Method of testing interior amplitude of concrete during pouring and vibrating

A technology of pouring vibrating and testing methods, which is applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, and using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. It can solve the problems that the internal dynamics of concrete cannot be accurately grasped, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in combination with the accompanying drawings, and specific implementation methods will be given.

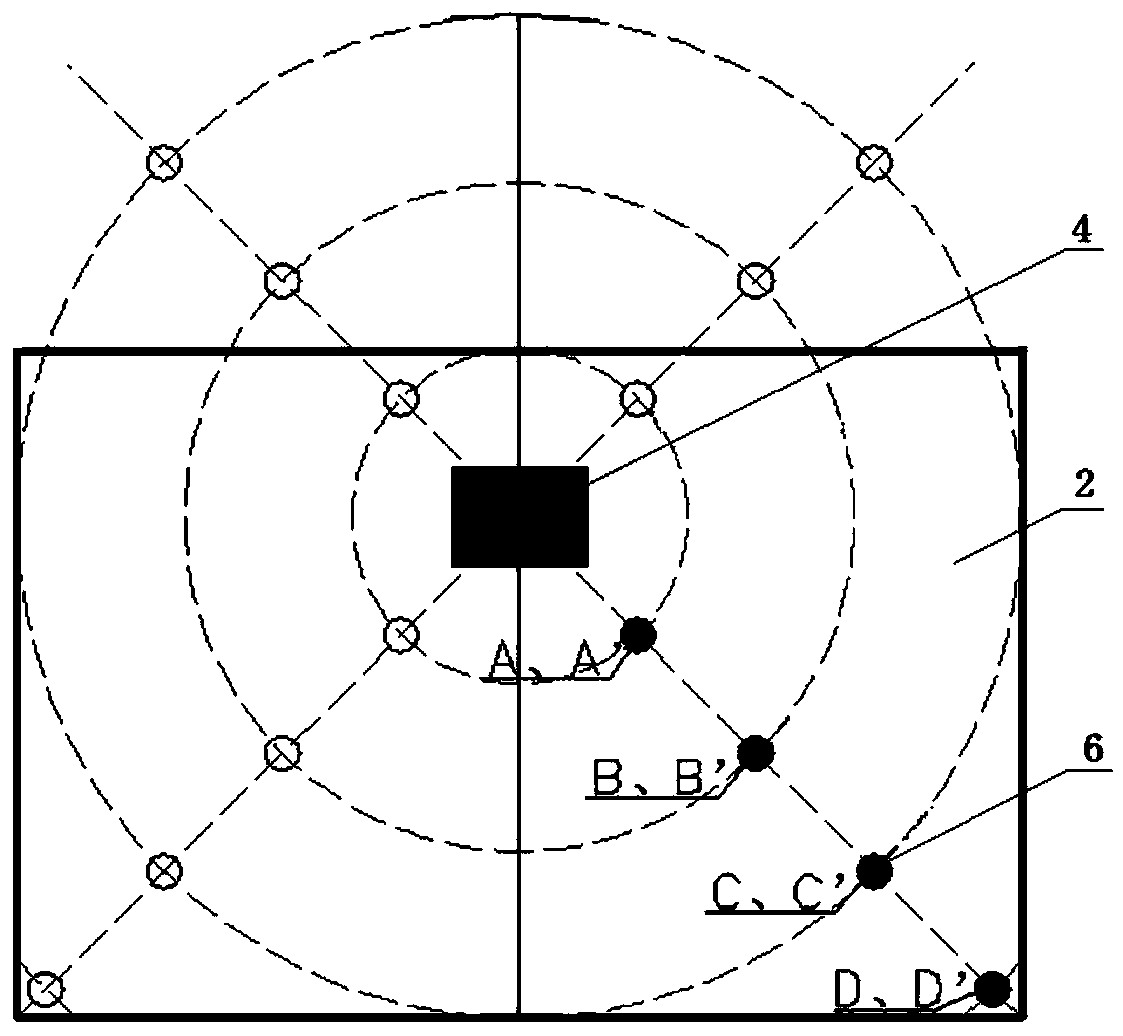

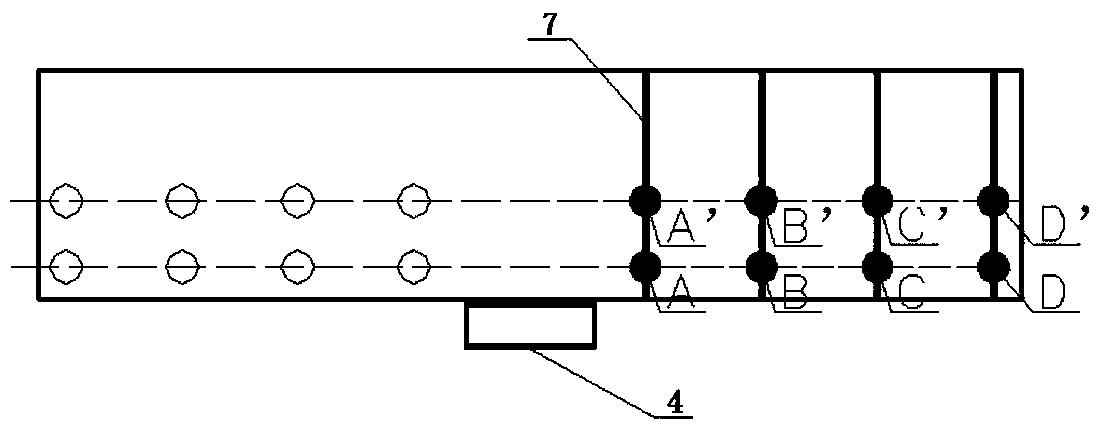

[0018] Such as figure 1 , 2 , Shown in 3, a kind of test method of concrete internal vibration amplitude in the process of testing pouring vibration, comprises the following steps:

