Rubber pipe forming auxiliary device and rubber pipe forming auxiliary technology and application thereof

An auxiliary device and forming process technology, which is applied in the field of rubber hose forming auxiliary devices, can solve the problems of inconsistent wall thickness of rubber hose, deviation of wall thickness of tube blank, low efficiency, etc., and achieve the effect of improving efficiency, reducing difficulty, and reducing time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

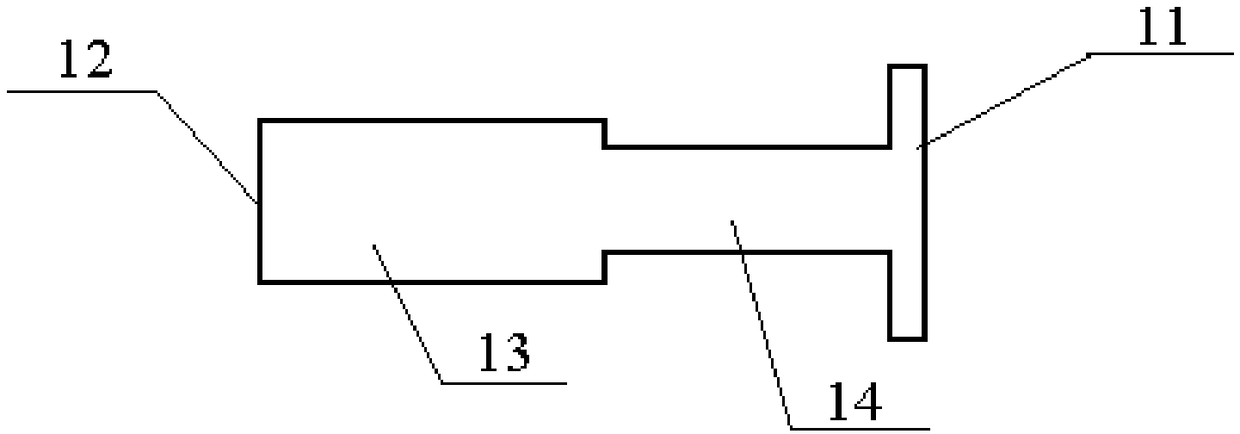

[0030] according to figure 1 The hose forming aid shown preforms the hose and completes the hose forming process. figure 1 The shown rubber hose forming auxiliary device includes a fixed end 11 and a sleeve end 12, at least a part of the auxiliary device is configured as a rubber hose diameter expansion part 13, and the rubber hose diameter expansion part 13 is arranged from the sleeve end 12 to the fixed end 11 on the path of

[0031] The end surface of the rubber hose expansion part 13 coincides with the sleeve end 12, and the other part of the auxiliary device close to the fixed end 11 is set as a non-hose expansion part 14, and the rubber hose expansion part 13 is only provided with an expansion end.

[0032] According to the following steps, the tube blank is subjected to the molding process to obtain the rubber tubes of the various embodiments.

[0033] 1) Set the tube blank of the rubber hose on figure 1 The rubber hose expansion part of the rubber hose forming auxil...

