Sealing device of rolling rotor compressor and rolling rotor compressor

A rolling rotor type, sealing device technology, applied in the sealing device of piston pump, rotary piston type machinery, machine/engine, etc., can solve problems such as leakage, and achieve the effect of improving sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

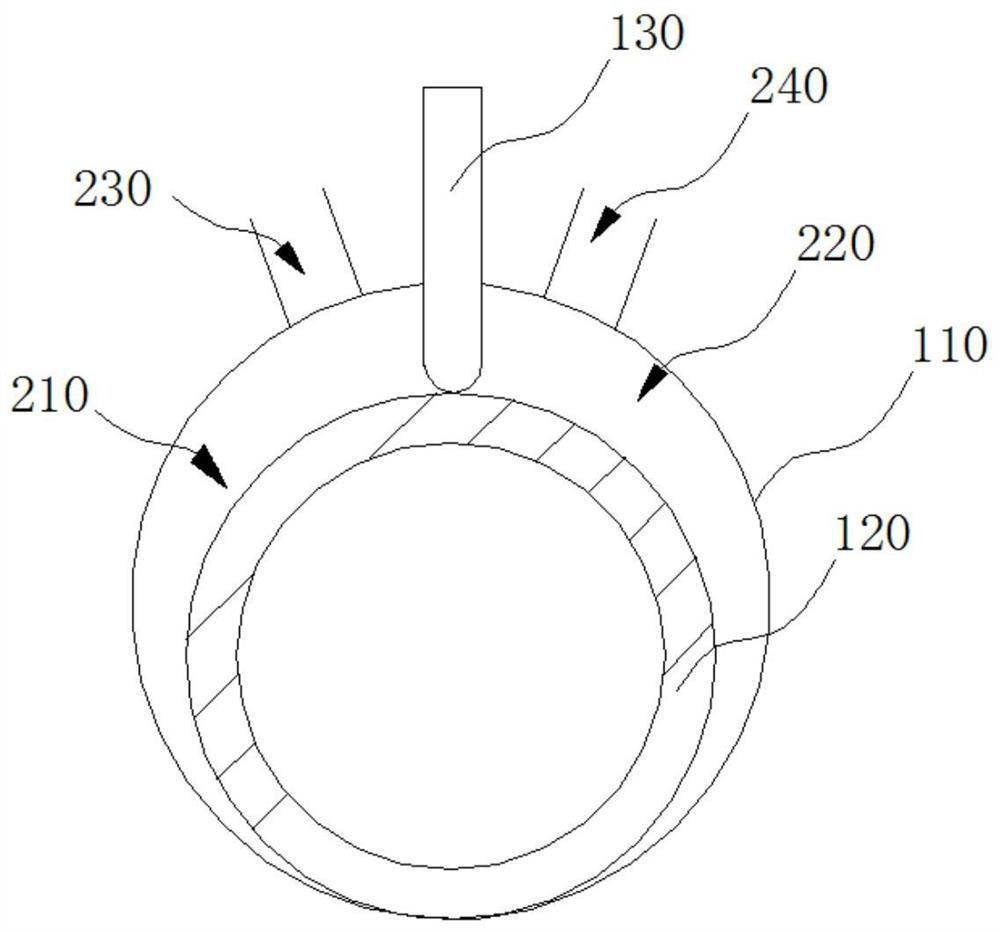

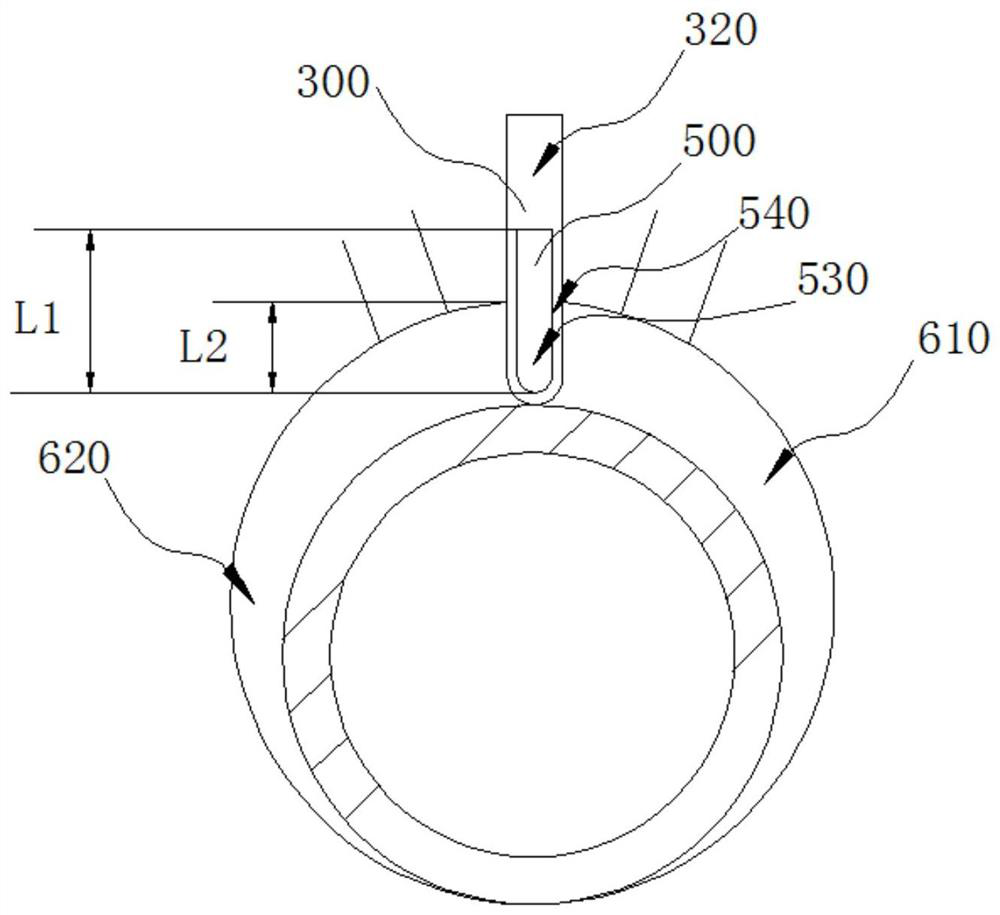

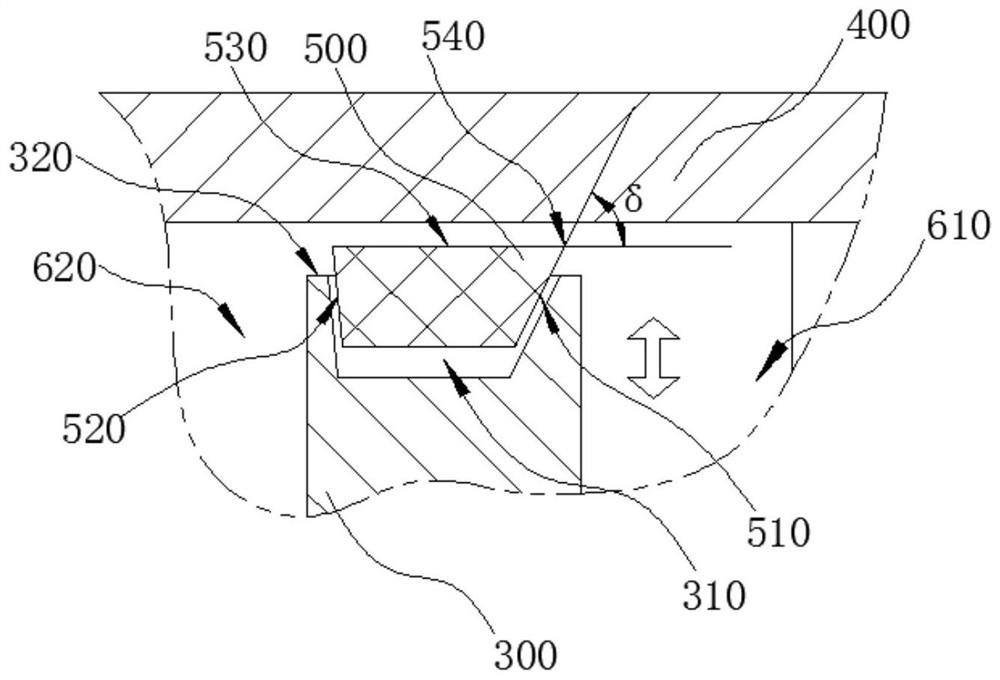

[0050] figure 2 It is a schematic cross-sectional view in one direction of the sealing device of the rolling rotor compressor according to an embodiment of the present invention, image 3 It is a partial cross-sectional schematic view of the sealing device of the rolling rotor compressor in another direction according to an embodiment of the present invention. refer to figure 2 with image 3 , this embodiment provides a sealing device for a rolling rotor compressor, and the sealing device includes a groove 310 and a sealing member 500 . The rolling rotor compressor includes a cylinder head cover 400, a sliding vane 300 and a closed cavity (not shown in the figure). The sliding vane 300 divides the airtight cavity into a high-pressure chamber 610 and a low-pressure chamber 620 , and the high-pressure chamber 610 and low-pressure chamber 620 are respectively located on both sides of the sliding vane 300 . The sliding piece 300 has a first end surface 320 facing the cylinde...

Embodiment 2

[0060] This embodiment provides a sealing device for a rolling rotor compressor, and the sealing device includes a groove and a sealing member. The rolling rotor compressor includes a cylinder end cover, a sliding vane and a closed cavity. The sliding vane divides the airtight cavity