Asphalt adhesive layer spreading device for annular-road curved surfaces and method

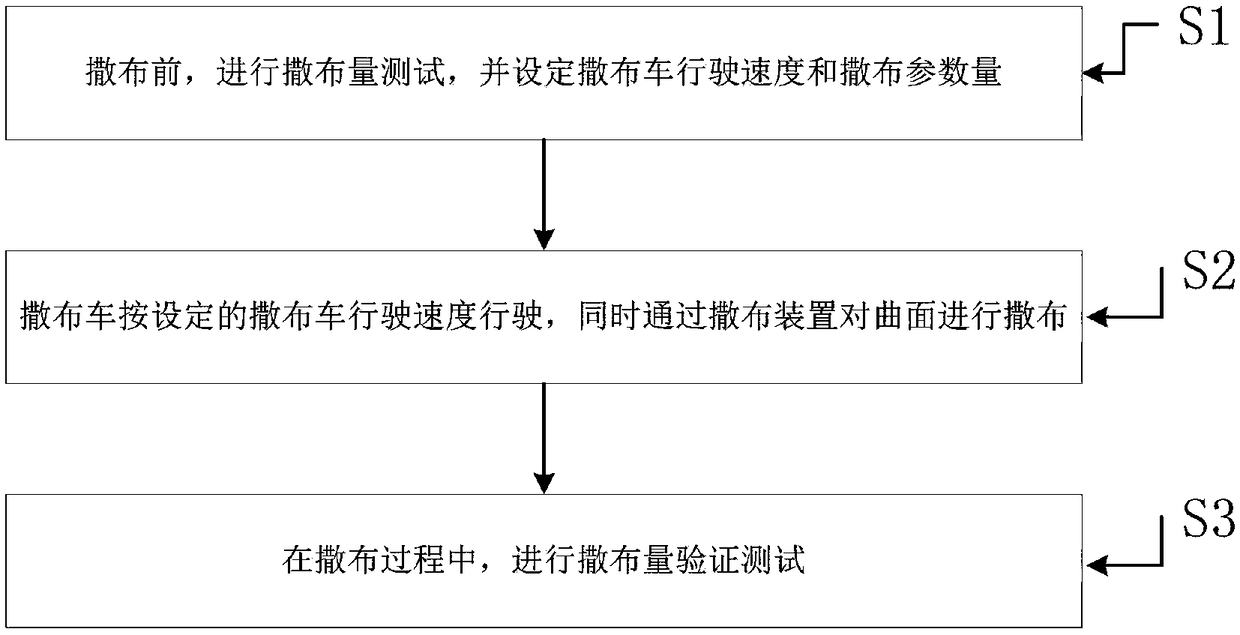

A technology of spreading device and asphalt sticky layer, applied in the field of asphalt sticky layer spreading device, can solve the problems of inability to spread quality inspection, adhesion of asphalt layer to layer, and inability to spread, etc., to achieve real results, small fluctuation, and ensure comprehensiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below, the technical solution of the present invention will be described in detail through specific examples.

