Continuous mining method with rigid and soft strip filling without coal pillars in the goaf of inclined coal seam

A goaf, no coal pillar technology, applied in the fields of backfill, ground mining, mining equipment, etc., can solve problems such as coal loss in underground coal mines, achieve continuous mining without coal pillars, ensure control effects, and reduce backfill costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

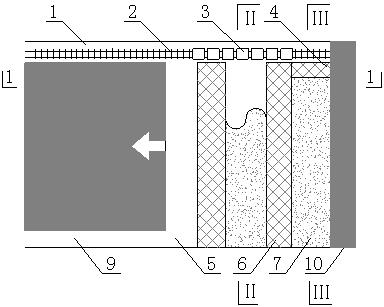

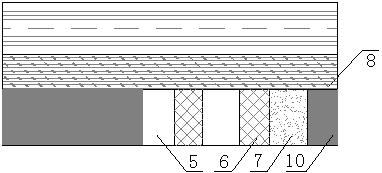

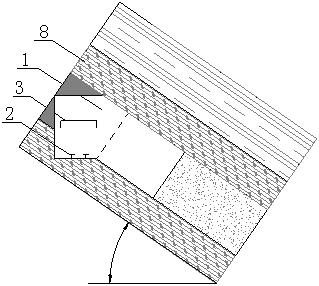

[0021] In the figure, the operation steps of the non-pillar-free continuous mining method are as follows:

[0022] ① After the working face 5 of the inclined coal seam is recovered from the cut hole, the overdue working face 5 is about 30-60m, and the track level roadway 1 is reinforced with anchor cables;

[0023] ② When the advancing distance of the inclined coal seam working face 5 is close to the initial caving step of the direct roof 8, fill the goaf with paste strips for the first time. The lower end is to the non-recovery side of the transport entryway 9, the upper end of the strip 6 is to the recovery side of the track entryway 1, the width of the strip 6 is 3-10m, and the paste material is aeolian sand, cement, fly ash and water reducer Composition of the mixture, the water-cement ratio is 0.5;

[0024] ③ The aeolian sand is transported to the goaf via the rail entry 1 by using the overturning van type mine car 3, and the aeolian sand is unloaded into the non-recover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com