Pruning trolley for municipal green belt

A green belt and municipal technology, applied in the direction of cutters, agricultural machinery and tools, applications, etc., can solve problems such as low efficiency, trouble, and lack of functions, and achieve good results, convenient use, high efficiency, and neat trimming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

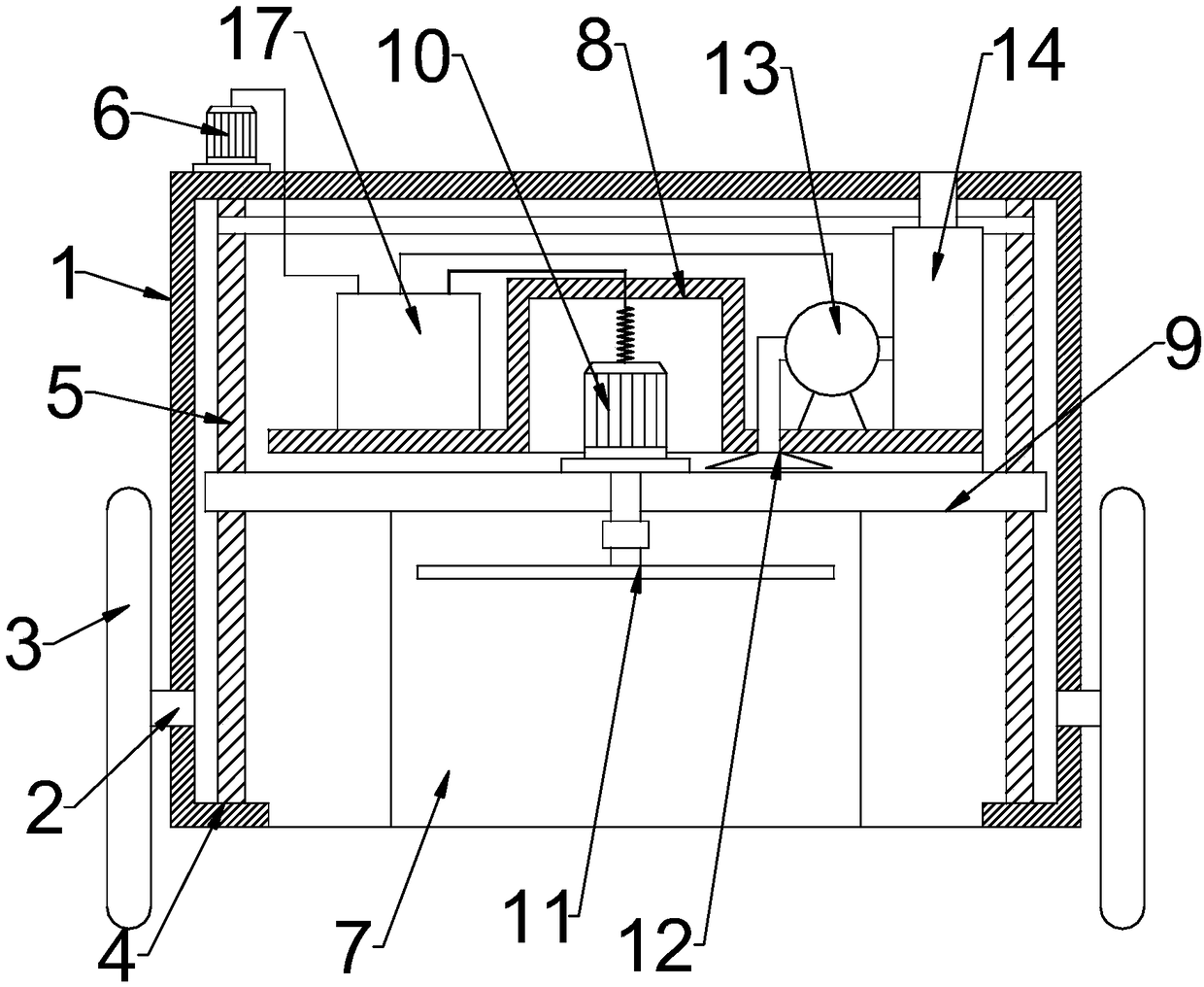

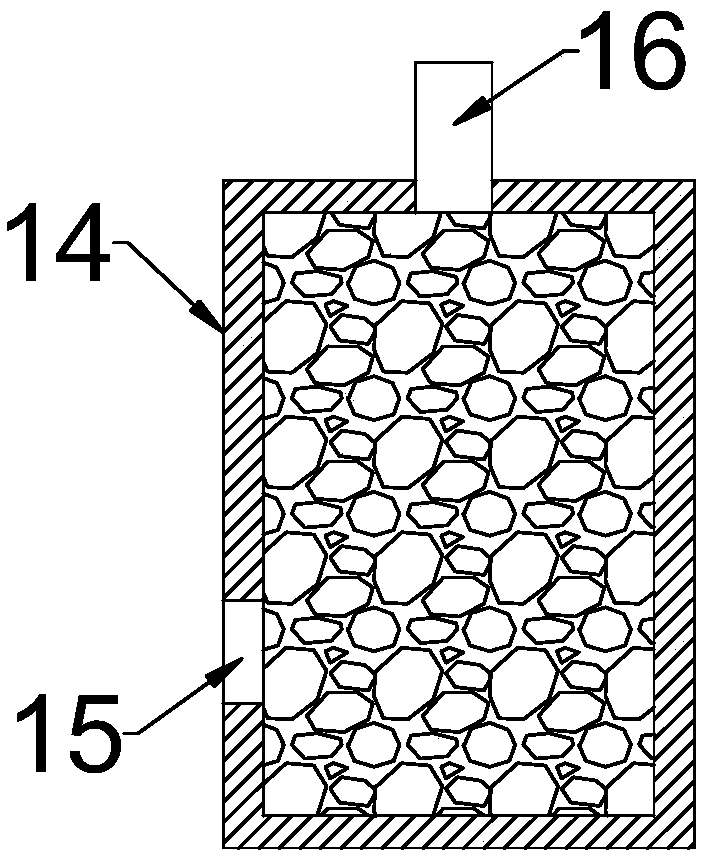

[0021] see Figure 1~2 , in an embodiment of the present invention, a trimming trolley for municipal green belts includes a housing 1, a lifting mechanism and a cutting mechanism, the lower end of the housing 1 is integrally formed with a flange 4, and the two sides of the housing 1 A road wheel 3 is provided in rotational connection with the first rotating shaft 2 .

[0022] The housing 1 is a cavity structure with an open lower end, an opening 7 is provided through the rear side wall of the housing 1, and a placement plate 8 is welded between the upper part of the front and rear side walls of the housing 1, and the placement board 8 It is a "ji" character structural plate.

[0023] Described elevating mechanism is made up of threaded support rod 5, first motor 6 and lifting plate 9, and described threaded support rod 5 is symmetrically vertically arranged above described flange 4, and described threaded support rod 5 lower ends and described flange 4 Rotation connection, t...

