A pressure-controlled slurry multi-point synchronous sampling device and method

A synchronous sampling, multi-site technology, applied in sampling devices, sampling, measuring devices, etc., can solve the problems of difficult to meet the implementation conditions, and achieve the effect of flexible sampling, guaranteed stability, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

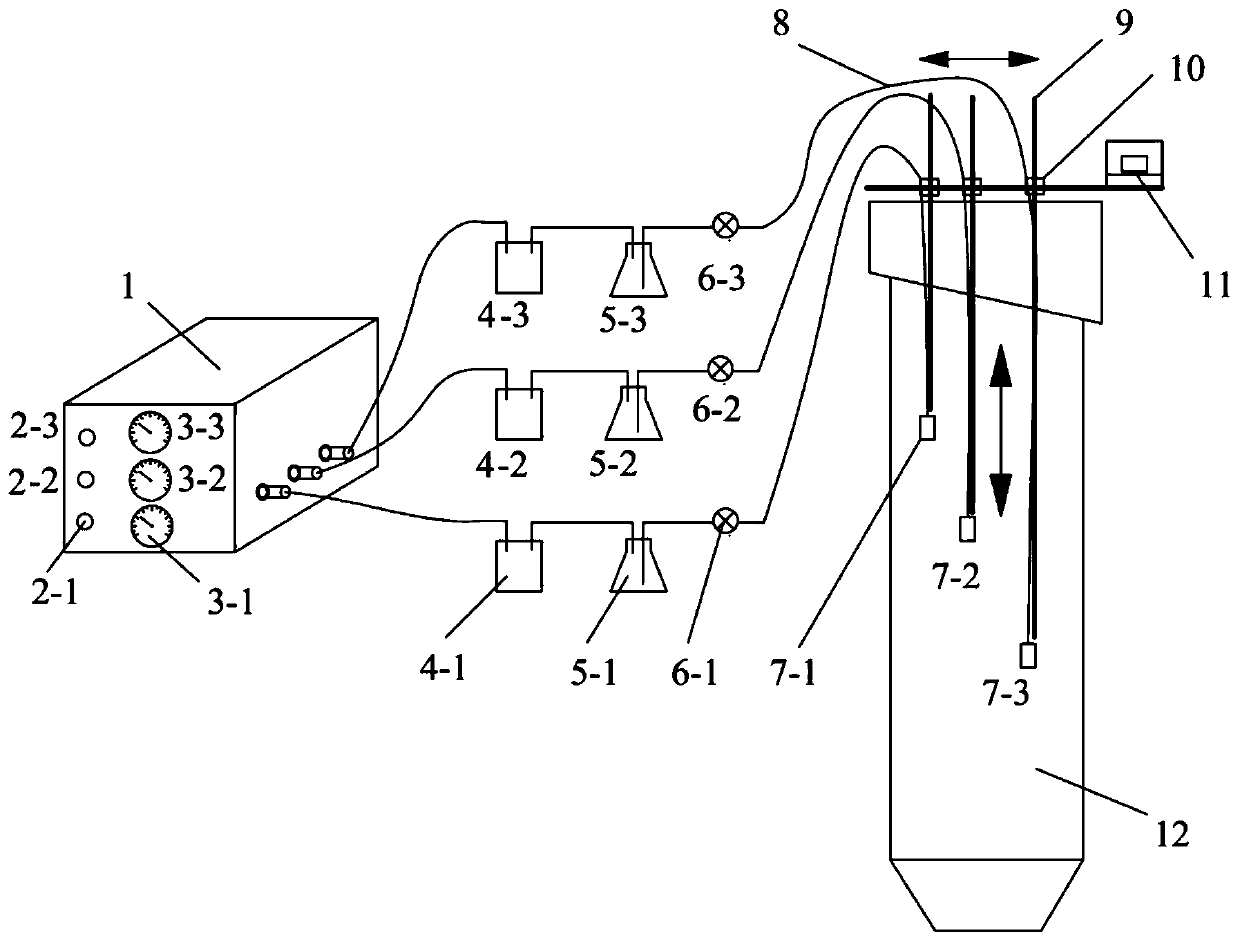

