Detection device for hygroscopic property of vehicle coating welding seam sealant

A technology of moisture absorption performance and detection device, which is applied in the direction of measuring device, material inspection product, instrument, etc., can solve the problems of inability to produce and accurately reflect the moisture absorption performance of PVC weld sealant, so as to avoid foaming defects. The effect of risk, loss reduction, and improved sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

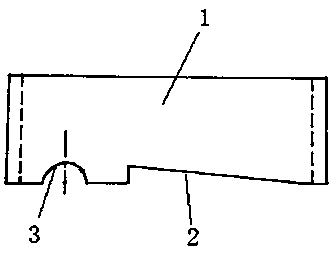

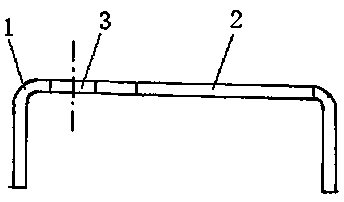

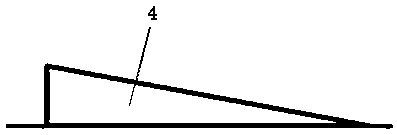

[0020] Please see attached figure 1 , attached image 3 and attached Figure 4 , a detection device for the hygroscopicity of a vehicle coating weld sealant, comprising a detection board 1 and a rubber strip production groove 2, the rubber strip production groove 2 is a wedge-shaped structure and is set at one side edge of the detection board 1, and the rubber strip The height range of the production groove 2 is 0-4mm, and the thickness of the rubber strip production groove 2 gradually increases, which can cover different thickness ranges of the rubber strips in the actual detection. The length of the rubber strip production groove 2 is 50-70mm, preferably 60mm; 1 Carry out scraping treatment at the glueing place, so that the weld sealant forms a wedge-shaped rubber strip 4 in the strip production groove 2.

[0021] Please see attached fig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com