A kind of copolyether ester and its preparation method and application

A technology of copolyetherester and methyl ester, applied in the field of copolyetherester and preparation, can solve the problems of complex molding process, unsatisfactory flame retardancy, complicated steps, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

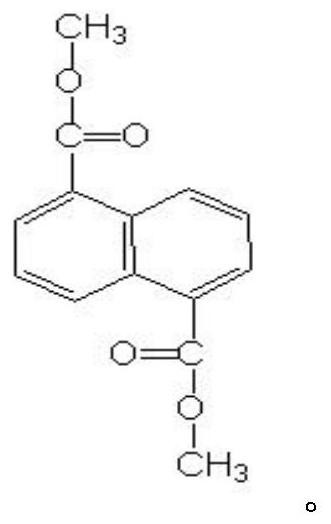

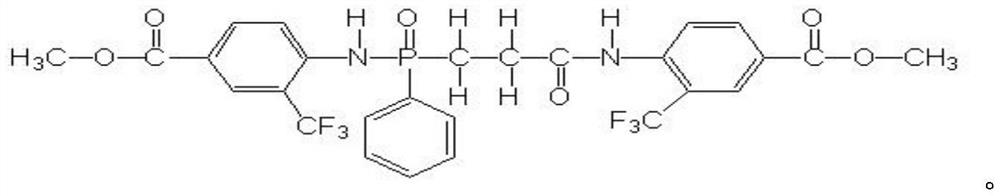

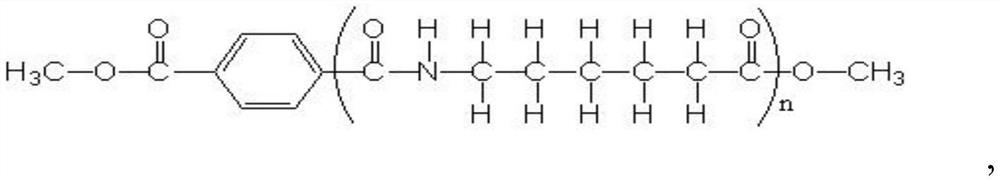

[0036] Dimethyl naphthalate (3530g), p-(methyl-phenyl-3-trifluoromethyl-4-amino)-(methyl-phenyl-3-trifluoromethyl-4-amidoethyl ) phenylphosphine oxide (650g), low molecular weight nylon 6 dimethyl ester (650g), 1,4-butanediol (3500g), polytetrahydrofuran ether (1600g), tetrabutyl titanate (40g), antioxidant Add SEED (20g) and nucleating agent NAV101 (10g) into the polymerization kettle, and obtain copolyetherester through transesterification reaction and polycondensation reaction. The hardness of the copolyetherester is D52, and the number average molecular weight Mn is about 31000. The physical and mechanical properties of copolyether esters are shown in Table 1.

Embodiment 2

[0038] Dimethyl naphthalate (3930g), p-(methyl-phenyl-3-trifluoromethyl-4-amino)-(methyl-phenyl-3-trifluoromethyl-4-amidoethyl ) phenylphosphine oxide (500g), low molecular weight nylon 6 dimethyl ester (500g), 1,4-butanediol (3700g), polytetrahydrofuran ether (1300g), tetrabutyl titanate (40g), antioxidant Add SEED (20g) and nucleating agent NAV101 (10g) into the polymerization kettle, and obtain copolyetherester through transesterification reaction and polycondensation reaction. The hardness of the copolyetherester is D56, and the number average molecular weight Mn is about 32000. The physical and mechanical properties of copolyether esters are shown in Table 1.

Embodiment 3

[0040] Dimethyl naphthalate (3130g), p-(methyl-phenyl-3-trifluoromethyl-4-amino)-(methyl-phenyl-3-trifluoromethyl-4-amidoethyl ) phenylphosphine oxide (800g), low molecular weight nylon 6 dimethyl ester (800g), 1,4-butanediol (3500g), polytetrahydrofuran ether (1700g), tetrabutyl titanate (40g), antioxidant Add SEED (20g) and nucleating agent NAV101 (10g) into the polymerization kettle, and obtain copolyetherester through transesterification reaction and polycondensation reaction. The hardness of the copolyetherester is D50, and the number average molecular weight Mn is about 31000. The physical and mechanical properties of copolyether esters are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com