Ore lifting system, ore lifting control method and mining system for mining of metal nodules

A control method and technology for nodules, which are applied in the fields of mining minerals, special mining, and earth-moving drilling, etc., can solve the problems of impeller wear and nodules breakage, fragmentation, low mining efficiency and resource recovery rate, and easy entanglement of cables, so as to improve mining efficiency. , large particle size, reducing wear and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

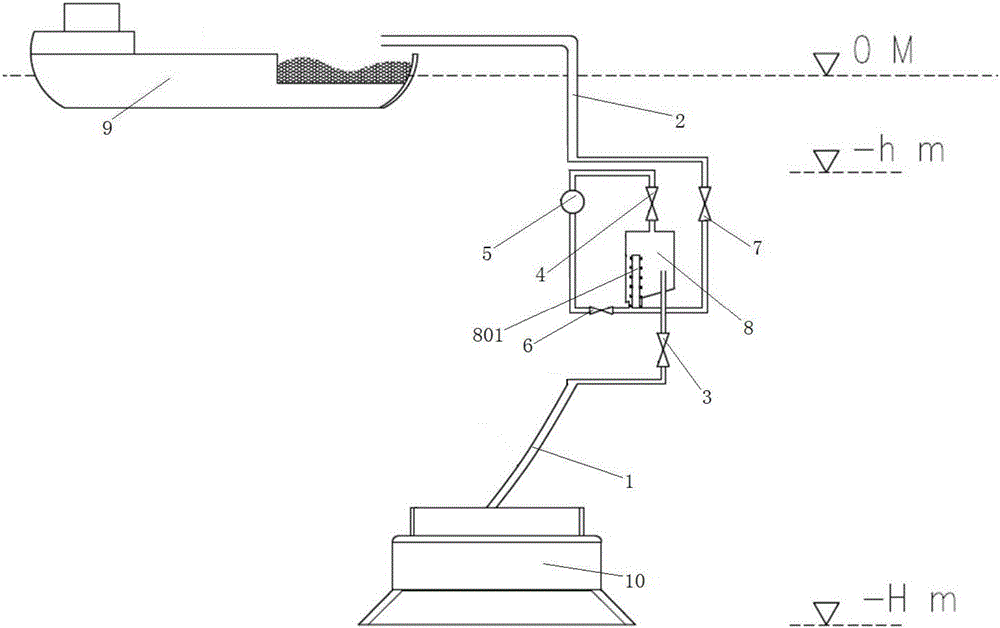

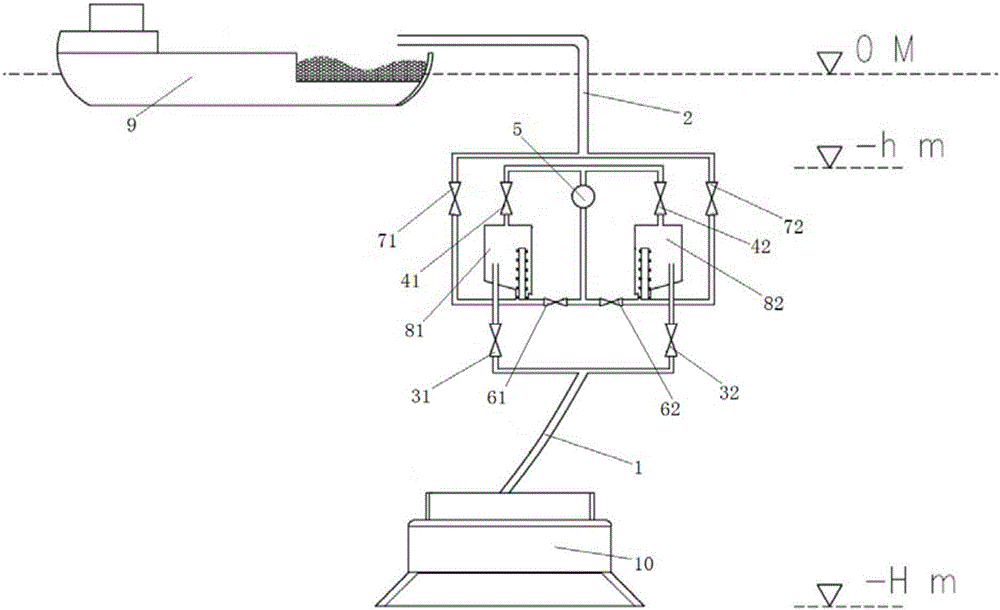

[0018] The present invention is realized like this, as figure 1 As shown, the ore lifting system for metal nodule mining includes ore suction hose 1, ore lifting hose 2, and an ore lifting drive assembly connected between ore suction hose 1 and ore lifting hose 2, which is characterized in that , the ore lifting drive assembly includes a submersible sewage pump 5 and a separator 8 located under the sea surface, the separator 8 communicates with the ore suction hose 1 through the ore suction control valve 3, and the separated water outlet at the top of the separator 8 is connected to the submerged sewage The water inlets of the pumps 5 are connected through the pumping control valve 4, and the nodule discharge outlet at the bottom of the separator 8 is connected with the water outlet of the submersible sewage pump 5 and the ore lifting hose 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com