Embodiment approach 2

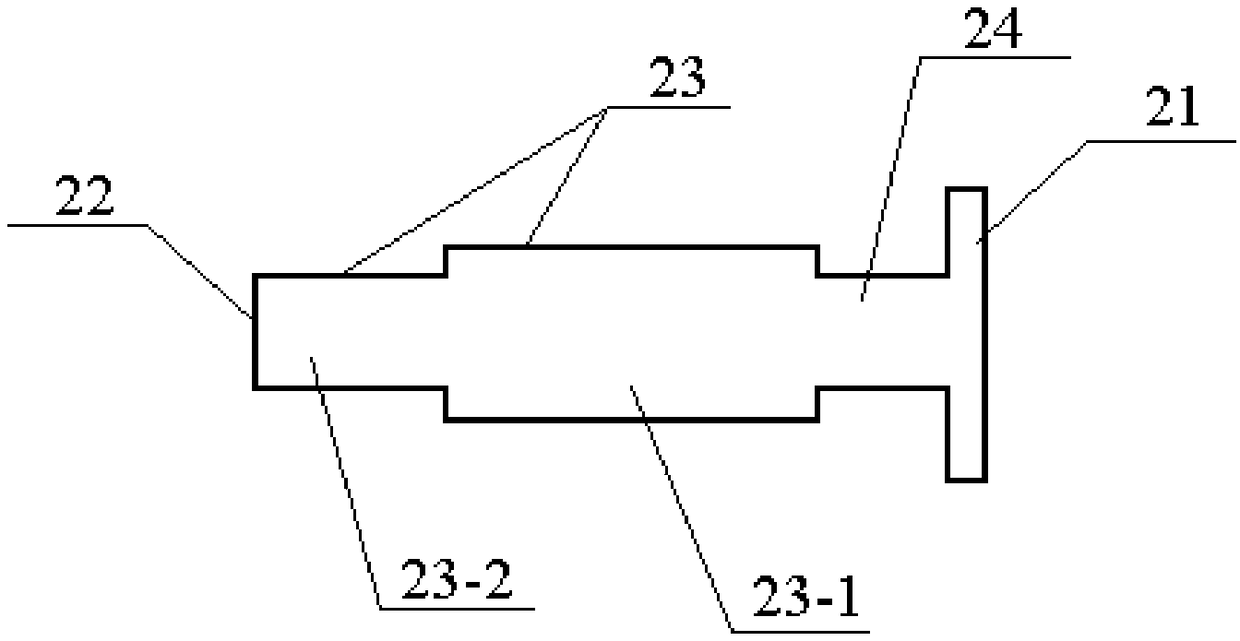

[0039] according to figure 2 The hose forming aid shown preforms the hose and completes the hose forming process. figure 2 The shown rubber hose forming auxiliary device includes a fixed end 21 and a sleeve end 22, at least a part of the auxiliary device is configured as a rubber hose diameter expansion part 23, and the rubber hose diameter expansion part 23 is arranged from the sleeve end 22 to the fixed end 21 on the path of

[0040] The end surface of the hose expanding part 23 coincides with the sleeve end 22, and the other part of the auxiliary device close to the fixed end 21 is set as a non-hose expanding part 24, and the rubber hose expanding part 23 is provided with a front end 23-2 and an expanding end 23-1, the outer diameter of the leading end 23-2 is smaller than the outer diameter of the enlarged diameter end 23-1.

[0041] According to the following steps, the tube blank is subjected to the molding process to obtain the rubber tubes of the various embodiment...

Embodiment approach 3

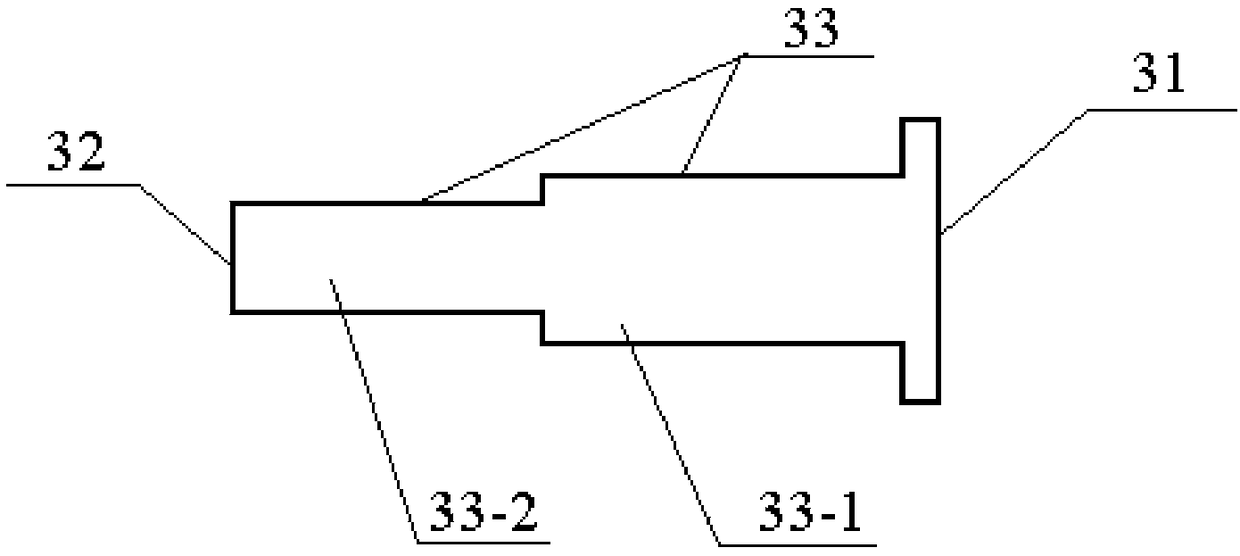

[0048] according to image 3 or Figure 4 The hose forming aid shown preforms the hose and completes the hose forming process. image 3 or Figure 4 The shown rubber hose forming auxiliary device includes a fixed end 31 and a sleeve end 32. At least a part of the auxiliary device is set as a rubber hose diameter expansion part 33, and the rubber hose diameter expansion part 33 is arranged from the sleeve end 32 to the fixed end 31. on the path of

[0049] The diameter-expanding portion 33 of the rubber hose includes a leading end 33-2 and an expanding end 33-1, the end face of the leading end 33-2 coincides with the sleeve end 32, and the end face of the expanding end 33-1 coincides with the fixed end 31 ; The outer diameter of the leading end 33-2 is smaller than the outer diameter of the enlarged diameter end 33-1.

[0050] According to the following steps, the tube blank is subjected to the molding process to obtain the rubber tubes of the various embodiments.

[0051]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com