Plastic product residue cutting table

A technology of plastic products and cutting tables, which is applied in metal processing and other directions, can solve the problems of complex structure and inability to collect residual materials, and achieve the effect of easy rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

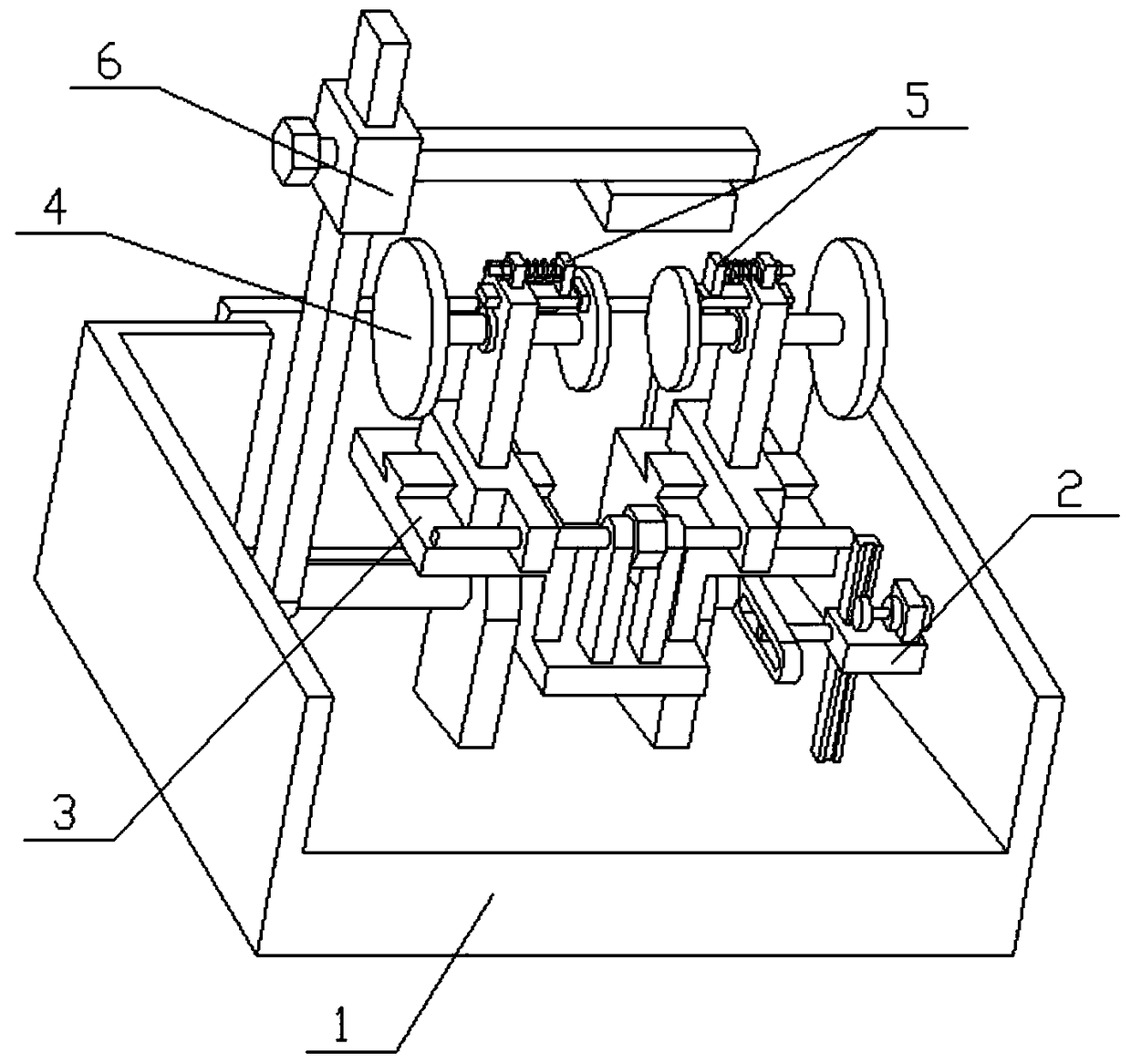

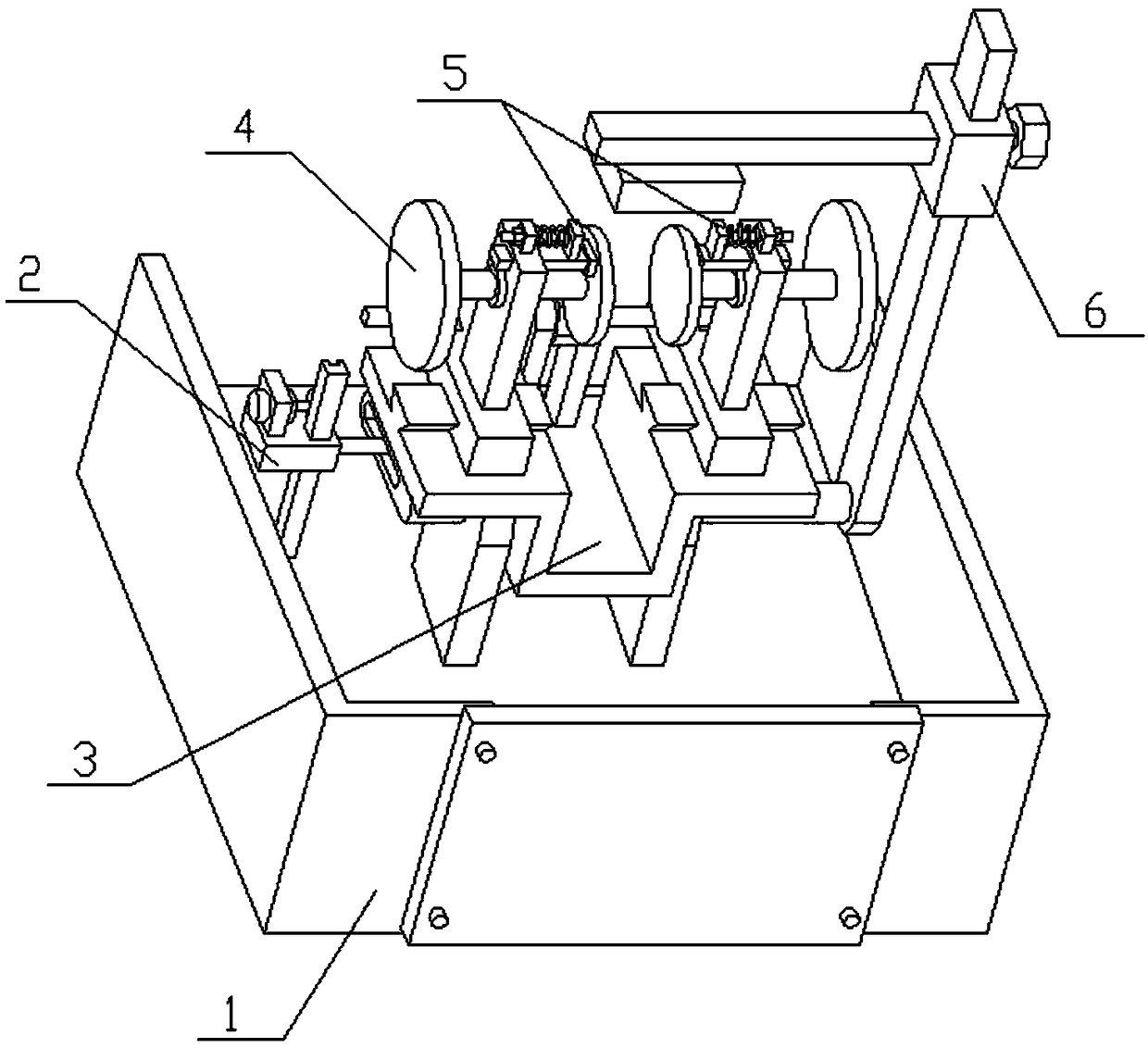

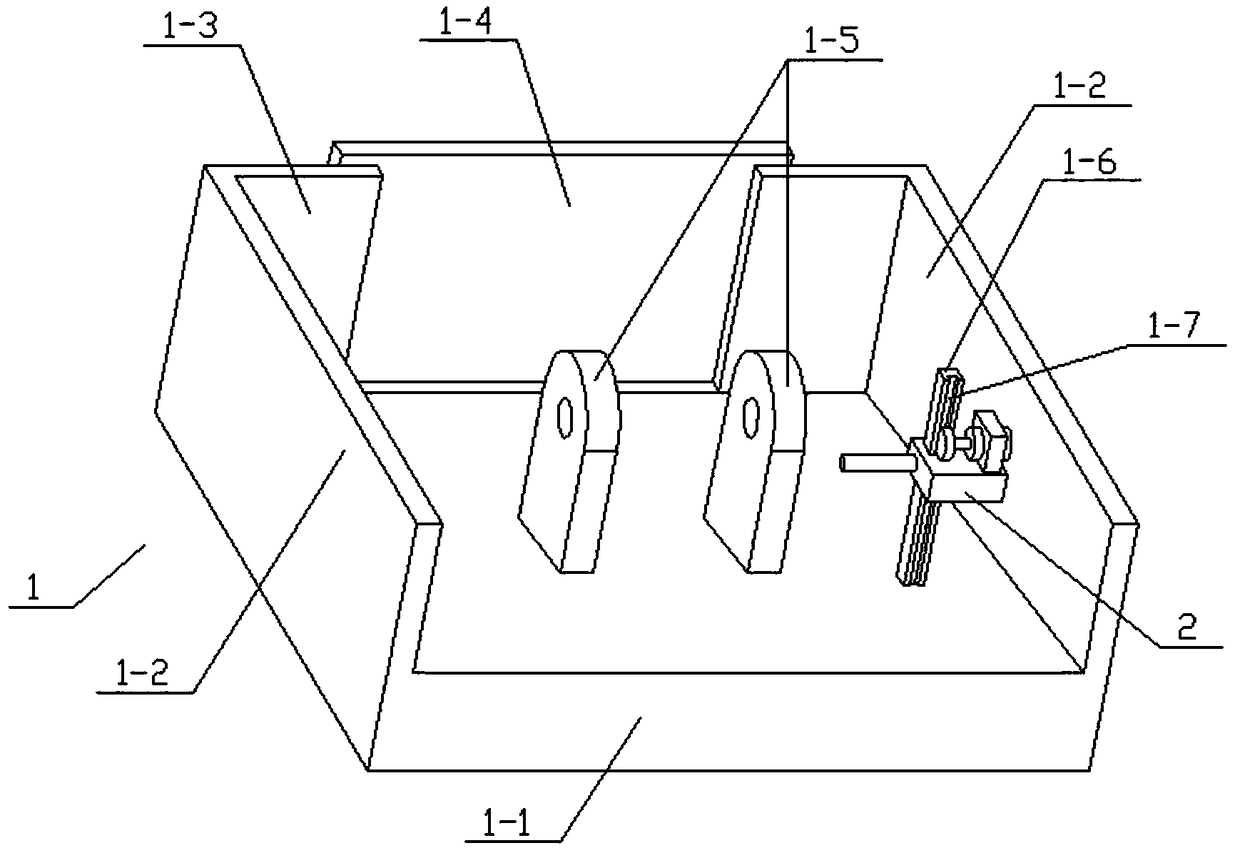

[0026] Combine below Figure 1-10 To illustrate this embodiment, the present invention relates to a cutting device, more specifically a cutting table for leftover plastic products, including a collection box 1, a slider assembly 2, a cutting table 3, a clamping frame 4, and a friction member 5 And the blowing assembly 6, the present invention is used for cutting the flash produced when the plastic blow molding product is made, and the present invention can clamp the plastic blow molding product of different sizes, and the plastic blow molding product after clamping can rotate the axis The axis of 4-5 is a shaft rotation, so as to facilitate the rotation of the plastic blow molding product and facilitate the manual cutting of different positions of the plastic blow molding product; the blowing component 6 can also blow the cut flash into the collection box 1 for collection; The cutting stand 3 can rotate around the axis of the left shaft 3-3, thereby turning the two clamping pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com