Safety socket

A safety socket, safe technology, applied in electrical components, coupling devices, circuits, etc., can solve problems such as electric shock accidents, easy access to exposed metal inserts, and children's curiosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

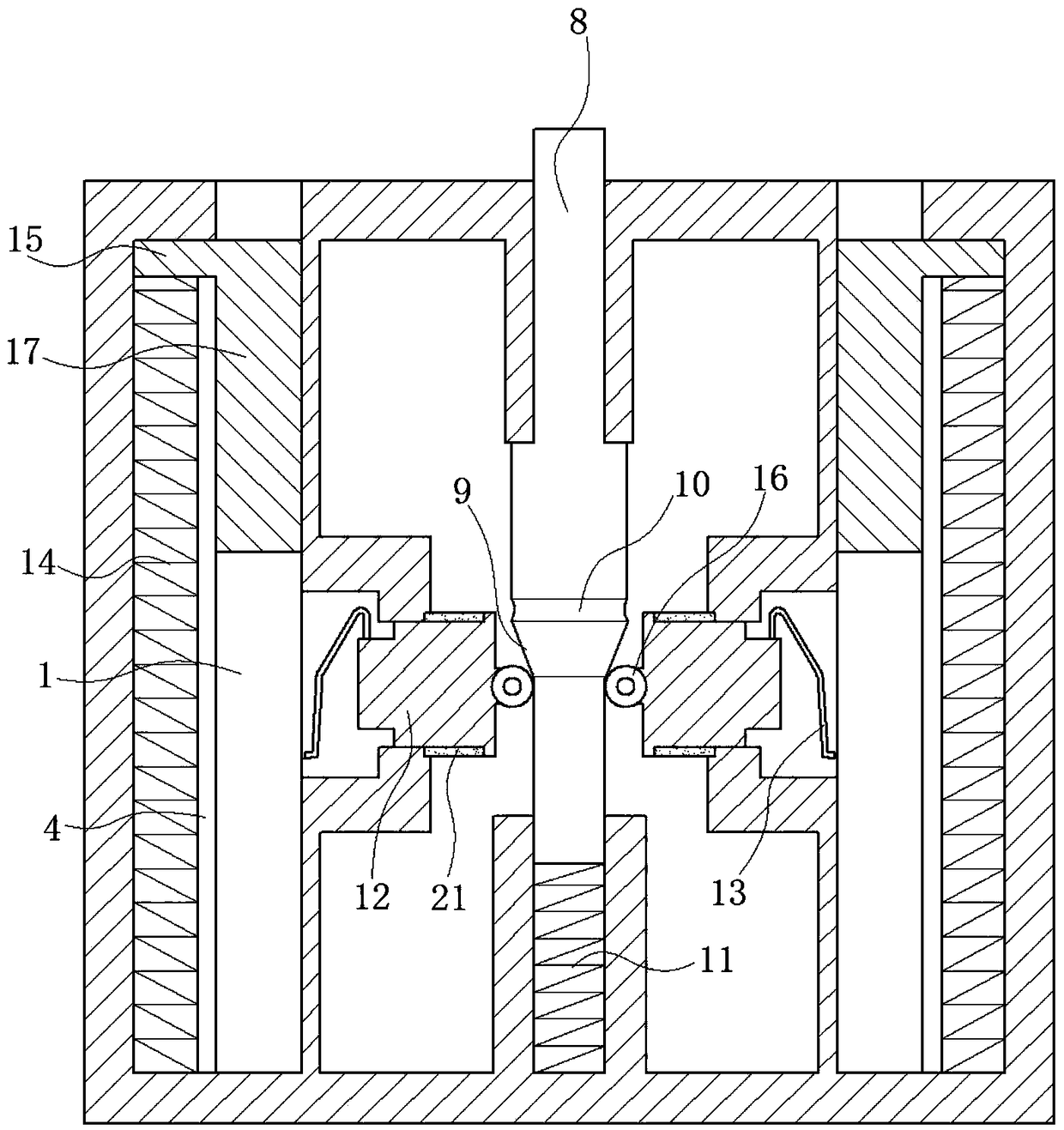

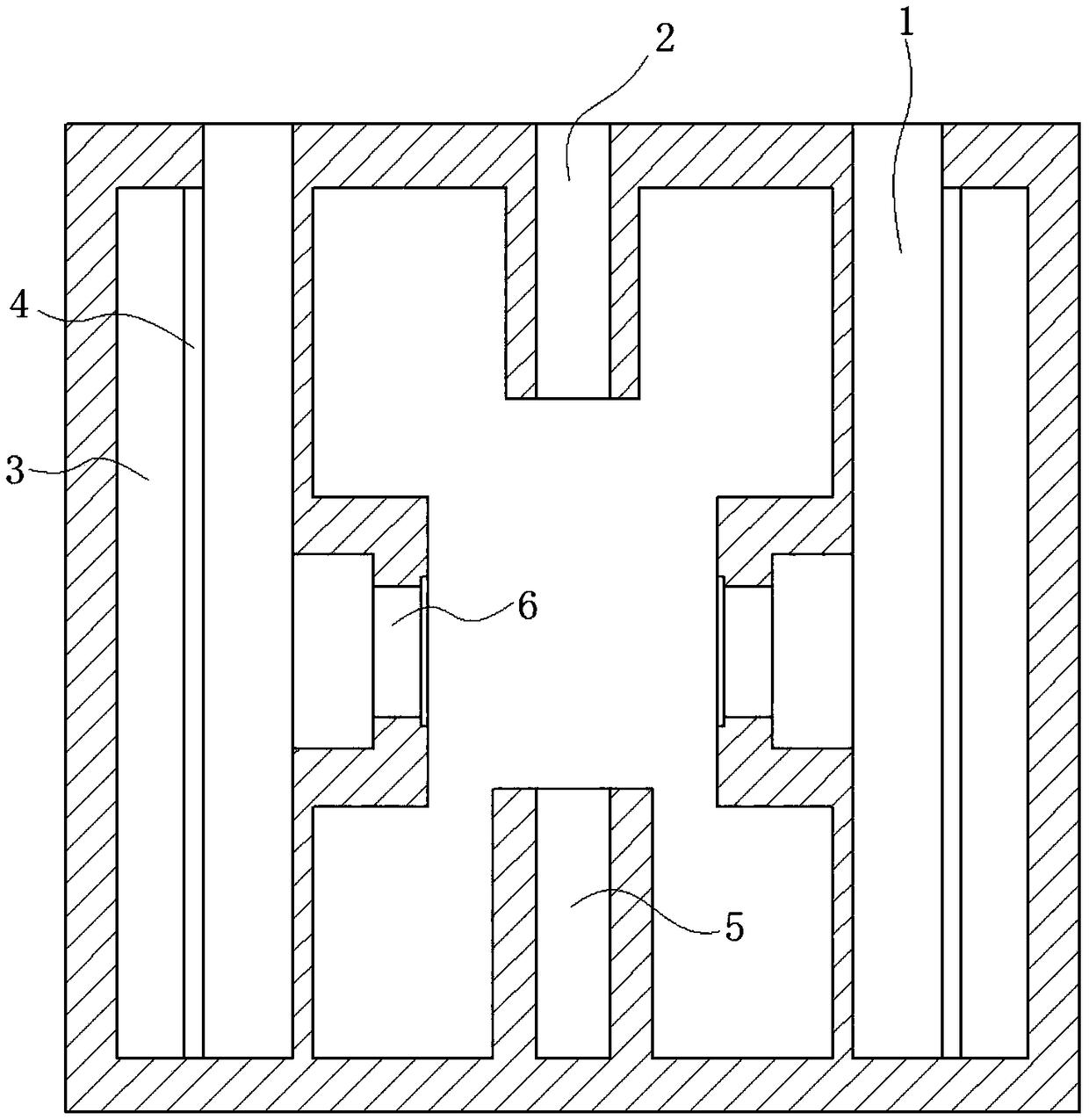

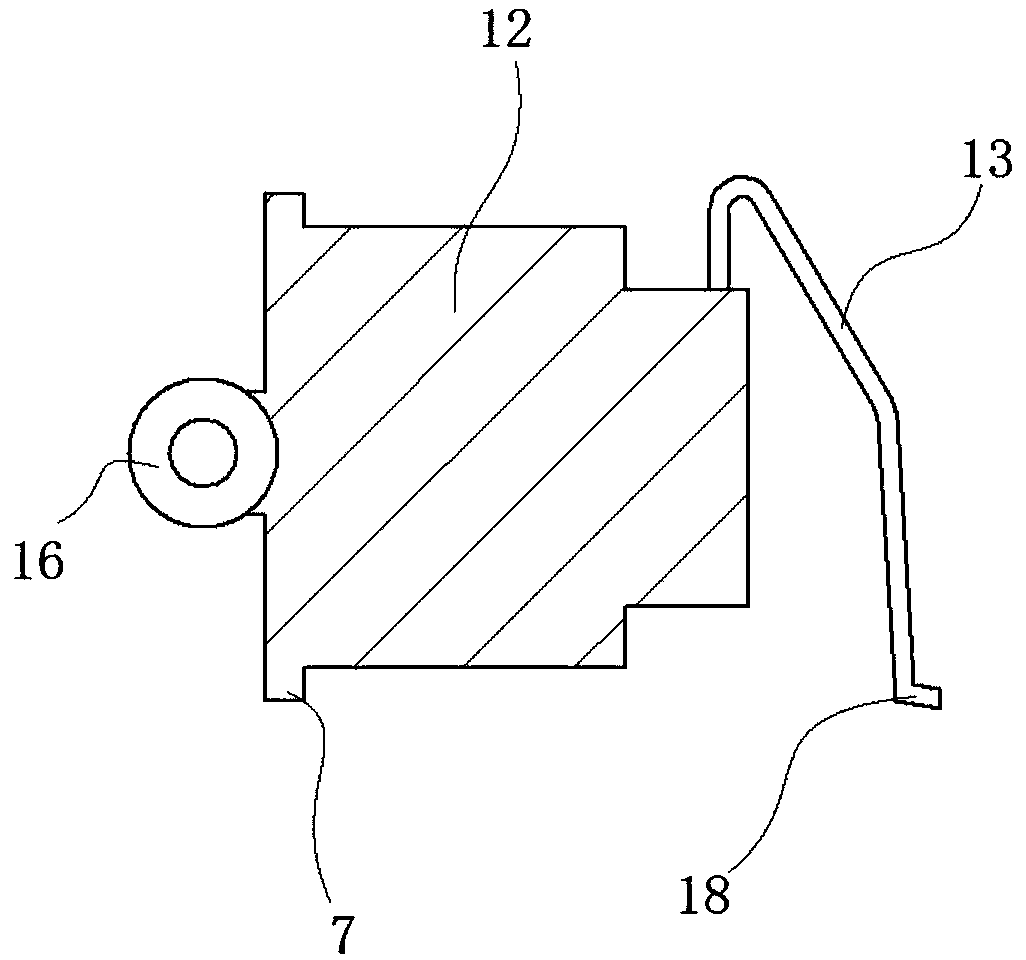

[0028] The embodiment of the present invention includes a socket body. The upper end surface of the socket body is provided with a socket 1 and a pin hole 2. The pin holes 2 are distributed between the same group of sockets 1; A safety sliding hole. A sliding block 12 is fitted in the safety sliding hole. The sliding block 12 includes a tail end on the side close to the pin hole 2 and a head end on the side close to the jack 1. The head end is provided with a spring contact piece 13 connected to the power supply. The tail end is provided with a contact wheel 16 that abuts against the tapered section 9, and the sliding block 12 is also provided with a first spring 21 that pushes to the side of the pin hole 2; the pin hole 2 is fitted with an upwardly abutting spring pin , The spring pin includes a pin shaft 8 slidably fitted with the pin hole 2 and a third spring 11 that abuts the pin shaft 8 upwards. Below the pin hole 2 is provided a guide hole 5 adapted to the lower end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com