A precision compensation method for a split resolver for a position marker

A resolver and precision compensation technology, which is applied in the direction of instruments, general control systems, adaptive control, etc., can solve problems such as poor precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

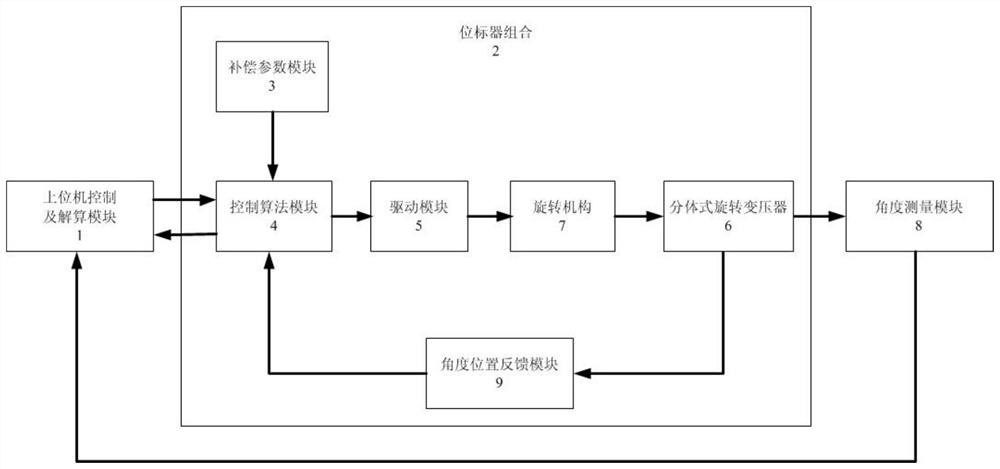

[0022] A device and method for improving the compensation of a split resolver, comprising: a host computer control and calculation module 1, a position marker combination 2, a compensation parameter module 3, a control algorithm module 4, a drive module 5, a split resolver 6, a rotary Mechanism 7, angle measurement module 8 and angle position feedback module 9.

[0023] Wherein, the compensation parameter module 3 , the control algorithm module 4 , the driving module 5 , the split resolver 6 , the rotating mechanism 7 and the angle position feedback module 9 belong to the position marker combination 2 .

[0024] The two communication ends of the upper computer control and calculation module 1 are respectively connected to the communication port of the angle measurement module 7 at the position marker combination 2, the angle measurement module 8 is fixed on the rotating mechanism 7, and the split resolver 6 is coaxially installed On the rotating mechanism 7 and rotate thereupo...

Embodiment 2

[0026] Using the compensation method of the above-mentioned position marker with a coaxially installed split resolver precision compensation system, the specific steps are:

[0027] Step 1: Fix the angle measurement module 8 on the rotating mechanism 7 .

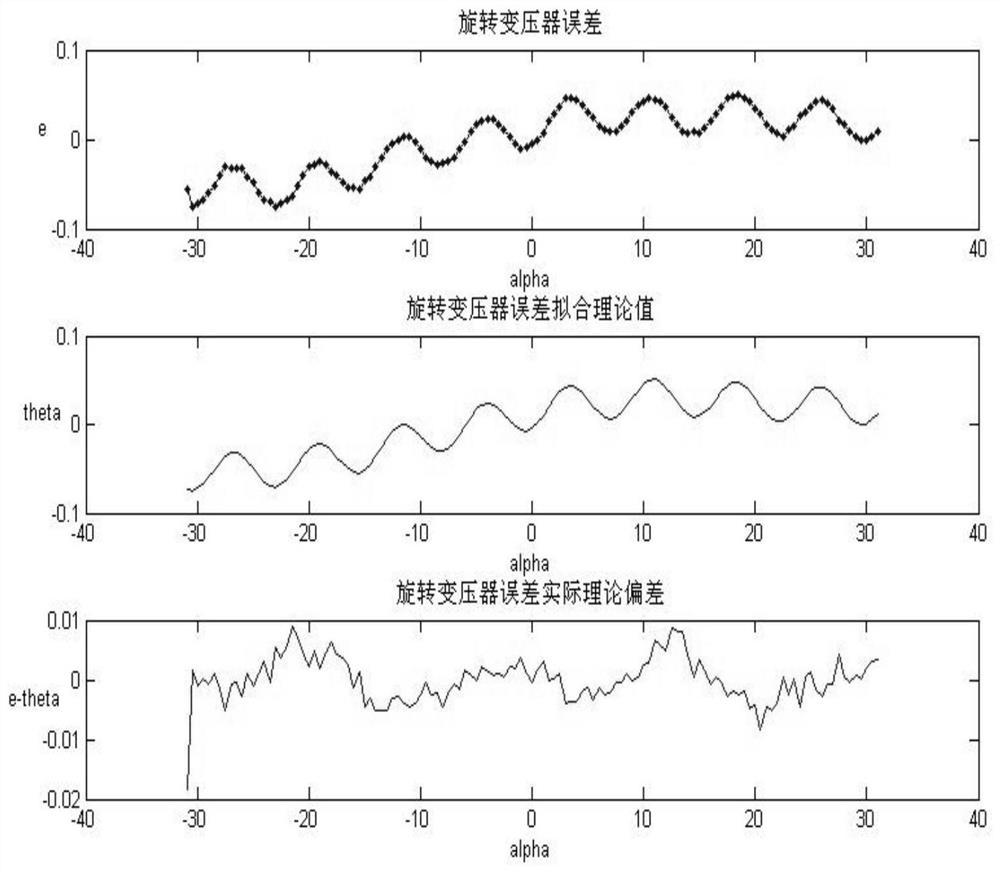

[0028] Step 2: The upper computer control and calculation module 1 presets the angle through communication with the position marker combination 2 and reads the electrical feedback angle α of the split resolver 6 1 At the same time, the upper computer control and calculation module 1 reads the actual rotation mechanical angle β of the split resolver 6 and the rotation mechanism 7 through communication with the angle measurement module 8 1 , the host computer control and calculation module 1 calculates the electrical feedback angle α of the split resolver 6 1 and the actual rotation mechanical angle β 1 Error e 1 = β 1 -α 1 .

[0029] Step 3: By repeating the above process, averagely take n angles within the range of mot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com