Pill weighing device and method

A weighing device and pill technology, which is used in measuring devices, weighing, weighing equipment for materials with special properties/forms, etc. Effectiveness of accuracy, labor saving, preventing contamination of pills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

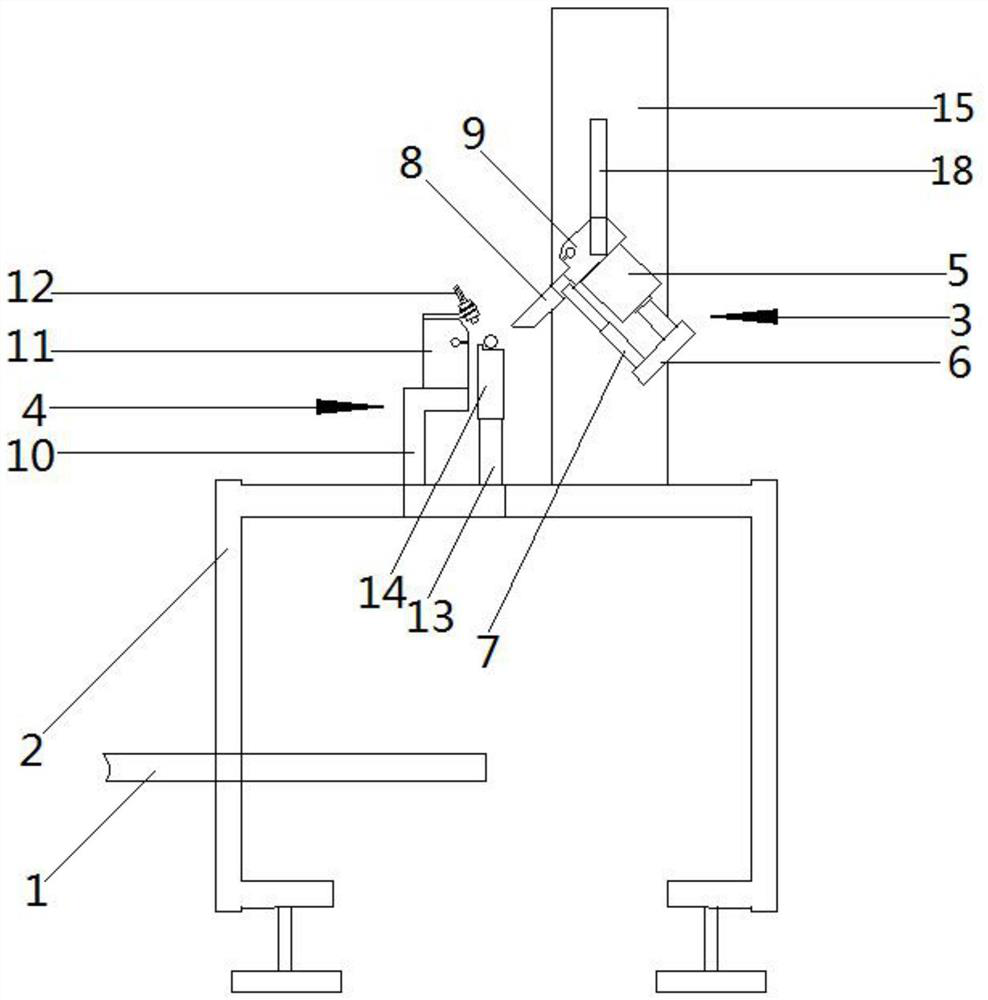

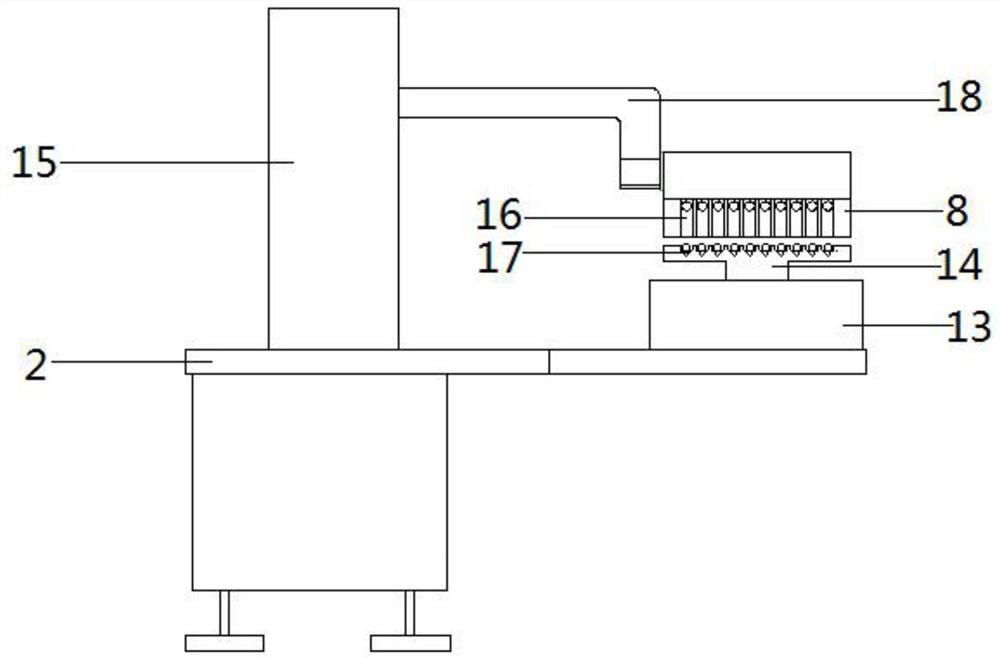

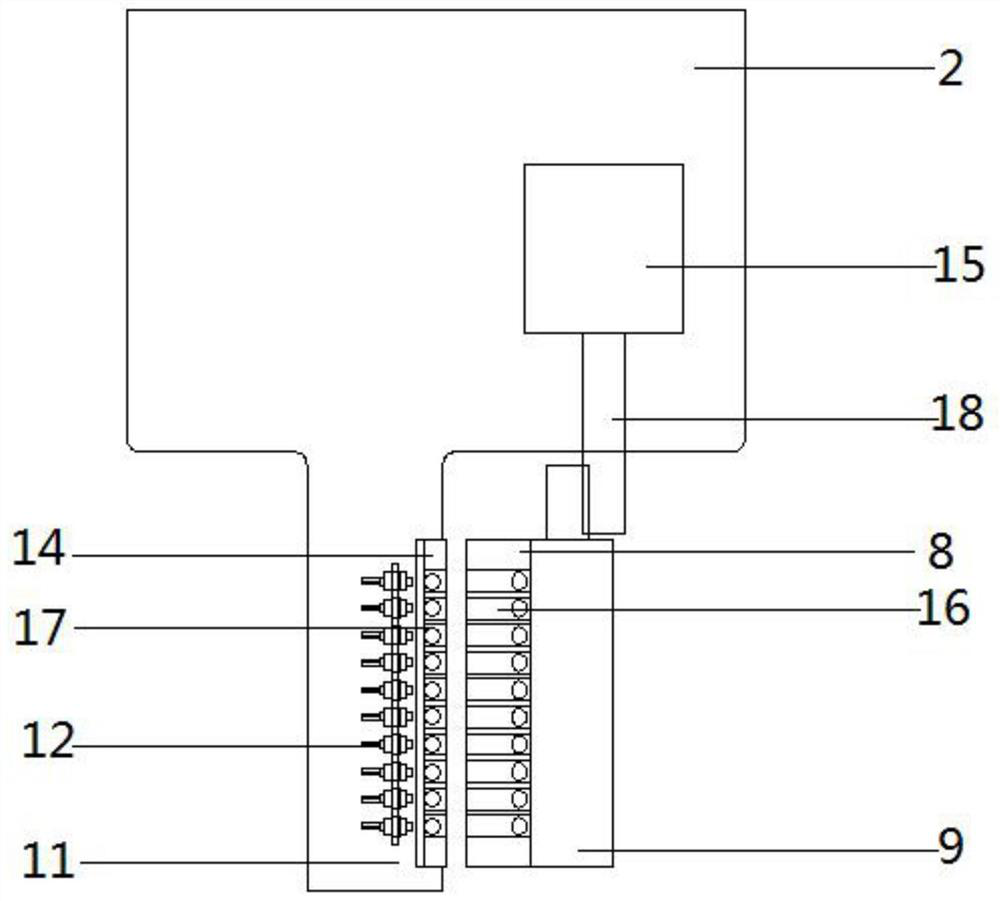

[0032] like Figure 1-Figure 3As shown, this embodiment provides a pill weighing device, which is mainly used for weighing with a pill making machine, and includes a receiving device 3, a moving element 15 and a weighing assembly 4, and the moving element 15 is used to drive the receiving device 3 The electric vibrating plate 1 close to the pill making machine is used to pick up the pills or the weighing component 4 is used to transport the pills. The receiving device 3 includes a receiving element 8 and a medicine discharging component. When the electric vibrating plate 1 is transported into the pill making machine, the receiving element 8 When receiving the pills, when it is close to the weighing component 4, the medicine discharging component pushes the pills out to the weighing component 4 for weighing, without manual grabbing, which reduces contact damage to the pills and saves labor. The upper surface of the receiving component 8 It is a receiving surface, and the receiv...

Embodiment 2

[0043] like Figure 4 As shown, this embodiment provides a method for weighing pills. Based on the pill weighing device provided in Embodiment 1, when weighing pills, the steps are as follows: a. In the initial state, the pills are transported from the pill making machine along the direction of the arrow The vibrating plate is transported out; b. The receiving device 3 is vertically lowered to the lowest position, that is, it is located under the conveying vibration plate of the pill making machine, and the pills fall into the through hole; c. The receiving device 3 rises to the middle position and pauses slightly. A blowing module 9 blows off the pills that are not in the through hole; d. The receiving device 3 rises to the highest position and pauses slightly, the ejector rod 7 pushes out the pills in the through hole, and the first blowing module 9 blows air; e The pills fall into the weighing tank 17 of the weighing pan 14, the load cell 13 starts to detect the weight of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com