Waterproof USB connector mother plug structure and manufacturing method therefor

A technology of a connector and a manufacturing method, which is applied in the direction of connection, the assembly/disassembly of the parts of the connecting device, and the contact piece, can solve the problems of many production steps, low production efficiency, and high cost, and achieves improved product strength and production. Efficiency, the effect of improving the waterproof level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

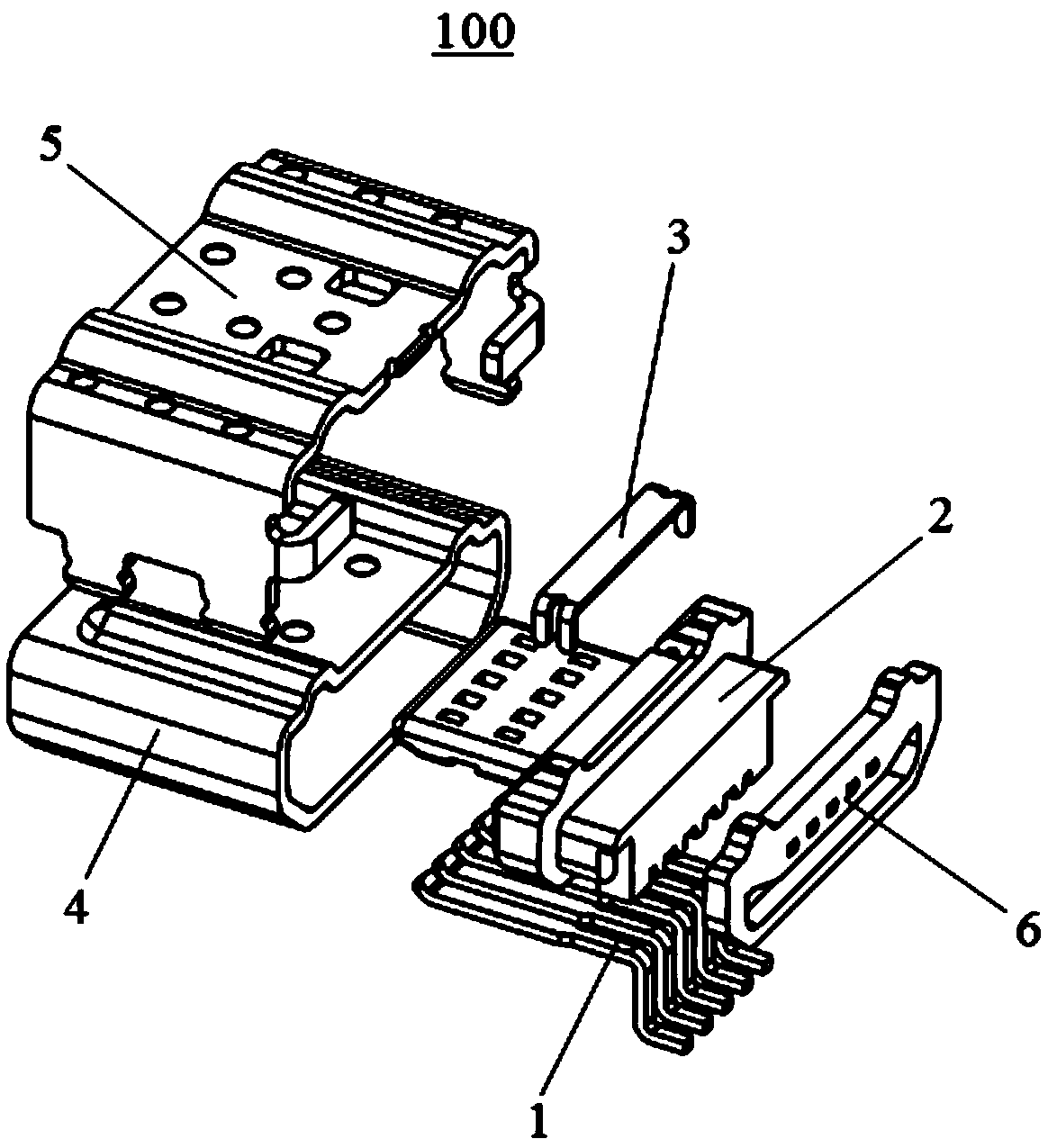

[0033] Please refer to Figure 1-Figure 7 , the present embodiment is a waterproof USB connector female plug structure 100, which includes a metal terminal 1, a plastic body 2 integrated with the metal terminal by injection molding, a fixed metal sheet 3 clamped on the upper surface of the plastic body 2, and a plastic The main metal shell 4 wrapped in the main body 2 without joints, the outer metal shell 5 wrapped on the outer surface of the main metal shell 4, and one end surface of the main metal shell 4 is sealed and filled in the plastic body 2 The colloid 6 in the gap between the main metal shell 4 and the outer metal shell 5 is welded, and the main metal shell 4 is fixedly connected to the plastic body 2 by welding with the fixed metal sheet 3 .

