Method for regulating micro print ink dot position and size

A kind of ink dot and tiny technology, applied in the electrical recording process using the charge pattern, the equipment of the electric recording process using the charge pattern, and the electrography, etc., can solve the problems that affect the printing quality, are not proportional, and errors, etc., to achieve Effects that improve print quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings.

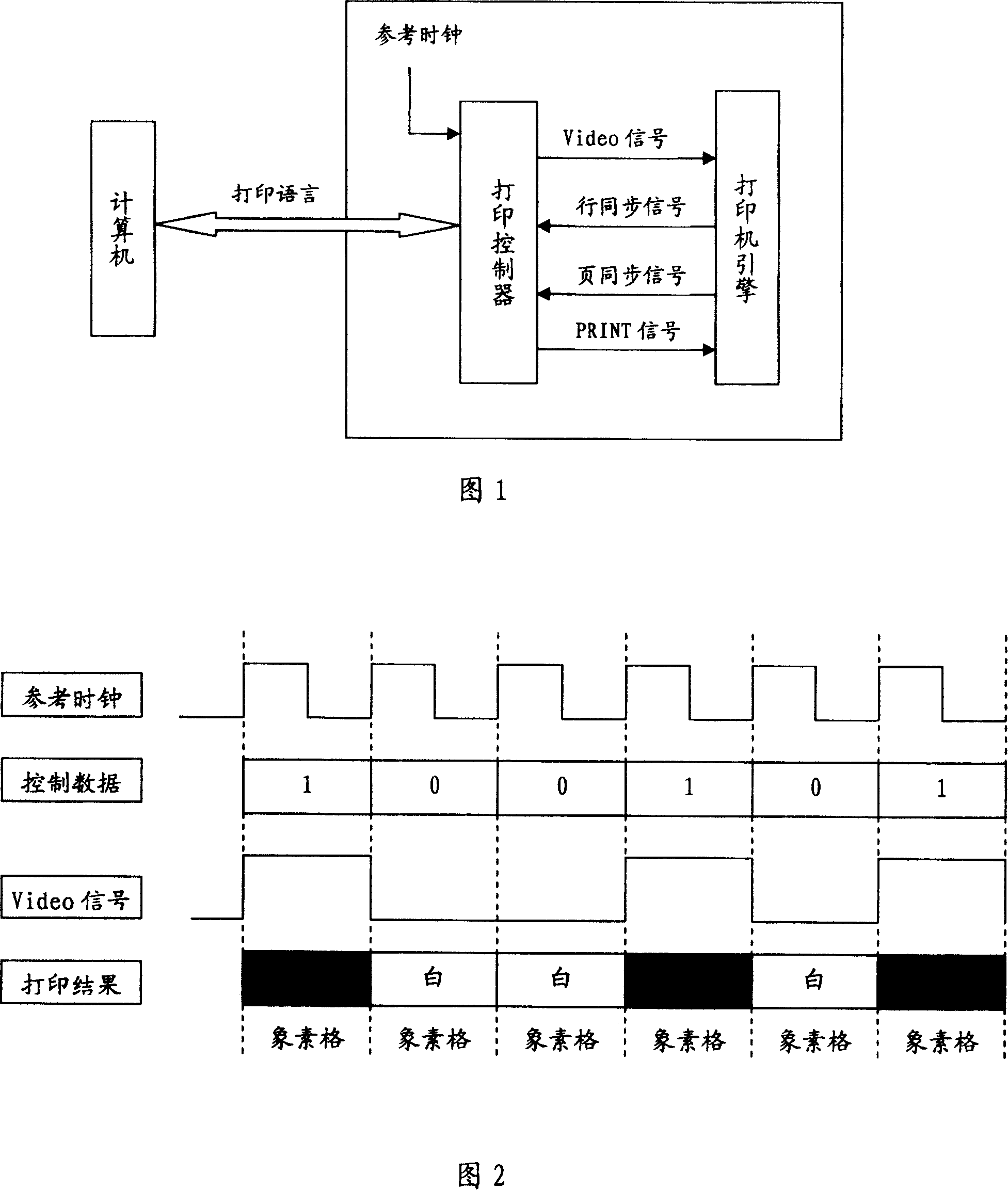

[0046] Figure 1 describes a block diagram of an ordinary laser printer, which includes two parts: the printer engine and the print controller. The reference clock is a synchronous control signal that controls the output data of the print controller and the synchronization of the laser beam of the printer engine. Its period is equal to the laser beam scanning of the printer. The time of a complete pixel, such as the printer laser beam scanning a complete pixel time is 50ns, then the reference clock cycle is also 50ns. When printing, the print controller receives the page printing data from the computer, interprets the page printing data into a raster dot matrix, and converts the raster dot matrix into a Video signal through control signals such as page synchronization signal, line synchronization signal, and PRINT signal, thereby controlling the printer The engine finis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com