Mechanism for measuring starting torque and constant-torque rotary angle

A technology of turning angle and starting torque, which is applied in the field of measuring starting torque and constant torque measuring turning angle mechanism, can solve problems such as excessive deviation, only angle measurement, and invalid measurement results, so as to reduce operation actions, reduce manufacturing costs, The Effect of Simplifying Complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

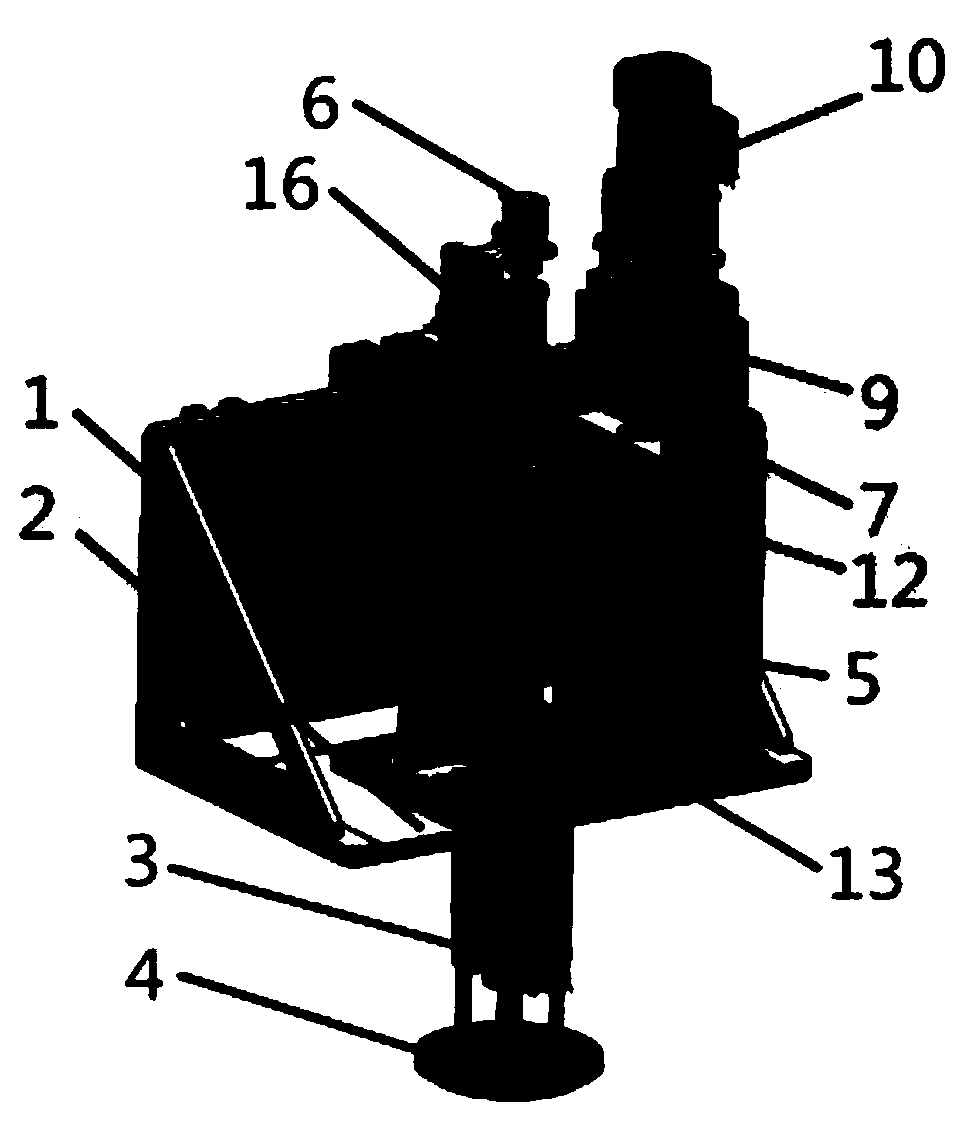

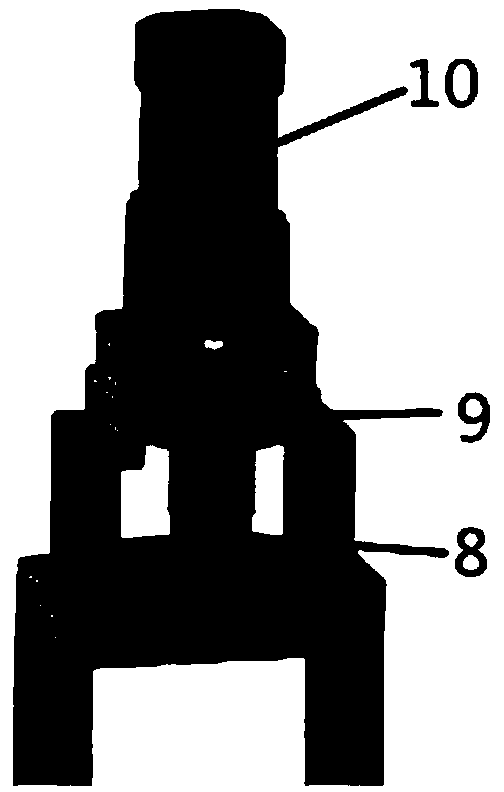

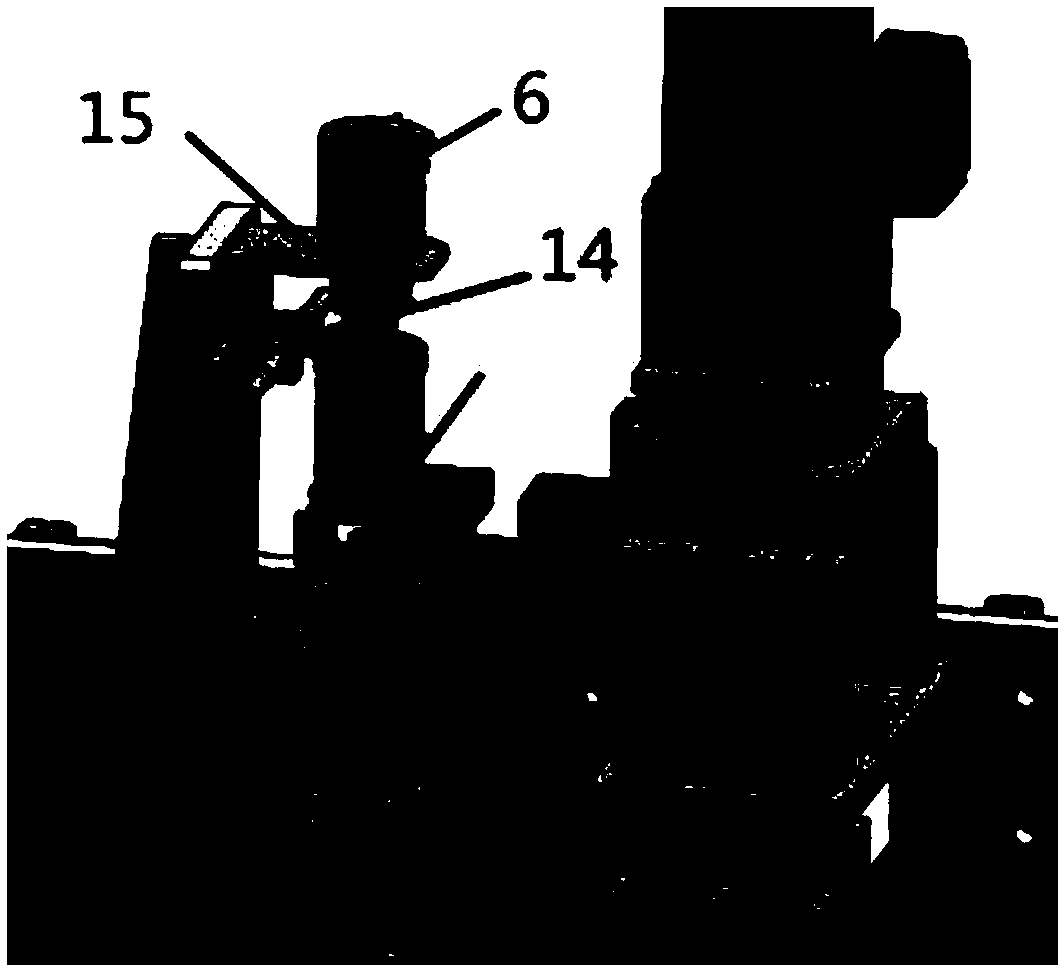

[0018] Refer to attached Figure 1-3 As shown, a mechanism for measuring the starting torque and constant torque for measuring the rotation angle includes a frame 1, the bottom plate 2 of the frame 1 is provided with a measuring shaft 3, and the bottom end of the measuring shaft 3 is set through the bottom plate 2 , the bottom end of the measuring shaft 3 is provided with a gear drive head 4, the measuring shaft 3 is provided with a torque sensor 5, and the torque sensor 5 is arranged above the bottom plate 2, and on the measuring shaft 3 An angle sensor 6 is also provided, and the angle sensor 6 is set on the top of the measuring shaft 3, and the measuring shaft 3 is also sleeved with a timing belt 7, and the timing belt 7 is sleeved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com