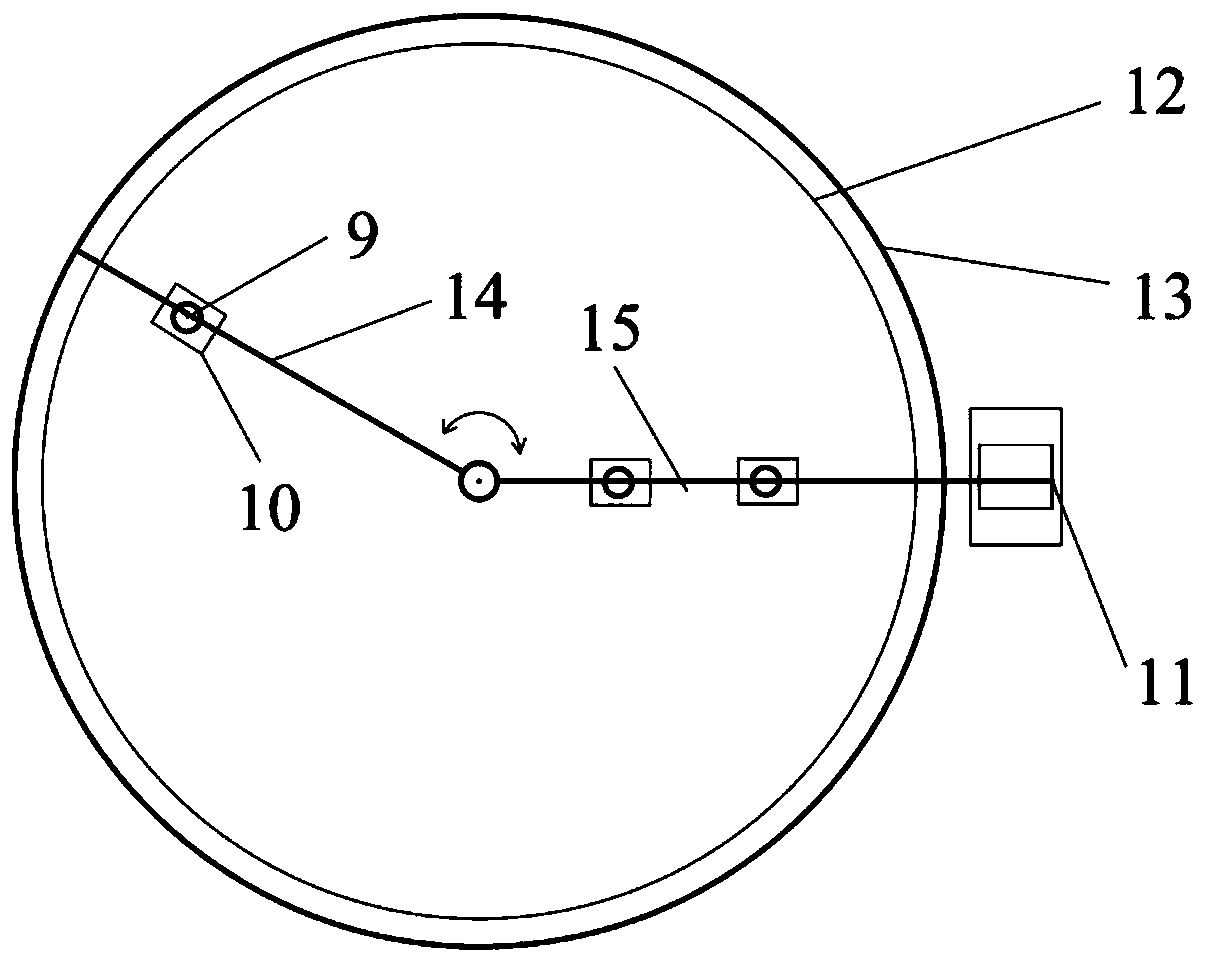

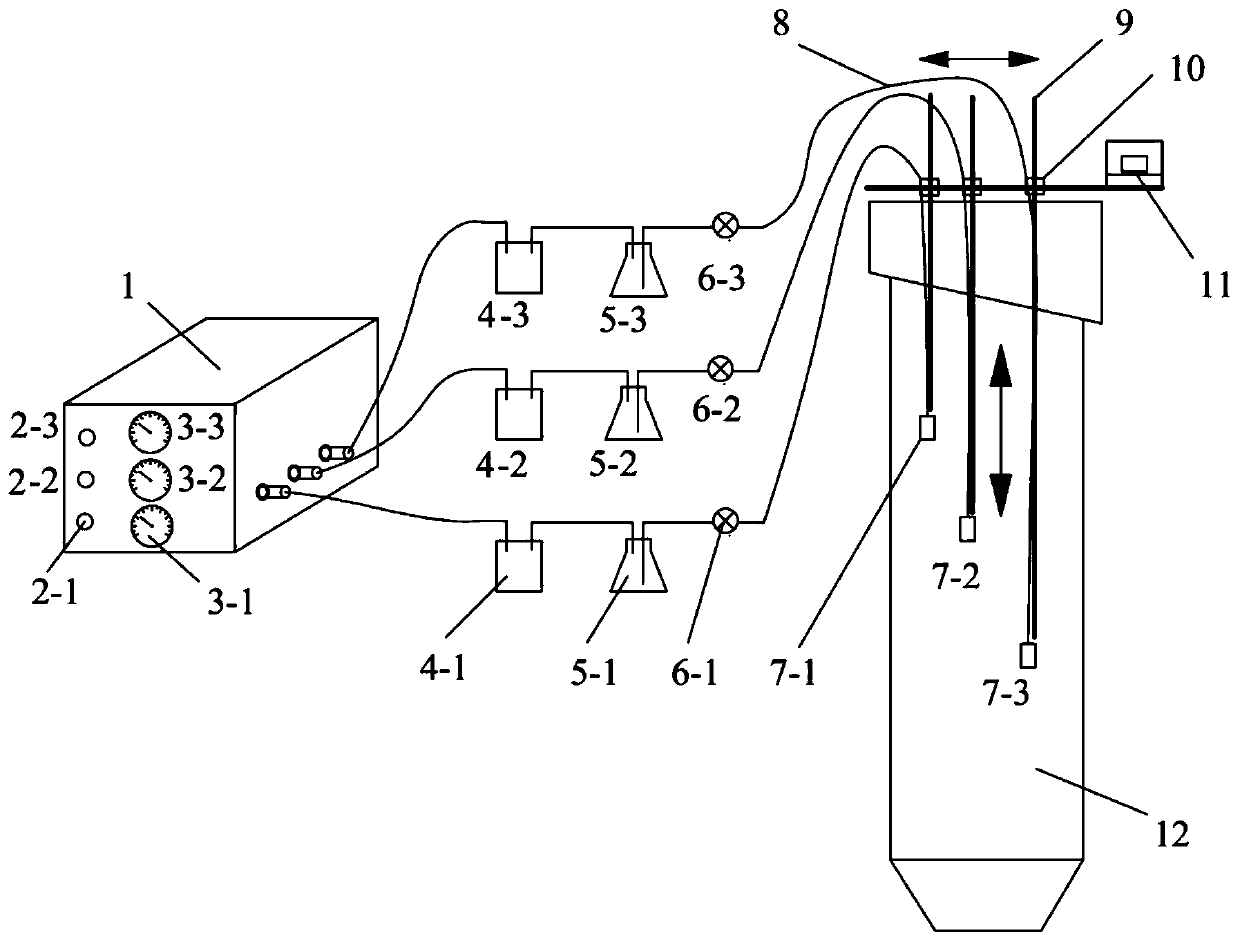

[0030] A pressure-controlling multi-point synchronous sampling device for pulp, including a plurality of (three in this embodiment example) parallel sampling unit systems, each sampling unit system is connected to the air compressor 1, and the air compressor 1 uses The pressure adjustment key is used to independently control the pressure of each sampling unit system, and the anti-slurry tank, the sample pot, the slurry control valve and the piston valve are connected in sequence through the pipeline. The piston valve is located in the flotation column 12 and is located between the piston valve and the sample. The pipeline between the kettles is the slurry s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com