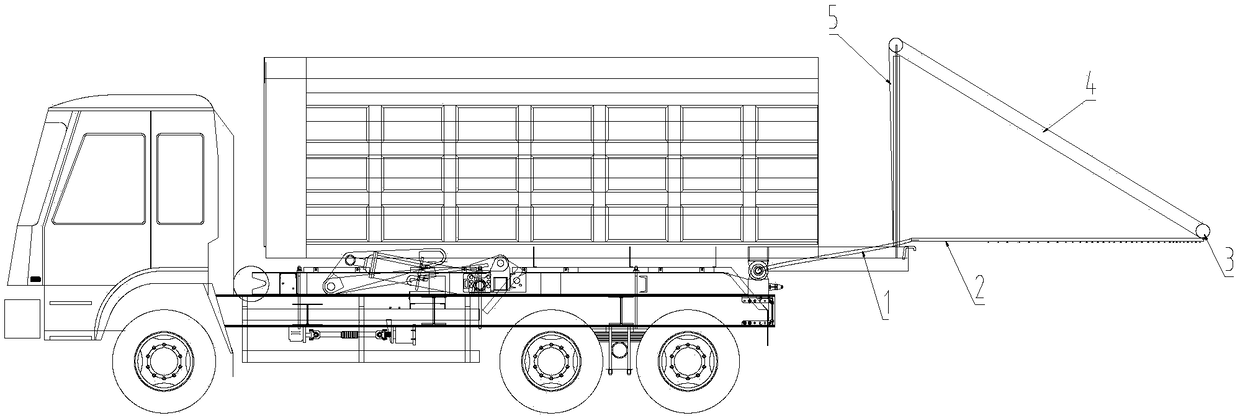

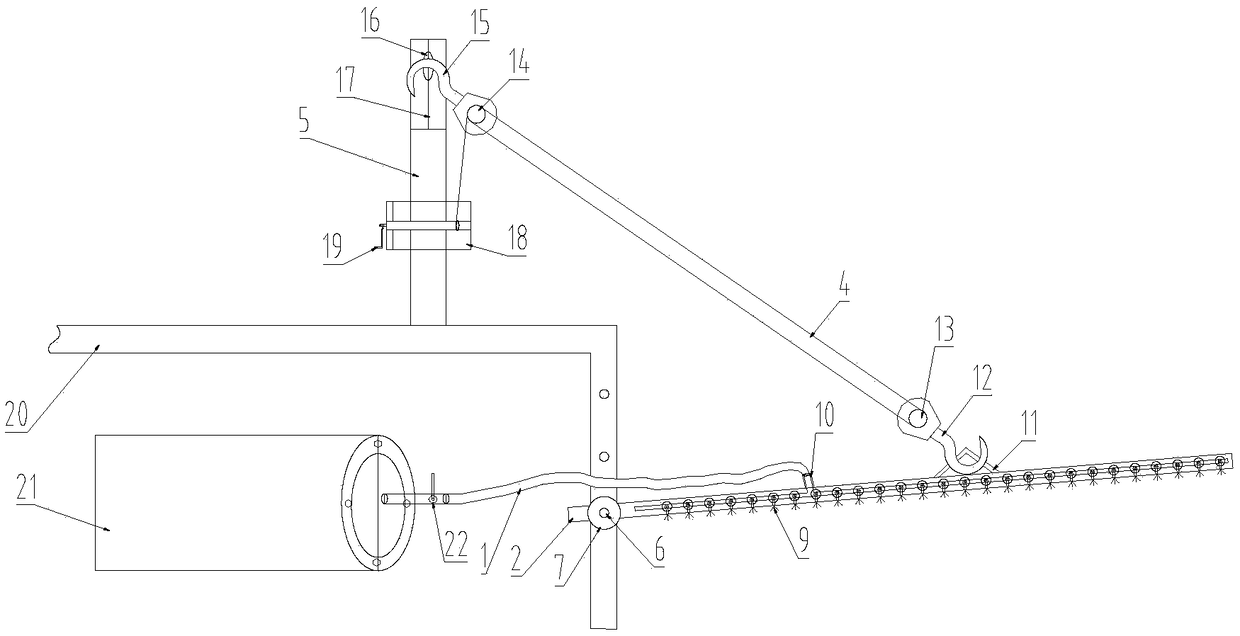

[0034] refer to figure 1 , a device and method for spreading an asphalt sticky layer on a curved surface of a ring track proposed by the present invention, comprising a spreading vehicle and an asphalt tank 21 arranged on the spreading vehicle, one side of the asphalt tank 21 is provided with a spreading device for evenly spreading the curved surface , and a spreading adjustment device for adjusting the spreading distance between the spreading device and the curved surface.

[0035] The spreading device includes a hose 1 and a steel pipe 2 communicating with the asphalt tank 21. The steel pipe 2 is connected with a round pipe on the outside in the axial direction. The end of the hose 1 away from the asphalt tank 21 is in sealing communication with the round pipe. At least one nozzle 9 corresponding to the position of the curved surface is communicated with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com