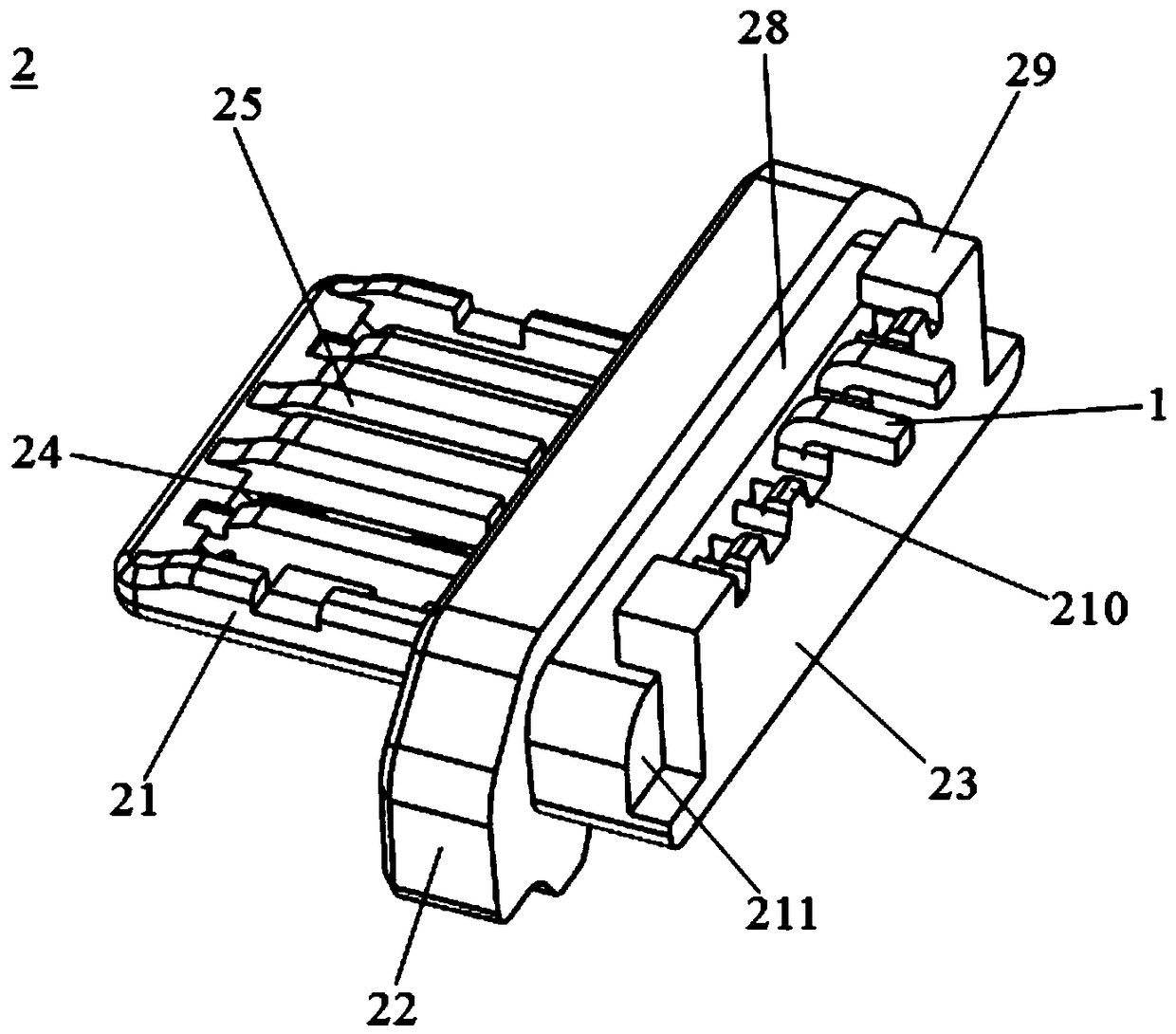

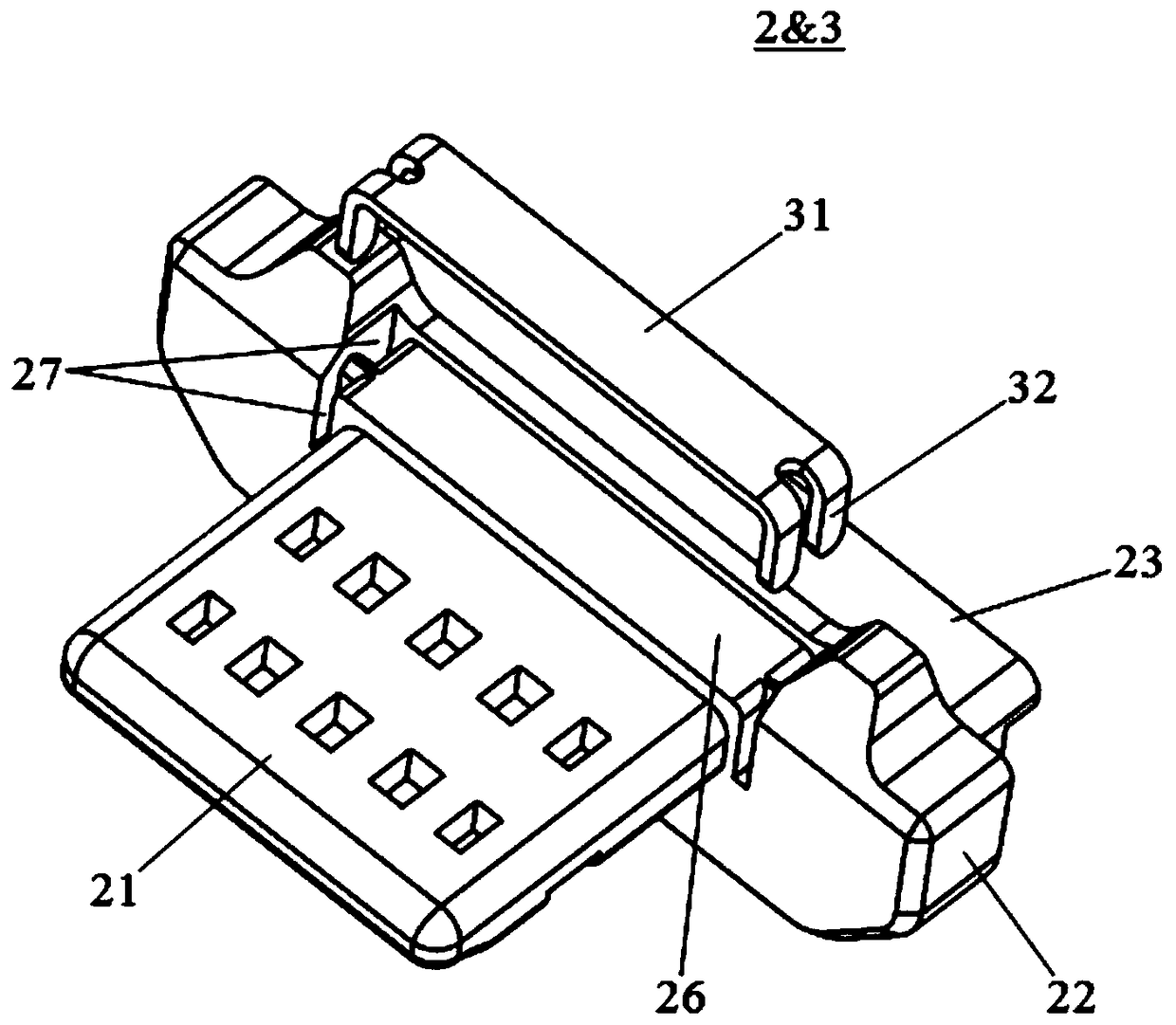

[0034] The plastic body 2 includes a bottom support part 21 that supports and fixes the plug-in section of the metal terminal 1, a sealing connection part 22 that fits squarely with the inner contour of the main metal housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com