Mold for extrusion formation of equal-thickness in-plane bent plate

A technology of extrusion molding and inner bending, which is applied in the direction of metal extrusion dies, etc., can solve the problems of easy wrinkling of the inner ring, shortened service life of the in-plane bending plate, and thinning of the thickness of the outer ring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

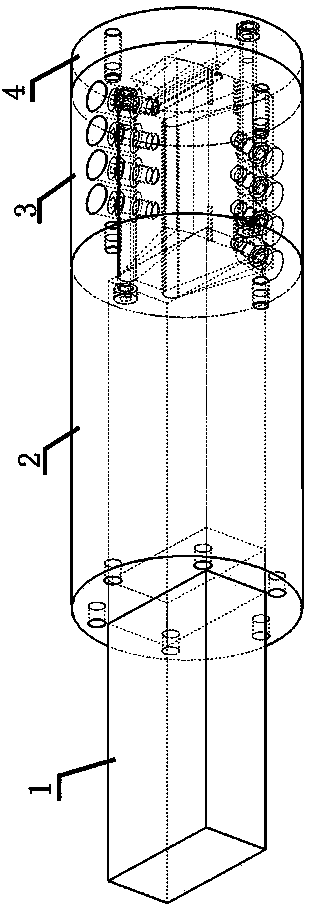

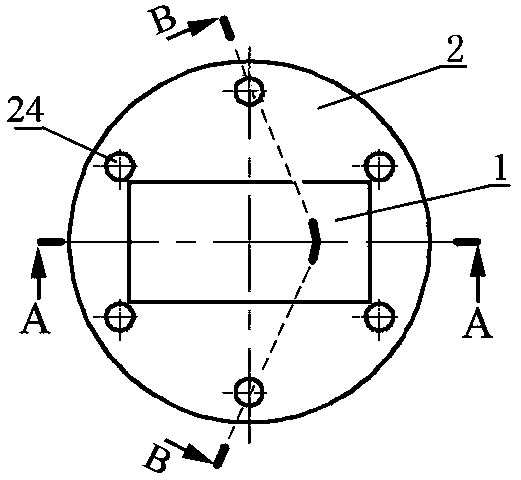

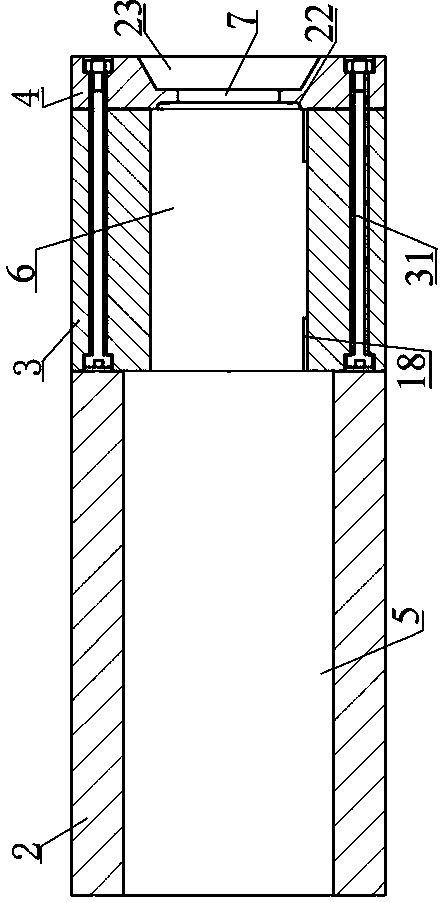

[0061] Referring to the accompanying drawings, the specific implementation is as follows:

[0062] The invention provides a mold for extrusion molding of inner curved plates of equal thickness. The mold is connected and installed with the existing extruder and used in conjunction with the cuboid extrusion rod 1 of the extruder. The extrusion direction of the extrusion rod 1 runs through the provided inner cavity, so that the blank whose original shape is a cuboid is extruded from the inner cavity of the mold by the extrusion rod 1 and extruded into an inner curved plate of equal thickness;

[0063] The extrusion machine adopts a 500T horizontal extrusion machine. The length of the extrusion rod 1 is 450mm. 220mm, the cross-sectional size of the blank on a plane perpendicular to the extrusion direction of the extrusion rod 1 is 69mm×49mm, and 6063 aluminum alloy is selected as the material of the blank;

[0064] The mold is divided into three sections, including the extrusion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com