Soil layered rotary tillage test device

A test device and soil layering technology, applied in the direction of adjustment devices, lifting devices of agricultural machinery, shovels, etc., can solve the problems of large error between test results and actual operation results, energy consumption of compound rotary tillage machinery and research on operation quality cannot be realized, etc. To achieve the effect of convenient cutter tooth structure and quantity, lower design cost, and convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

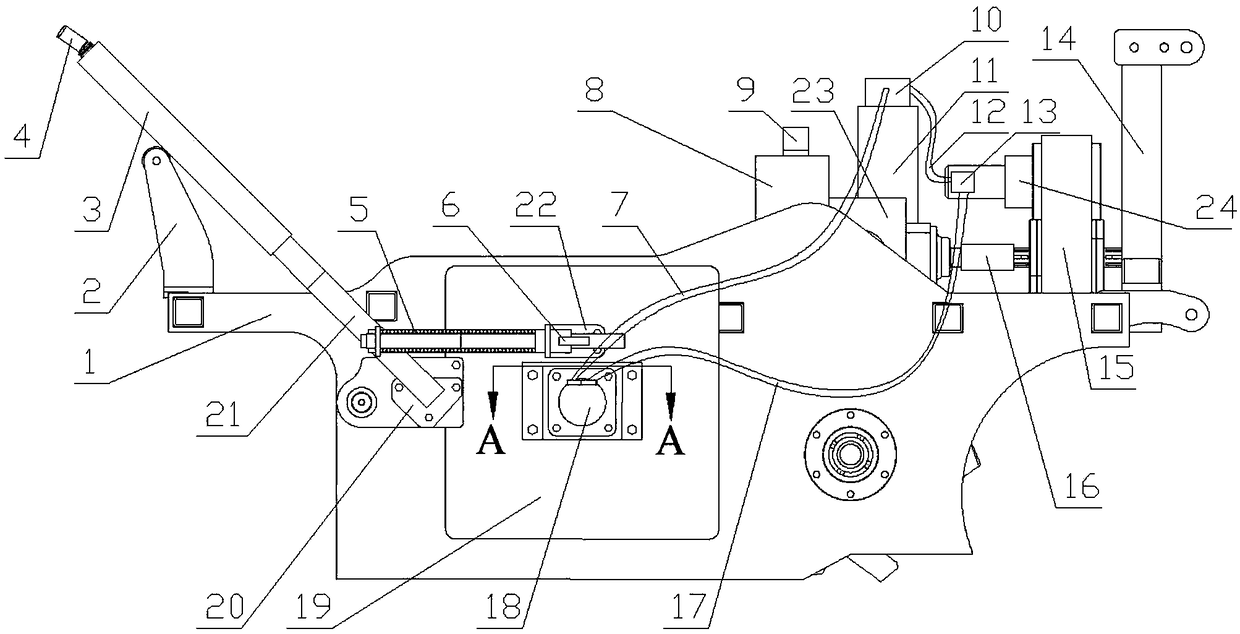