into a high-pressure chamber and a low-pressure chamber, and the high-pressure chamber and low-pressure chamber are respectively located on both sides of the sliding vane. The cylinder end cover has a second end surface facing the sliding piece. The groove is opened on the second end surface. The seal is installed in the groove. The seal has opposing first and second sides, and a sealing surface facing the cylinder head cover. One side of the sealing surface is connected to the first side, and the other side of the sealing surface is connected to the second side. The first side is close to the high pressure cavity, and the second side is close to the high pressure cavity. The included angle δ...

Embodiment 3

[0063] This embodiment also provides a rolling rotor compressor. Figure 4 It is a cross-sectional view of a rolling rotor compressor according to an embodiment of the present invention. refer to Figure 4 , the rolling rotor compressor includes the above-mentioned sealing device of the rolling rotor compressor.

[0064] Preferably, the number of the cylinder end covers 400 is two, and a sealing device of the rolling rotor compressor is provided between the two cylinder end covers 400 and the sliding vane 300 . Especially for horizontal rolling rotor compressors, seals 500 are provided on the two end faces of the sliding vane 300 facing the cylinder end cover 400, which can effectively prevent the refrigerant from passing through the sliding vane 300 and the cylinder end cover 400 from the high pressure chamber. The gap between leaks into the low pressure chamber. Of course, in other embodiments, refer to Figure 4 For example, a vertical scrolling rotor compressor, the ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com