Novel pressure head mechanism with floating fine adjustment function

An indenter, a new type of technology, applied in the field of appliances, can solve problems such as the inability to meet economical and efficient production requirements, and achieve the effect of saving time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

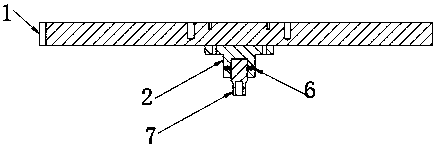

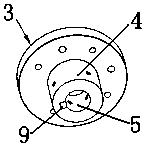

[0012] Combine below Figure 1 to Figure 4 Specific description embodiment:

[0013] The floating pressure head mechanism for quick-change pressing includes a guide plate 1, and the pressure head flange 2 is arranged on the guide plate 1. The pressure head flange 2 includes a flange base 3 and a pressure head seat 4. The flange base of the flange base is fixedly arranged on the guide plate, and the pressure head seat is provided with a pressure head placement groove 5, and a plurality of ball plungers 6 are arranged on the inner wall of the pressure head seat, and a pressure head placement groove is provided with a pressure head. The head 7, the indenter includes a front end and a tail end, and an annular groove 8 is opened at the tail end at a height of one-third of the bottom, and the front end and the tail end are connected by a stepped slope 10; the ball head column When the plug is arranged in the annular groove, the pressure head is floatingly arranged on the pressure h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com