A remote temperature measurement method for materials

A long-range, temperature-measuring probe technology, applied in the field of material processing, can solve the problems of coarse grain structure, the inability to accurately measure the temperature of profiles at the exit of the mold, the mechanical properties of the head and tail structures, and the uneven performance of shape, position and size, etc. The effect of temperature measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

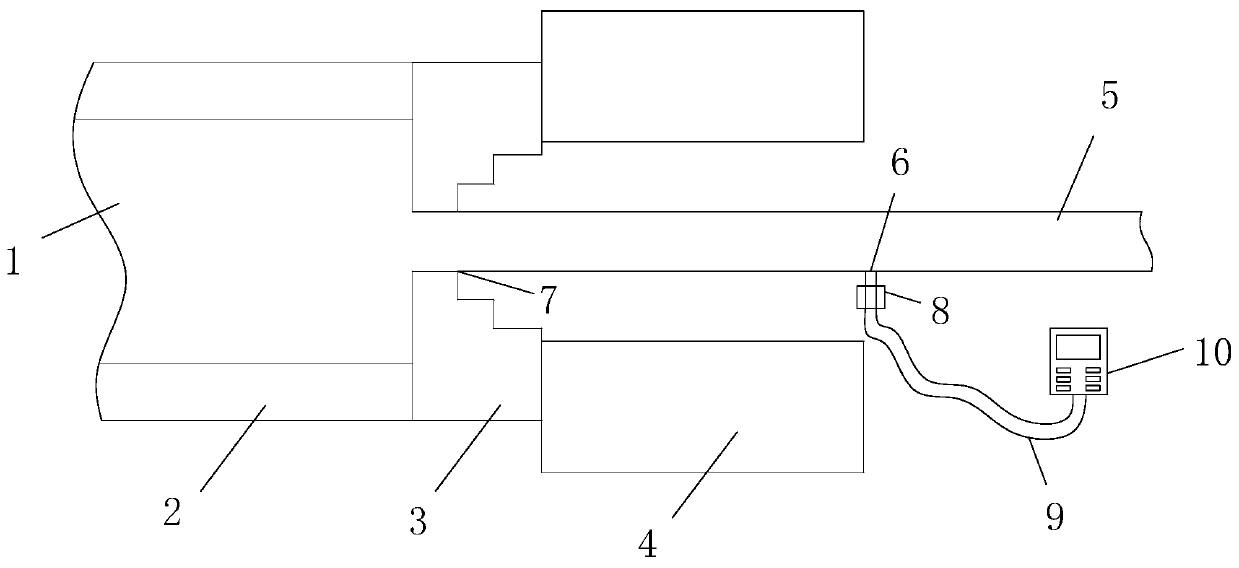

[0028] A method for remote temperature measurement of materials, comprising the steps of:

[0029] S1. Measure the temperature of the material at A, and the temperature change within time t is ΔT;

[0030] S2. Set according to the heat calculation formula: the heat Q released by the material 1 =CmΔT, where C is the specific heat capacity of the material, m is the mass of the material;

[0031] S3. Set according to Newton’s law of cooling: the heat q=hS(T A –T 介 ), where h is the surface heat transfer coefficient of the material, S is the surface area of the material, T A is the original temperature of the material at A, T 介 is the temperature of the surrounding environment medium; the heat Q dissipated by convection heat transfer within time t 2 =qt=hS(T A –T 介 )t;

[0032] S4. Set according to the law of energy conservation: the heat Q released by the material 1 Equal to the heat Q of convective heat transfer between the surrounding environment medium and the surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com