Device for detecting cloth defects

A technology for detecting devices and defects, which is applied in measuring devices, analyzing materials, and optically testing flaws/defects, etc. It can solve problems such as easy to ignore, high operating intensity, and dead angles, so as to facilitate manual operation, change the irradiation range, and adaptability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

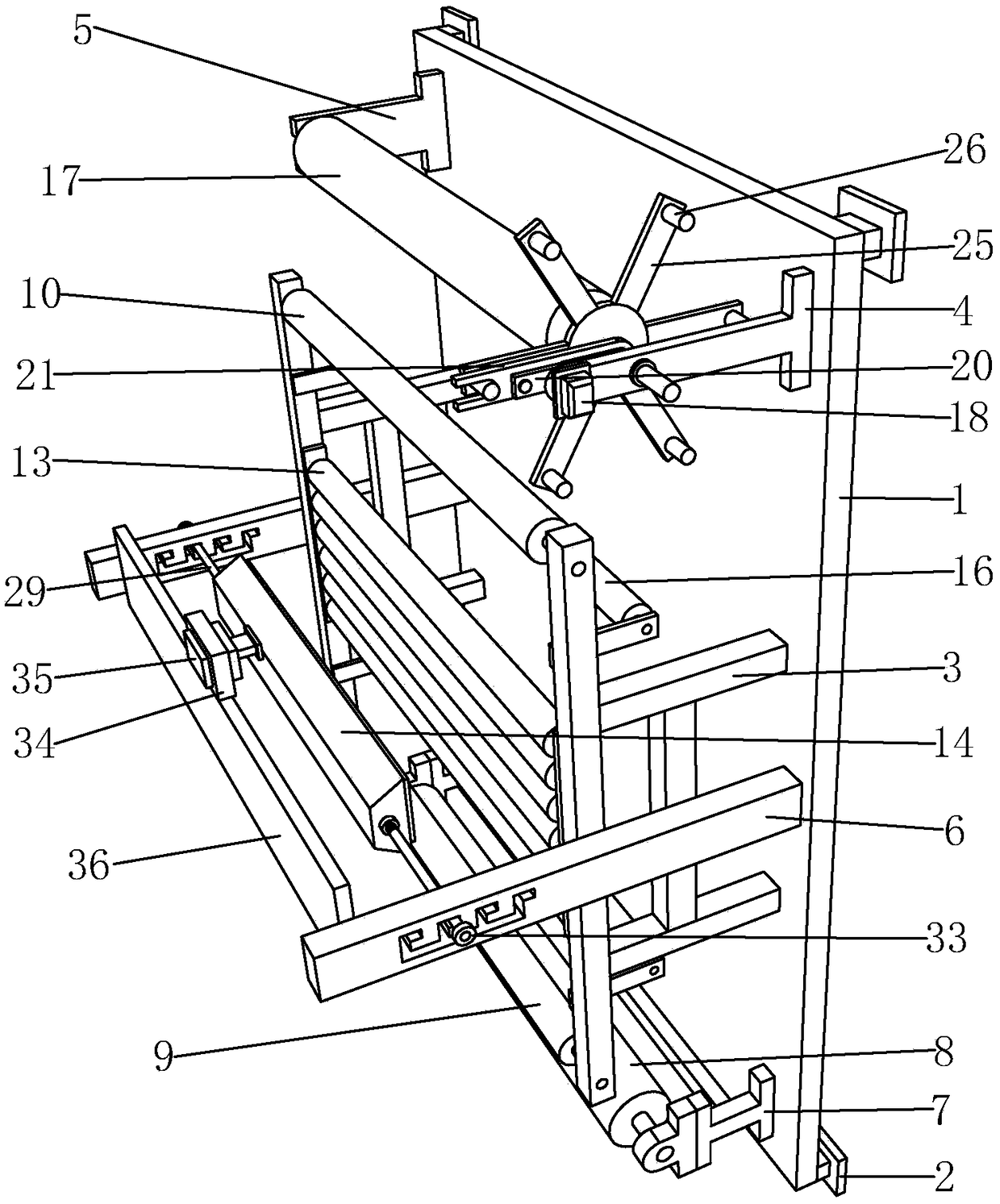

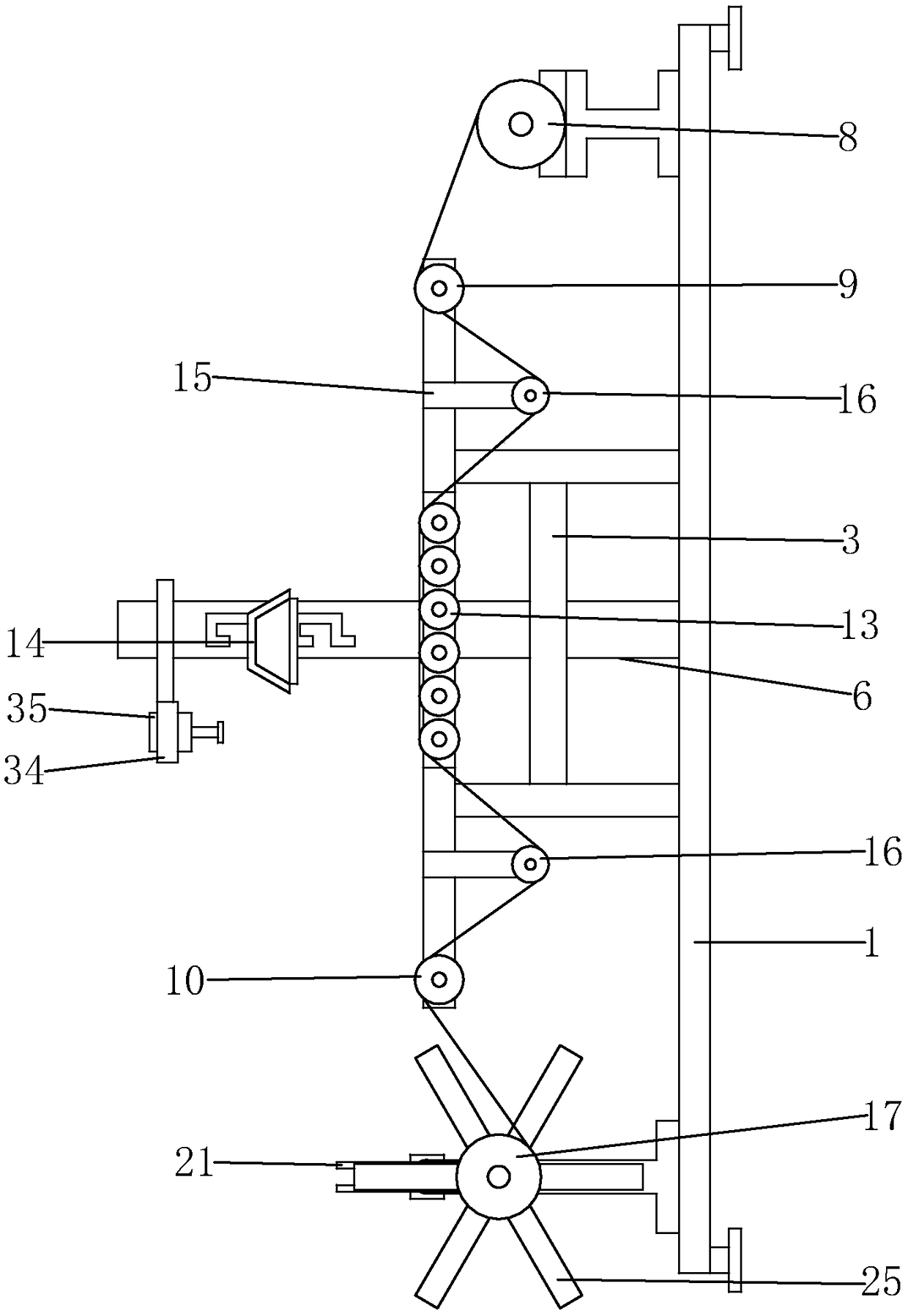

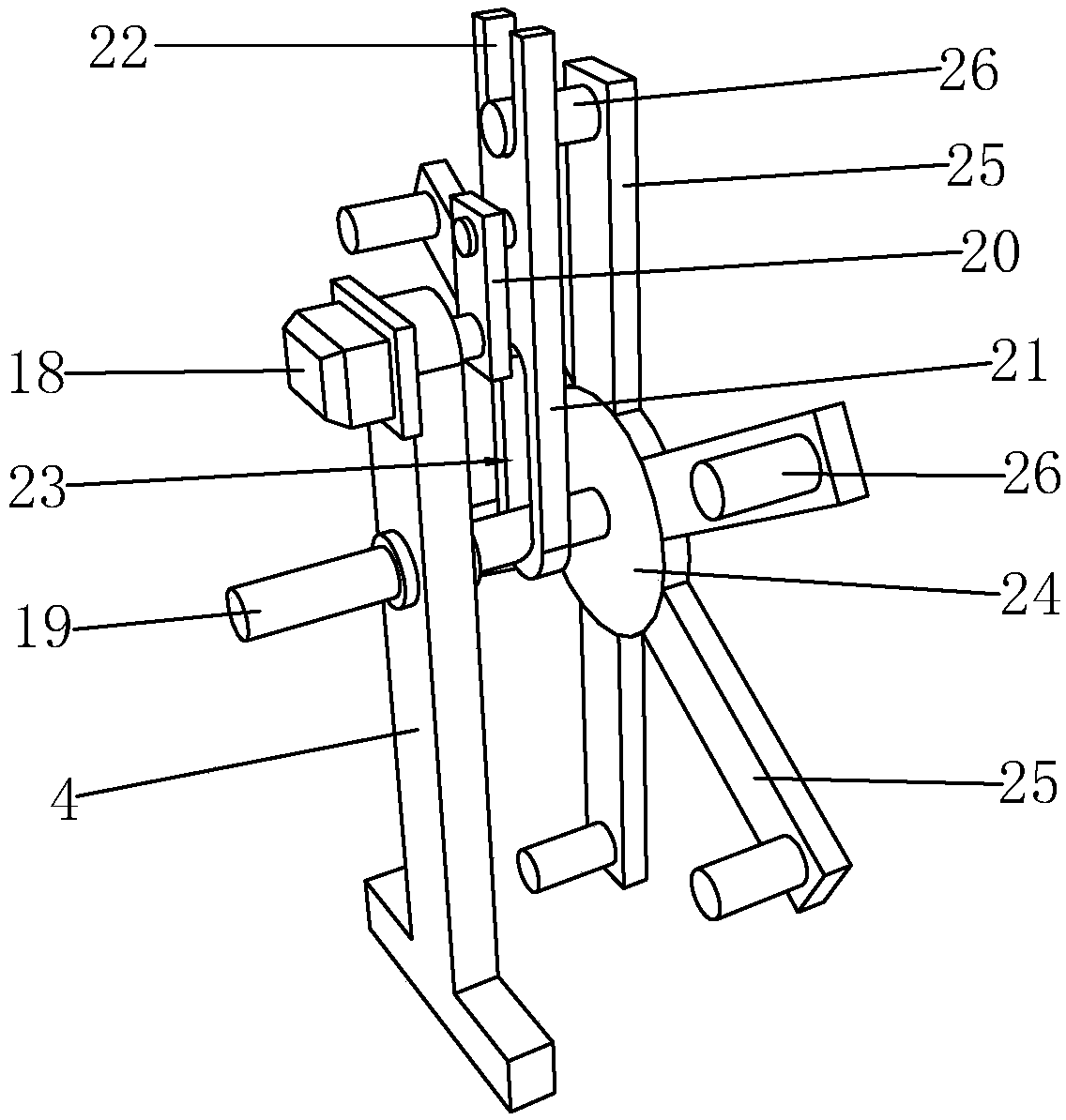

[0027] like Figure 1 to Figure 6As shown, it is a fabric defect detection device according to the present invention, which includes a working platform 1 and supporting feet 2. The supporting feet 2 are arranged on the four corners of the bottom surface of the working platform 1, and the working platform 1 is provided with a support frame 3 and a fixed bracket 4 respectively. , bracket 5, vertical plate 6 and I-shaped support 7, vertical plate 6 is fixed on one side of support frame 3, vertical plate 6 and support frame 3 are connected as a whole, contain mutually, are not easy to separate, thereby improved vertical plate 6 1. The firmness of the support frame 3 installed on the working platform 1. A cloth release roller 8 is arranged between the I-shaped supports 7, and a cloth feed roller 9, a cloth guide roller 10 and a delivery roller group are respectively arranged between the support frames 3, and the cloth delivery roller 9 and the cloth guide roller 10 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com