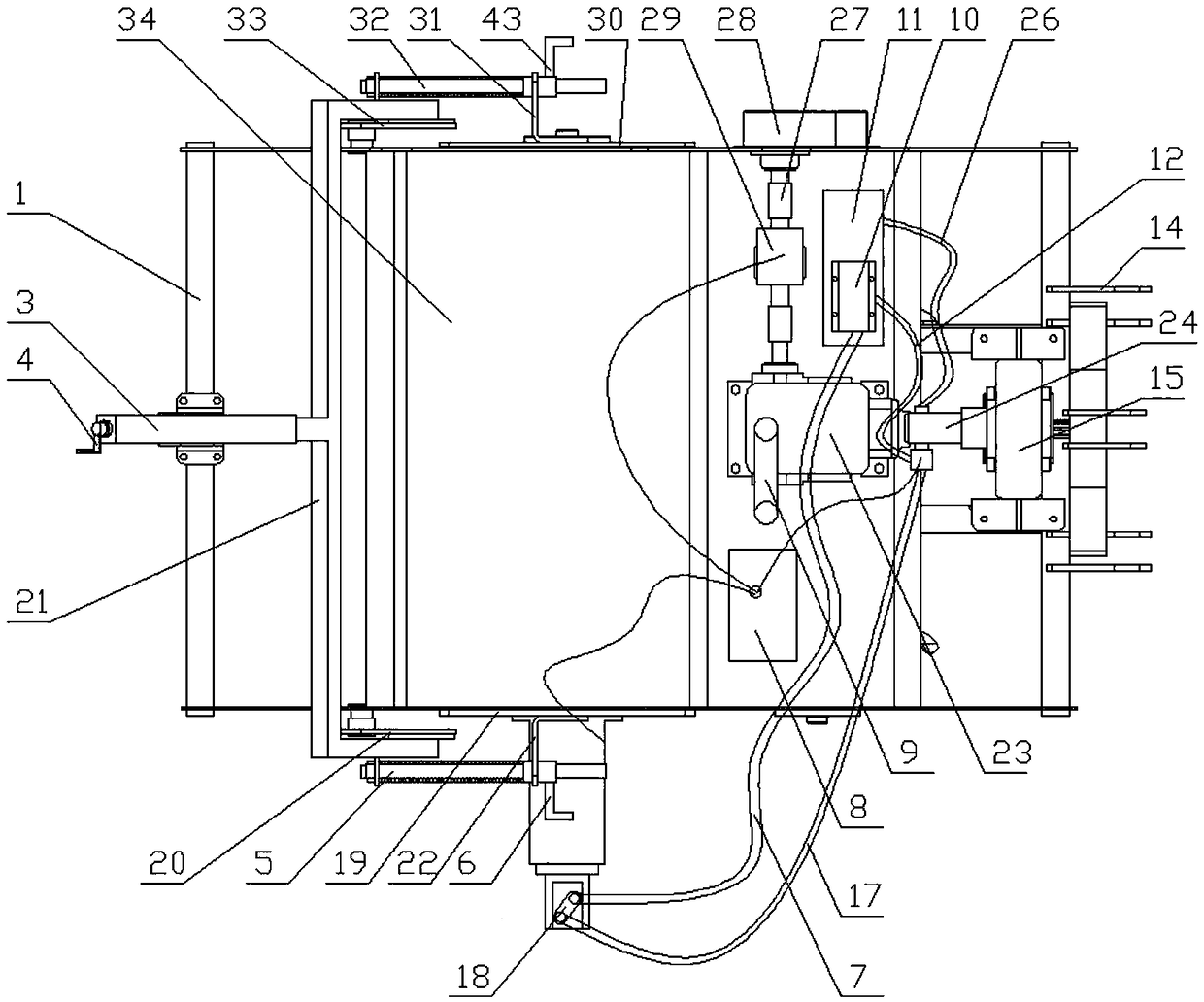

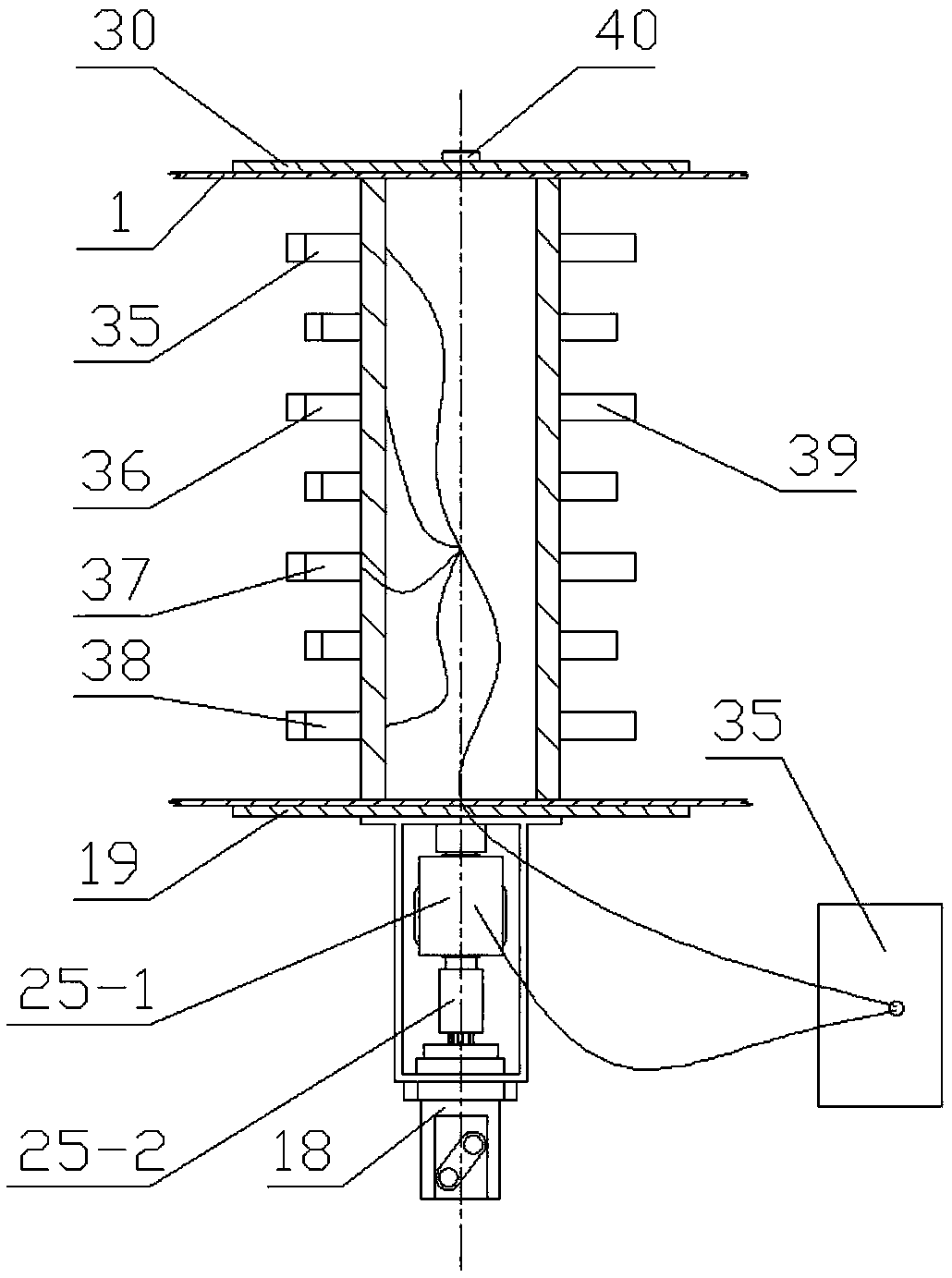

[0032] The soil layered rotary tillage test device of the present embodiment, such as Figure 1-3 with Image 6 As shown, including rotary tiller roller speed adjustment device, soil crushing knife roller speed adjustment device and soil crushing knife roller position adjustment device, rotary tiller roller speed adjustment device, soil crushing knife roller speed adjustment device and soil crushing knife roller position adjustment The devices are installed on rack 1.

[0033] Rotary cultivator roll rotation speed regulating device includes speed-increasing gear box 15, multi-speed gearbox 23, side gear box 28, rotary tiller roll 42 and some rotary blades installed on rotary tiller roll 42. In this embodiment, the soil layered rotary tillage test device is hooked on the tractor through the three-point suspension bracket 14, and the input shaft of the speed-increasing gearbox 15 is connected with the output shaft of the PTO of the tractor to receive power. This embodiment ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com