Total cadmium analysis method

An analysis method and technology of an analysis device, which are applied in the direction of analysis by chemical reaction of materials, and material analysis by observing the influence on chemical indicators, etc., can solve the problems of absorbance fluctuation range, difficult disposal of waste liquid, strong toxicity, etc. , to achieve the effect of stable analysis results, simple waterway and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

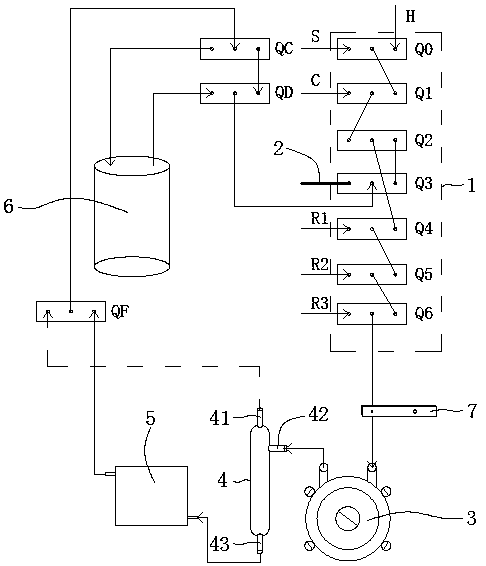

[0022] like figure 1 As shown, a new total cadmium analysis method is analyzed by using a total cadmium analysis device. The total cadmium analysis device includes a sampling line 1, a waste liquid tube 2, a peristaltic pump 3, a mixing tube 4, a colorimetric cell 5, and a high-temperature heating Device 6, water sample detector 7 and three-way valves QC, QD and QF. The side of the mixing tube 4 is provided with a side liquid inlet 41 , the top is provided with a top liquid outlet 42 , and the bottom is provided with a bottom liquid outlet 43 , and the side liquid inlet 41 is connected with the peristaltic pump 3 . One end of the colorimetric cell 5 is connected to the bottom liquid outlet 43, the other end is connected to the normally open end of the QF, the top liquid outlet of the mixing tube 4 is connected to the normally closed end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com