Online chain plate conveying equipment

A technology of conveying equipment and chain plates, which is applied in the field of on-line chain plate conveying equipment, can solve the problems of high manufacturing and use costs, large workshop area, and large volume, and achieve low manufacturing and use costs, good friction and bite force , the effect of taking up little space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

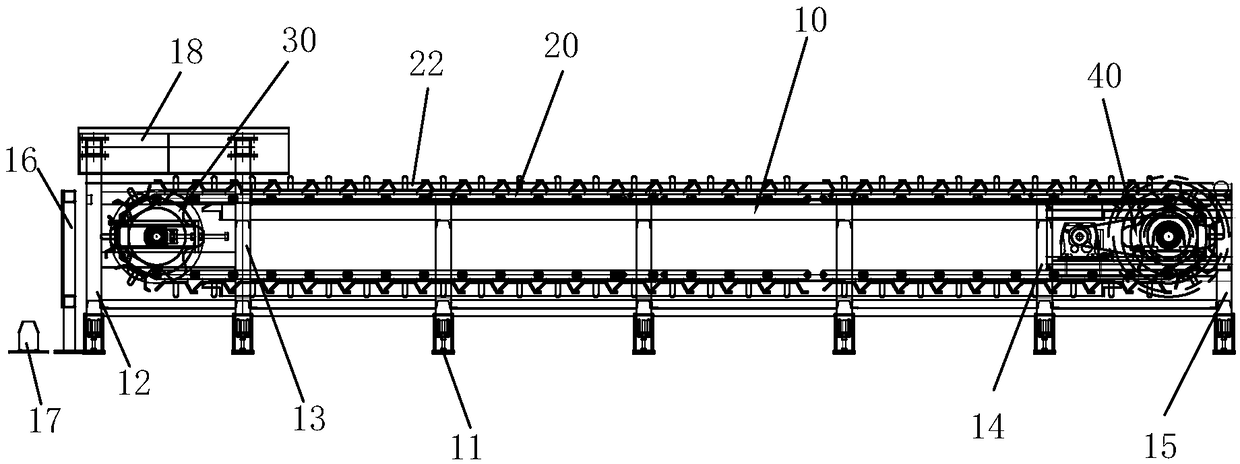

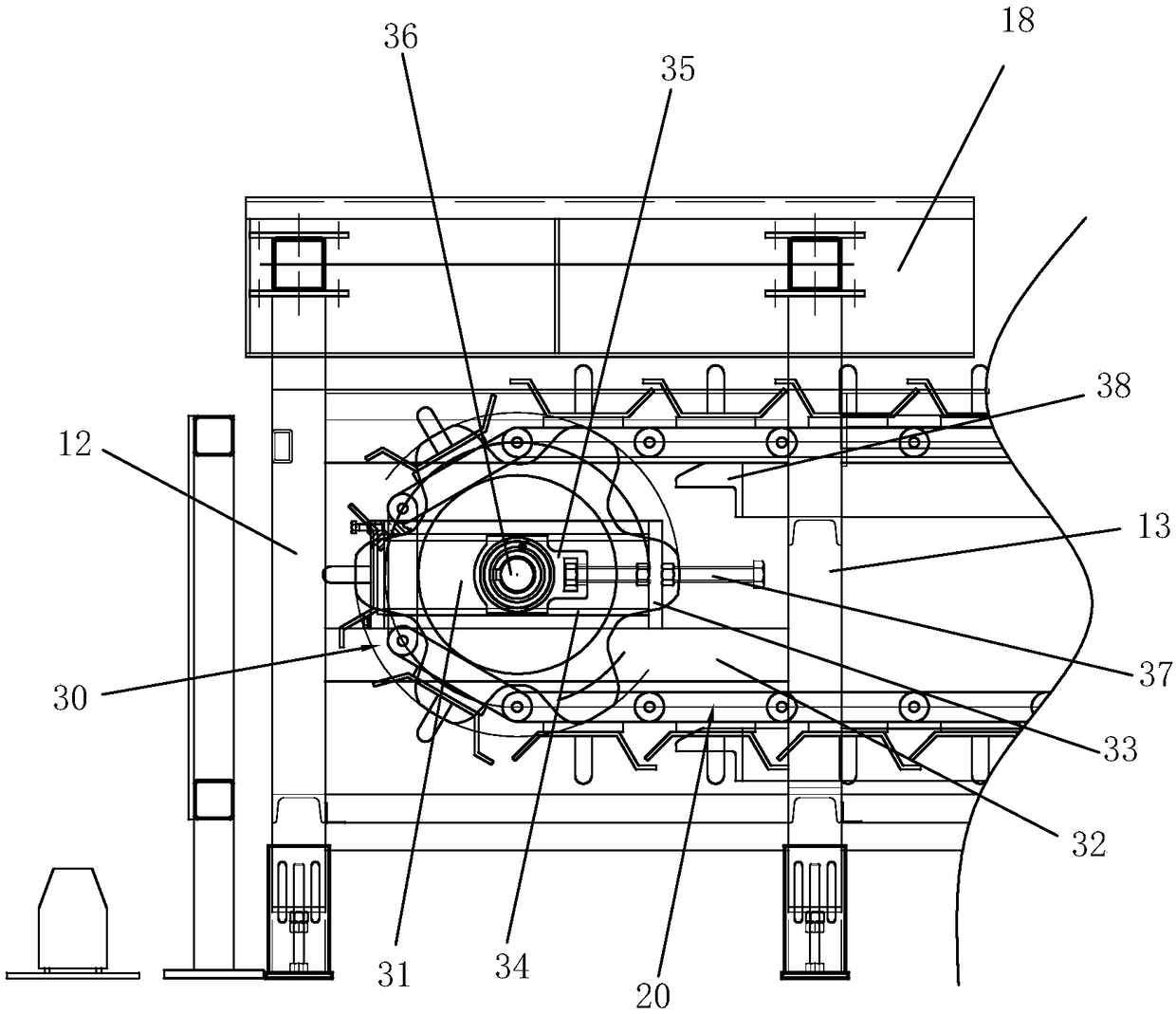

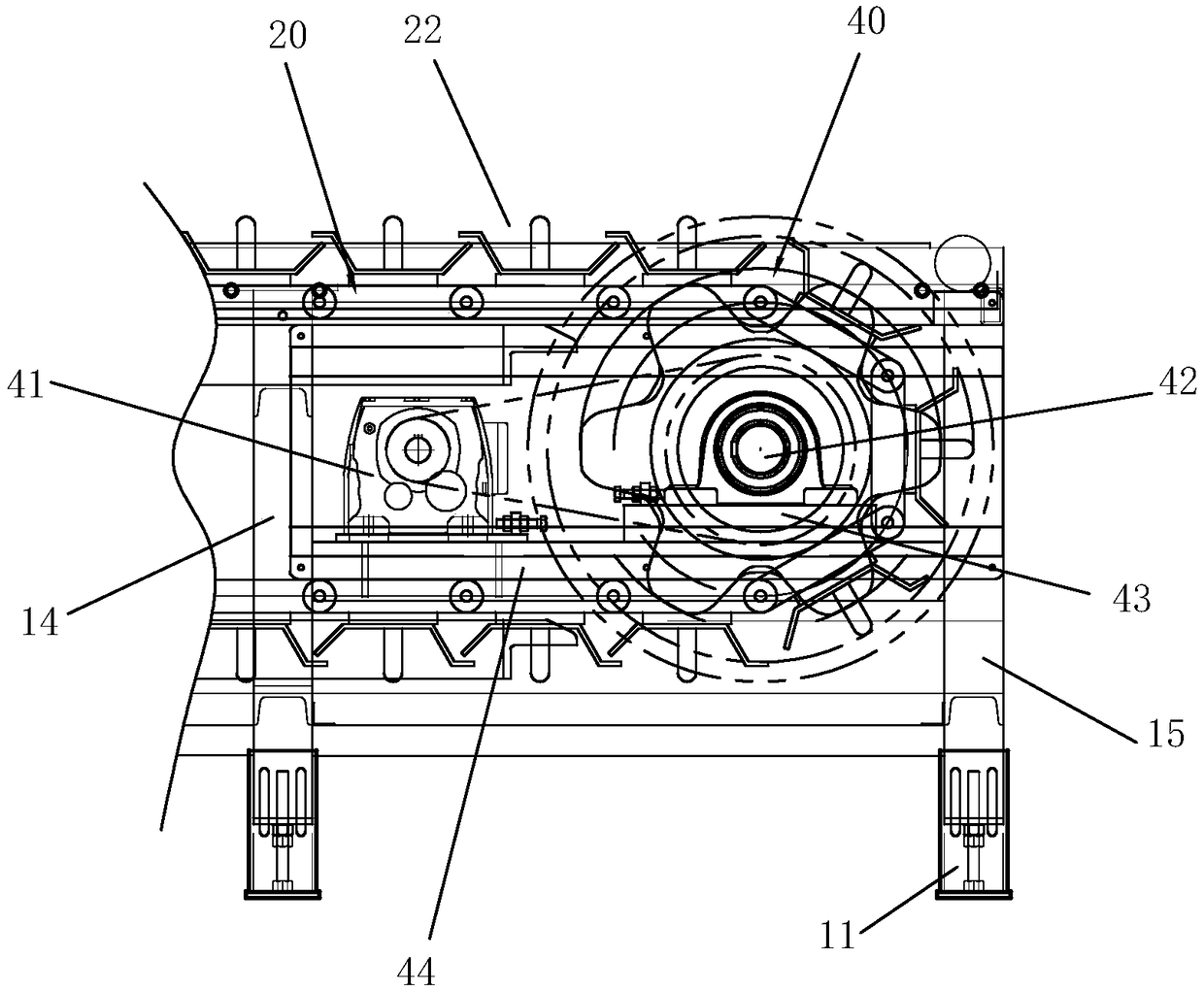

[0013] Such as Figure 1 to Figure 4 As shown, a kind of on-line chain plate conveying equipment of the present invention comprises an elongated frame body 10, and the elongated frame body 10 is supported and fixed by seven support seats 11, and support rods are arranged on the upper ends of the seven support seats 11, respectively For the first support bar 12, the second support bar 13, to the sixth support bar 14 and the seventh support bar 15, the front end of the first support bar 12 is provided with an anti-collision barrier 16, and the anti-collision barrier 16 is used to prevent the Collision with other tools when using, also be provided with head anti-collision block 17 at anti-collision barrier 16 front ends. A material guide groove 18 is provided at the upper end of the first support rod 12, and the material guide groove 18 is used for guiding and unloading during feeding.

[0014] Such as Figure 1 to Figure 4 As shown, a circular closed metric pitch roller chain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com