Buffering hinge with hinge cup arranged internally

A technology of hinge cups and hinges, which is applied in the field of hinges, can solve the problems of the easily damaged cylinder body of the damper, unreasonable design, inconvenient disassembly and assembly of the damper, etc., and achieve the effect of prolonging the service life and reducing contact damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

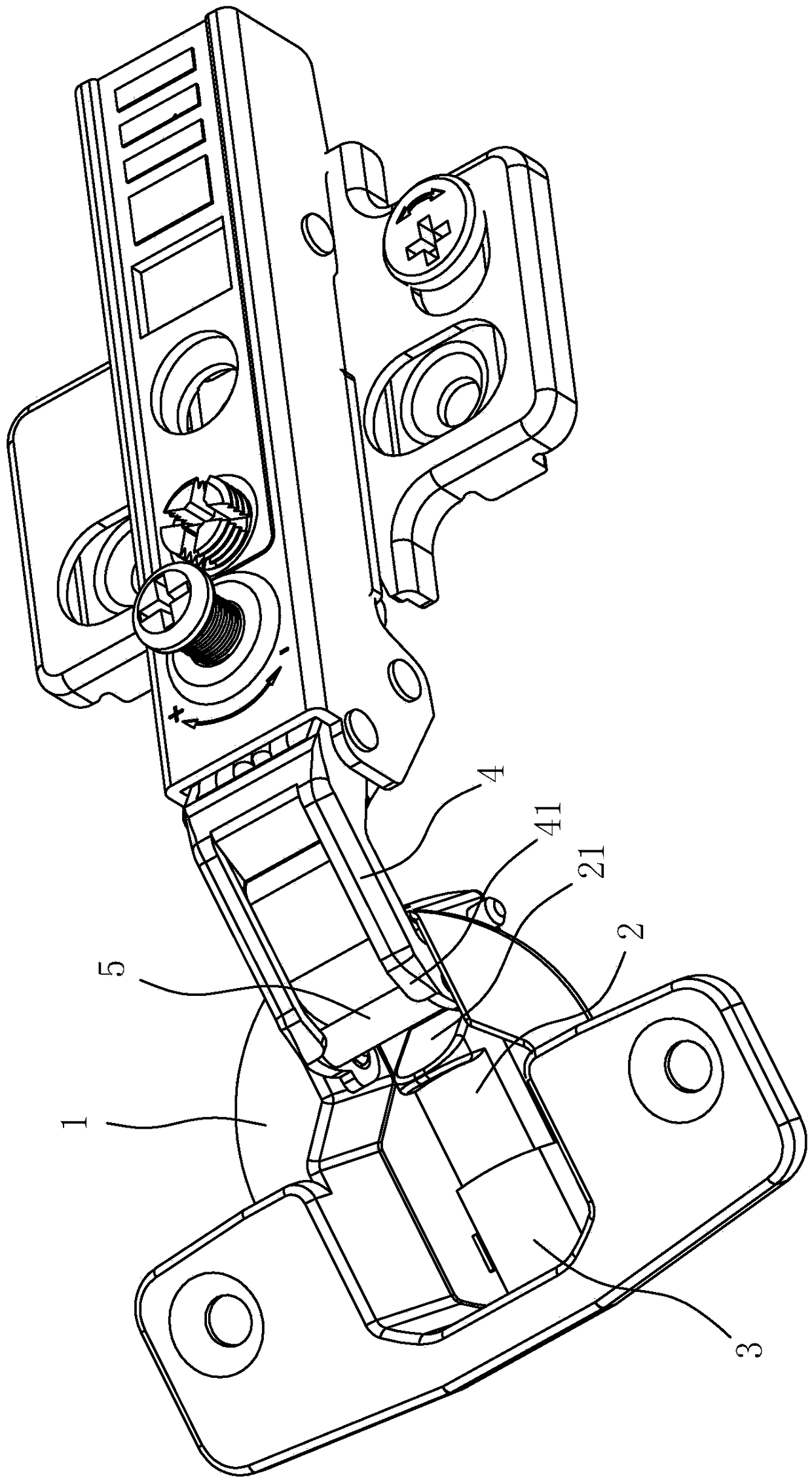

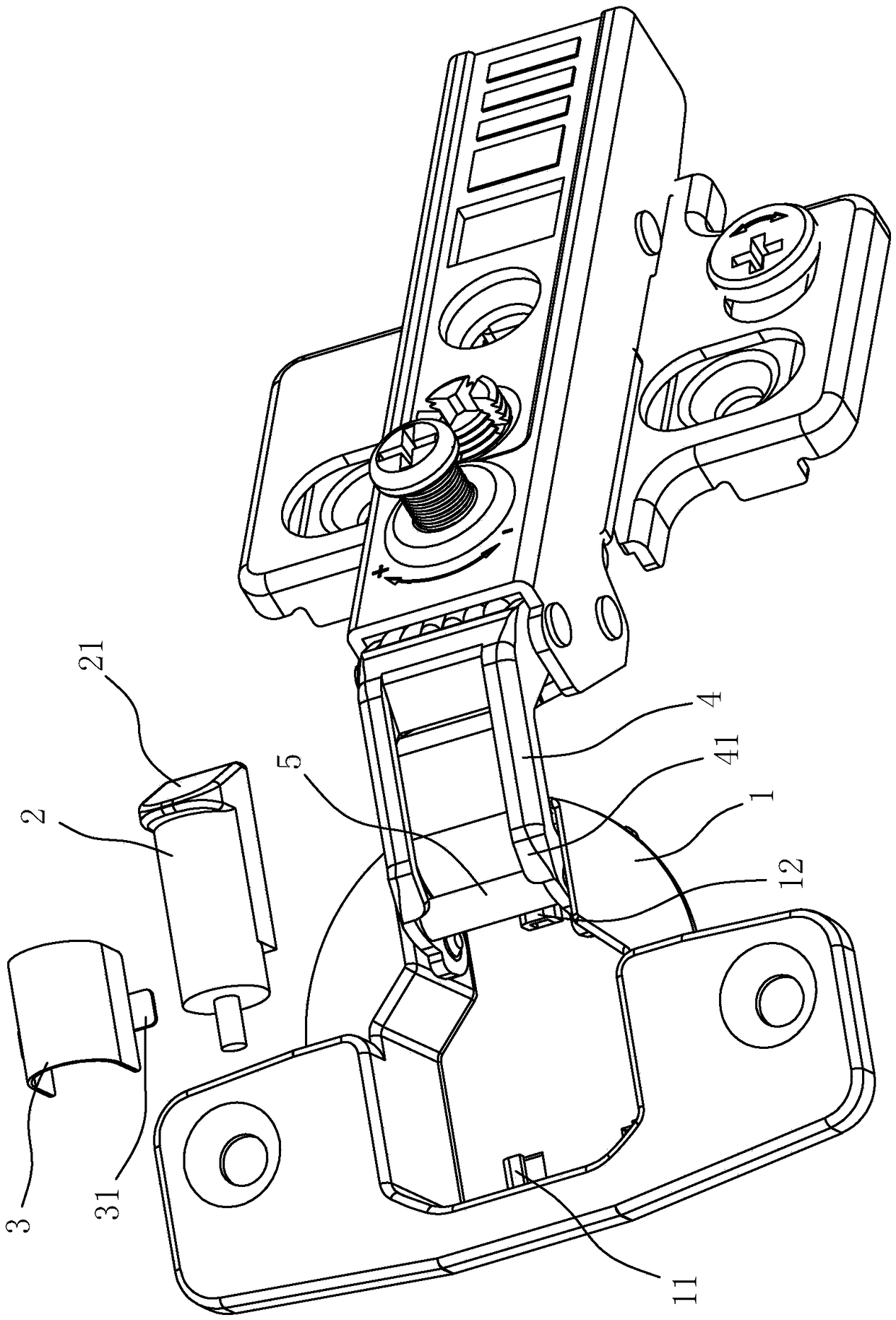

[0010] like figure 1 , 2 As shown, a buffer hinge with a built-in buffer hinge includes a buffer hinge. The damper 2 for the swing of the buffer hinge cup 1 is installed in the hinge cup 1 of the buffer hinge. The oil cylinder end of the damper 2 is set at the hinge end of the hinge cup 1. . In the present invention, a roller 5 is installed horizontally on the swing shoulder 41 of the link arm 4 hinged with the hinge cup 1, and the oil cylinder end of the damper 2 is formed with an inclined surface that abuts against the roller 5 when the hinge cup 1 closes and swings. twenty one.

[0011] When closing the door, the door panel drives the hinge cup 1 to swing, and when the power link arm swings past the dead point position of the four-bar linkage mechanism, the elastic force of the torsion spring will drive the power link arm to continue to swing, driving the hinge cup 1 to swing when the door is closed. During this process, the roller 5 following the swing will abut against...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com