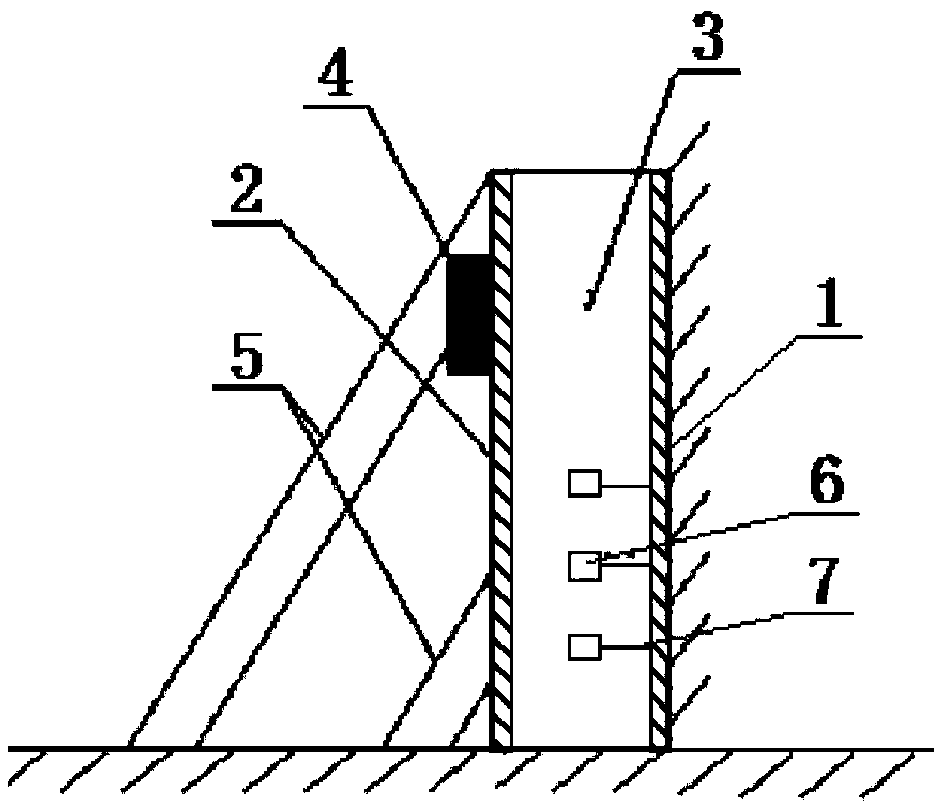

[0019] first step, such as figure 1 As shown, a retaining wall 1 is prefabricated to simulate the initial supporting surface of the tunnel, and a steel formwork 2 parallel to the retaining wall 1 is set on one side of the retaining wall 1, and two vertical Based on the blocking plate 3 of the retaining wall 1, the retaining wall 1, the steel formwork 2 and the two plates 3 form a pouring cavity for pouring the simulated tunnel lining, and the distance between the retaining wall 1 and the steel formwork 2 is the thickness of the simulated tunnel lining. The steel formwork 2 has the same size as the retaining wall 1, so the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com