Embodiment 2

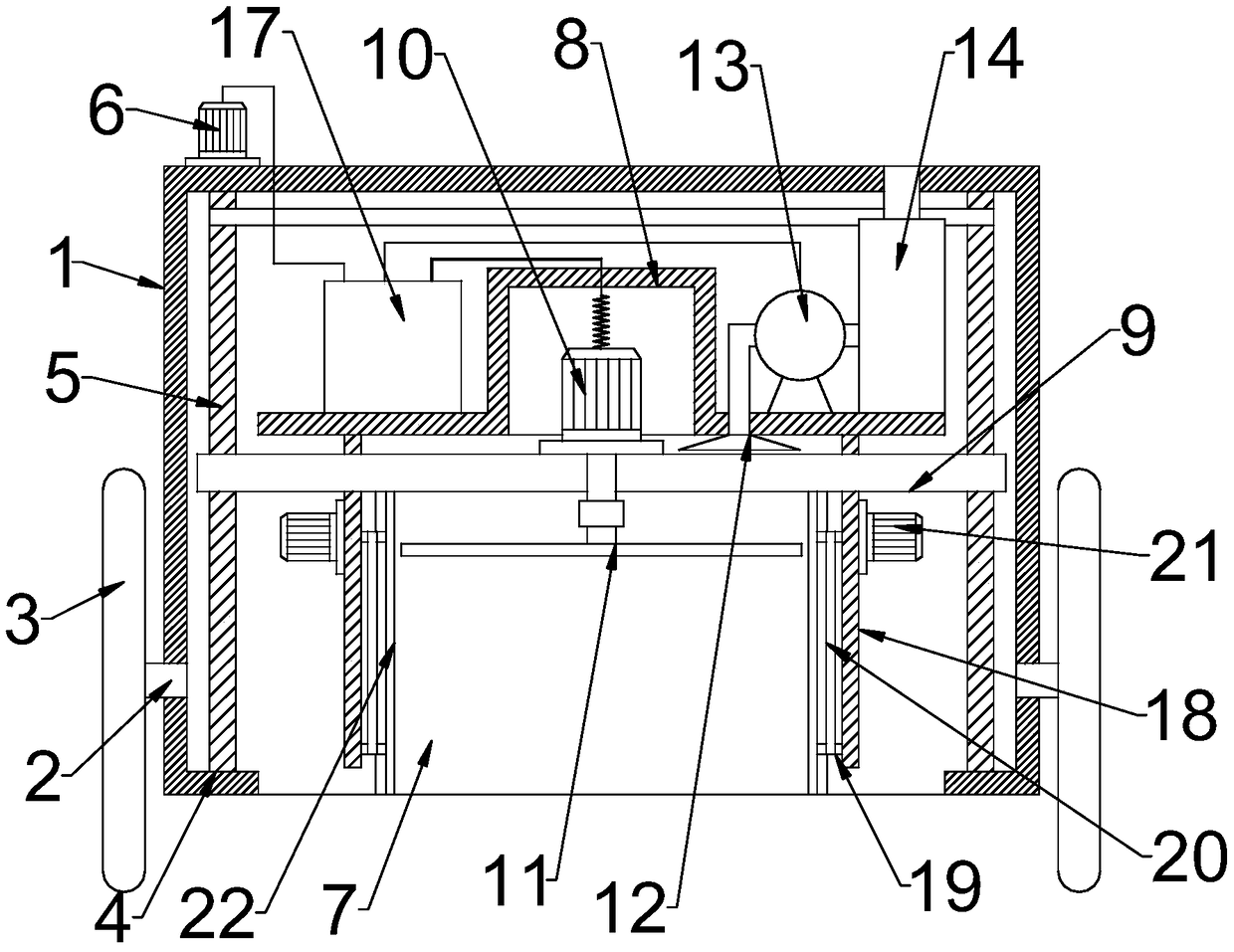

[0027] see image 3 , in the embodiment of the present invention, a kind of pruning trolley of municipal green belt, on the basis of embodiment 1, described cutting mechanism is divided into lateral cutting mechanism and horizontal cutting structure, and vertical direction movement of lifting mechanism synchronously drives horizontal cutting mechanism Movement, the horizontal cutting mechanism and the lateral cutting mechanism form a height-adjustable "gate"-shaped cutting.

[0028] Described lateral cutting mechanism is made up of second rotating shaft 19, transmission wheel 20, the 3rd motor 21 and cutting belt 22, and described lateral cutting structure is arranged on the side plate 18, and described side plate 18 is welded and arranged on the The lower end of the placement plate 8 is arranged symmetrically on both sides of the opening 7 .

[0029] The second rotating shaft 19 is rotatably arranged on the side of the side plate 18 and there are two from top to bottom. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com