Processing technology for reducing residual oxygen for packaging machine

A technology of processing technology and residual oxygen, which is applied in packaging, transportation packaging, packaging protection, etc., can solve the problems of material preservation, affecting the residual oxygen content of bags, affecting the residual oxygen content of packaging bags, etc., and achieve the effect of nitrogen stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

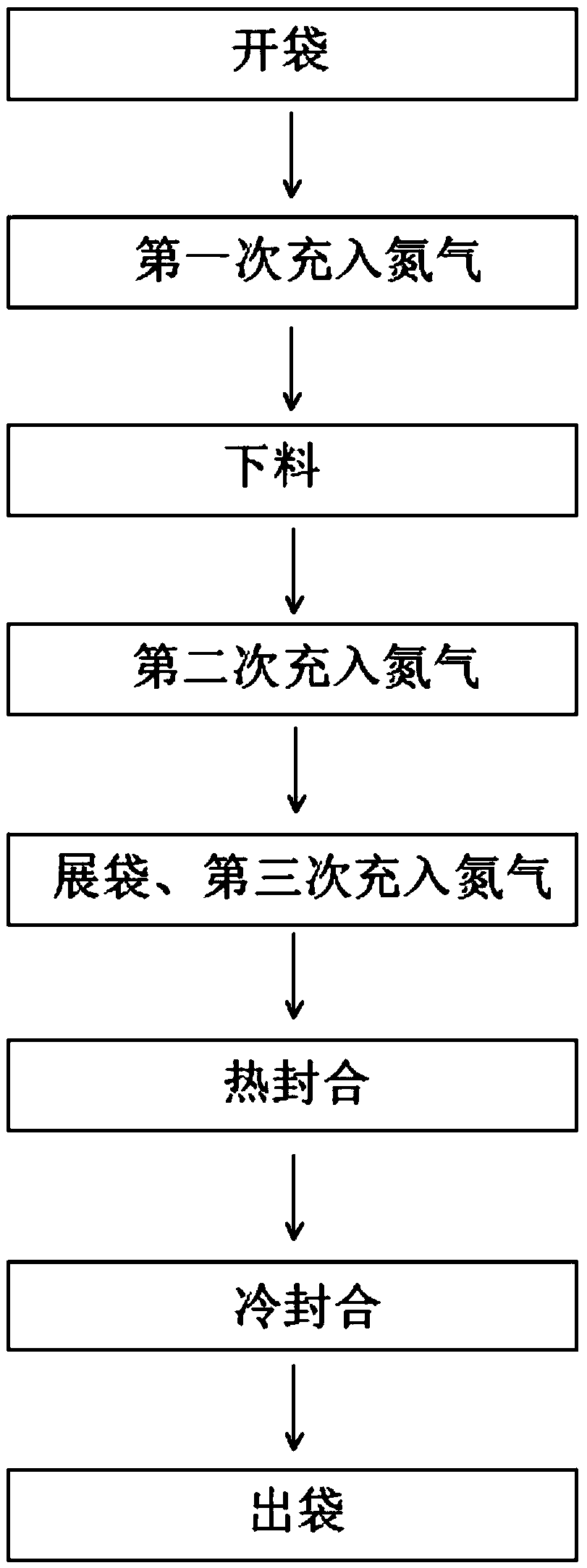

[0025] Such as figure 1 As shown, the processing technology of the packaging machine to reduce the residual oxygen content includes the following steps:

[0026] Transport the packaging bag to the bag opening station, and fill the bag with nitrogen; the packaging bag is conveyed to the bag opening station under the action of the conveying device, and the bag is filled with nitrogen to replace the air in the bag for the first time after opening , before the packaging bag is transported to the bag opening station, the packaging bag can be made into a roll film bag or a prefabricated bag. Since the mass of nitrogen is less than that of air when it is filled with nitrogen, during the movement, Nitrogen gas will move upwards, thereby leaving the packaging bag, so that the packaging bag needs to be filled with nitrogen several times, and the bag opening sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com