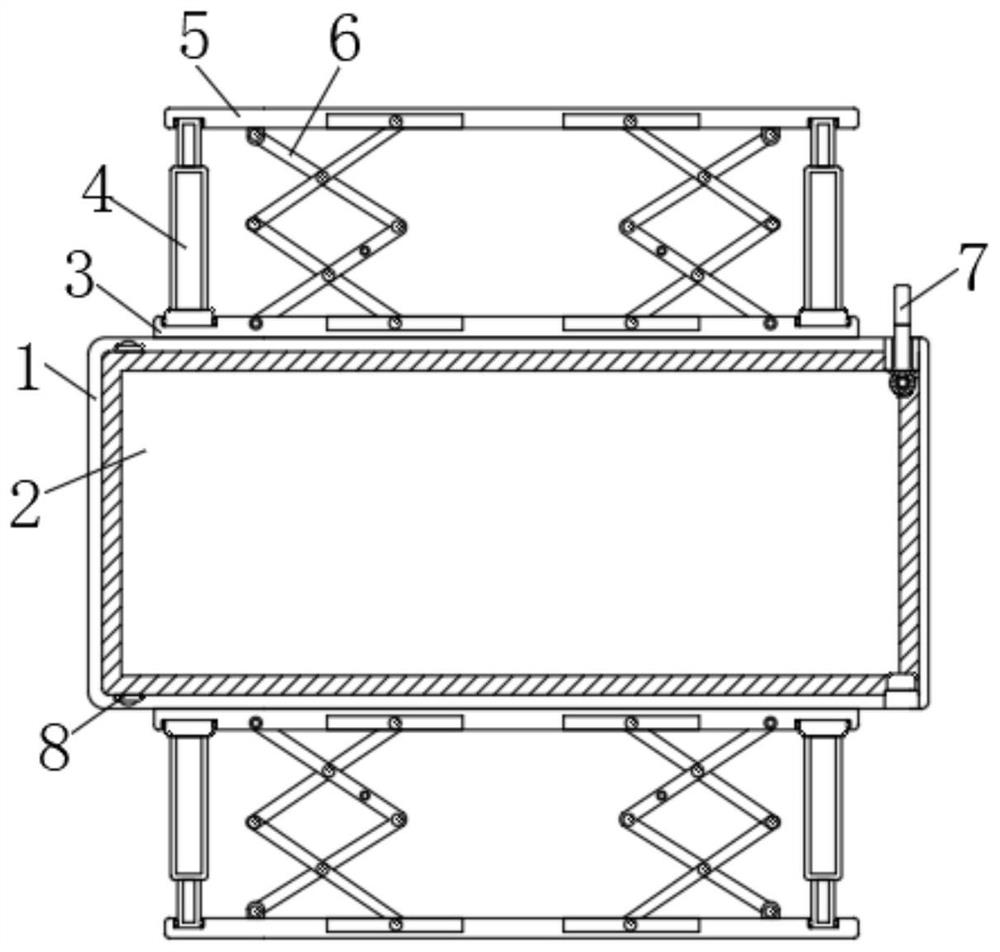

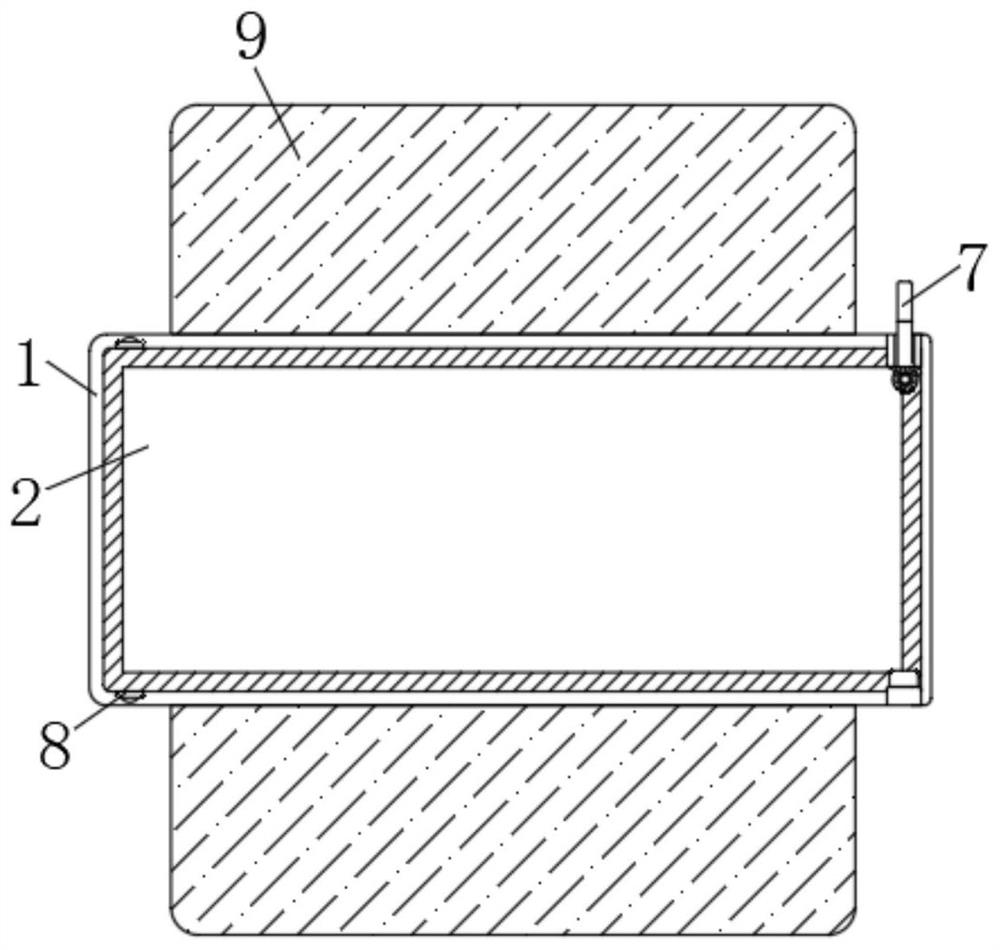

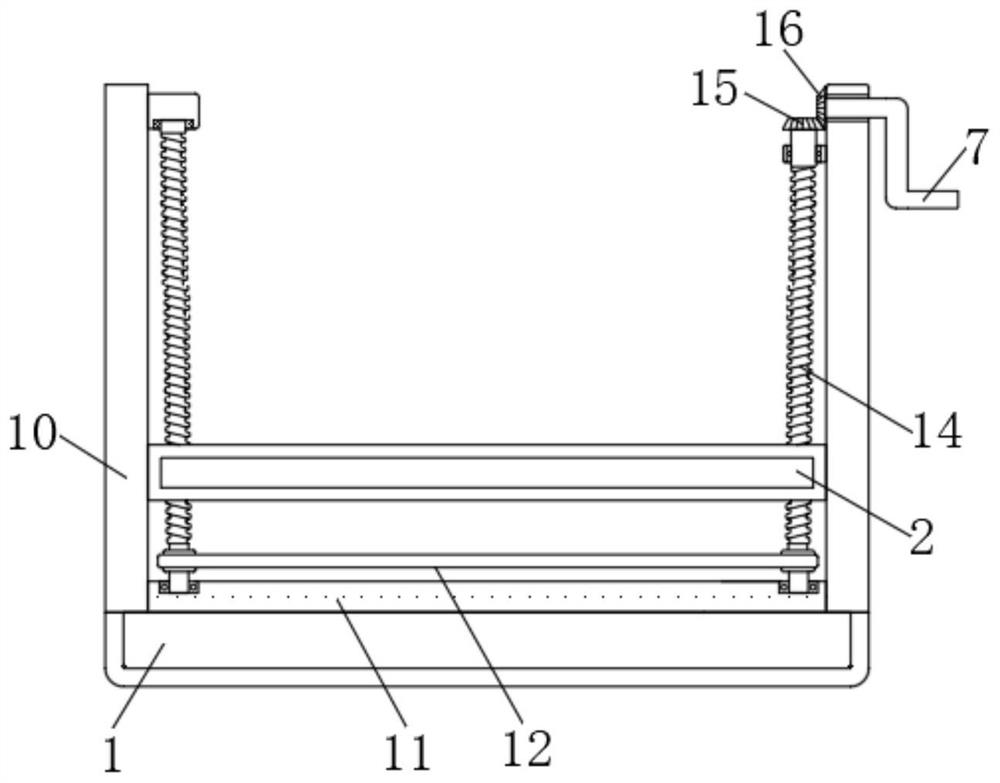

[0039] see Figure 1-4 , an intelligent material handling device for underground logistics, comprising a moving mechanism 1 and a telescopic rod 4, the right side of the moving mechanism 1 is connected with a fixed frame 10, and the inner side of the fixed frame 10 is provided with a third connecting block 11, the third connecting block 11 Screw rods 14 are installed on both sides through the bearing seat, and the lower surface of the screw rod 14 is sleeved with a belt mechanism 12. There are two sets of screw rods 14, and the screw rods 14 are symmetrically distributed inside the two sides of the placement plate 2. The two sets of screw rods 14 are simultaneously The rotation makes the placing plate 2 run smoothly, the surface of the screw rod 14 is sleeved with the placing plate 2 , and the left side of the placing plate 2 is hinged with the first fixing block 8 .

[0040] The inside of the right side of the placement plate 2 is provided with a cavity, and the inner wall of...

Embodiment 2

[0045]An intelligent material handling device for underground logistics, comprising a moving mechanism 1 and a telescopic rod 4, the right side of the moving mechanism 1 is connected with a fixed frame 10, and the inner side of the fixed frame 10 is fixed with a third connecting block 11, the third connecting block 11 Screw rods 14 are installed on both sides through bearing seats, and the lower surface of the screw rods 14 is sleeved with a belt mechanism 12. There are two sets of screw rods 14, and the screw rods 14 are symmetrically distributed inside the two sides of the placement plate 2. The two sets of screw rods 14 rotate simultaneously. To make the placement board 2 run smoothly, the surface of the screw rod 14 is sleeved with the placement board 2 , and the left side of the placement board 2 is hinged with the first fixing block 8 .

[0046] The inside of the right side of the placement plate 2 is provided with a cavity, and the inner wall of the cavity is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com