Mechanism used for producing hollow hemispheroid

A technology of hollow hemisphere and hemisphere, which is applied in the field of mechanism for producing hollow hemisphere, can solve the problem of high production cost and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

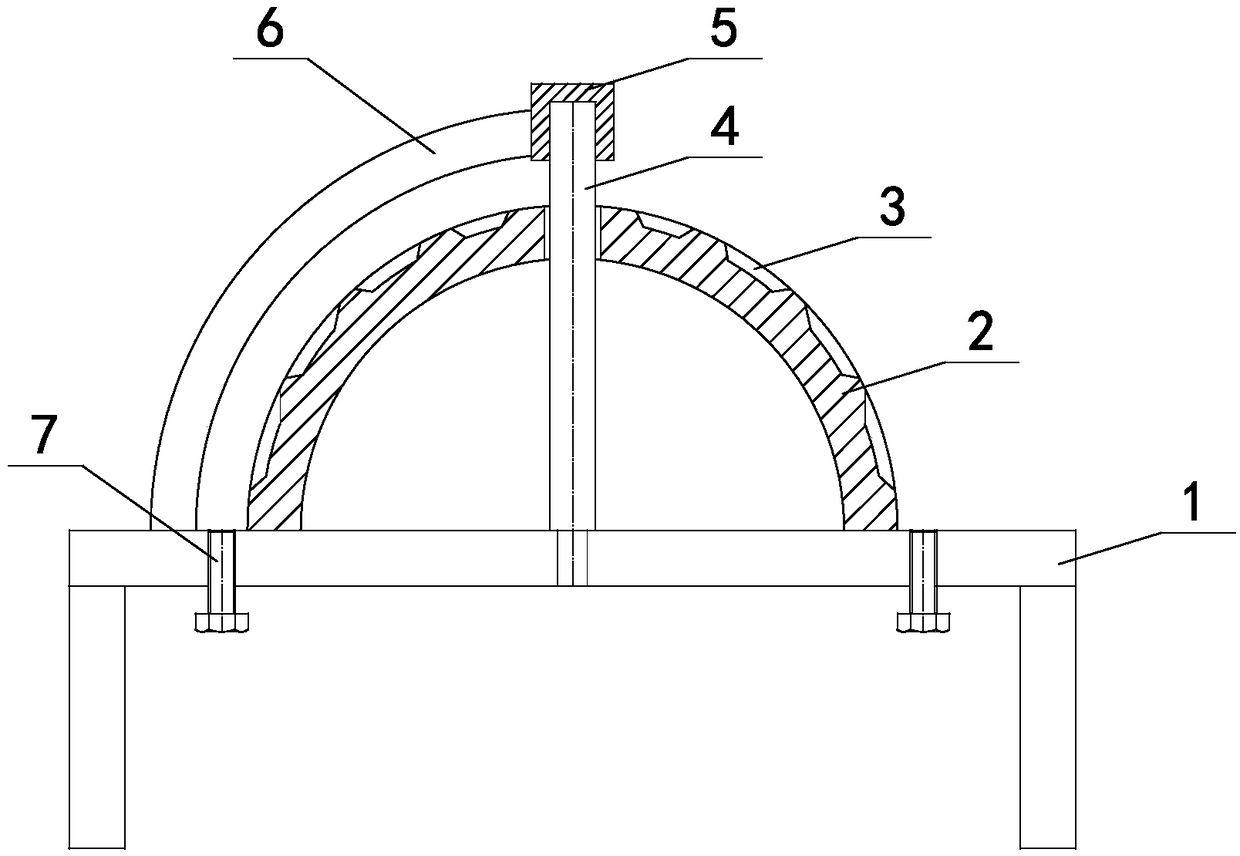

[0018] Such as figure 1 As shown, the described mechanism for producing hollow hemispheres includes a vertically arranged workbench 1, a hemispherical mold 2 is vertically arranged on the workbench 1, and a positioning device is installed vertically on the center of the hemispherical mold 2. Axle 4, the lower end of positioning shaft 4 is on the workbench 1, and the top of positioning shaft 4 is sleeved with cover 5, and the arc plate 6 that facilitates hemisphere molding is installed on the outer circle of cover cover 5.

[0019] In this embodiment, several grooves 3 are opened on the outer surface of the hemispherical mold 2 . The technical design of this section improves the adhesion of concrete.

[0020] The angle between the side surface of each groove 3 and the vertical direction is greater than 90 degrees. The technical design of this section facilitates the extraction of the solidified hemisphere from the hemispherical mold 2 .

[0021] Several screws 7 are installe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap