priority diverter valve

A diverter valve, spool technology, used in multi-port valves, valve devices, fluid steering mechanisms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

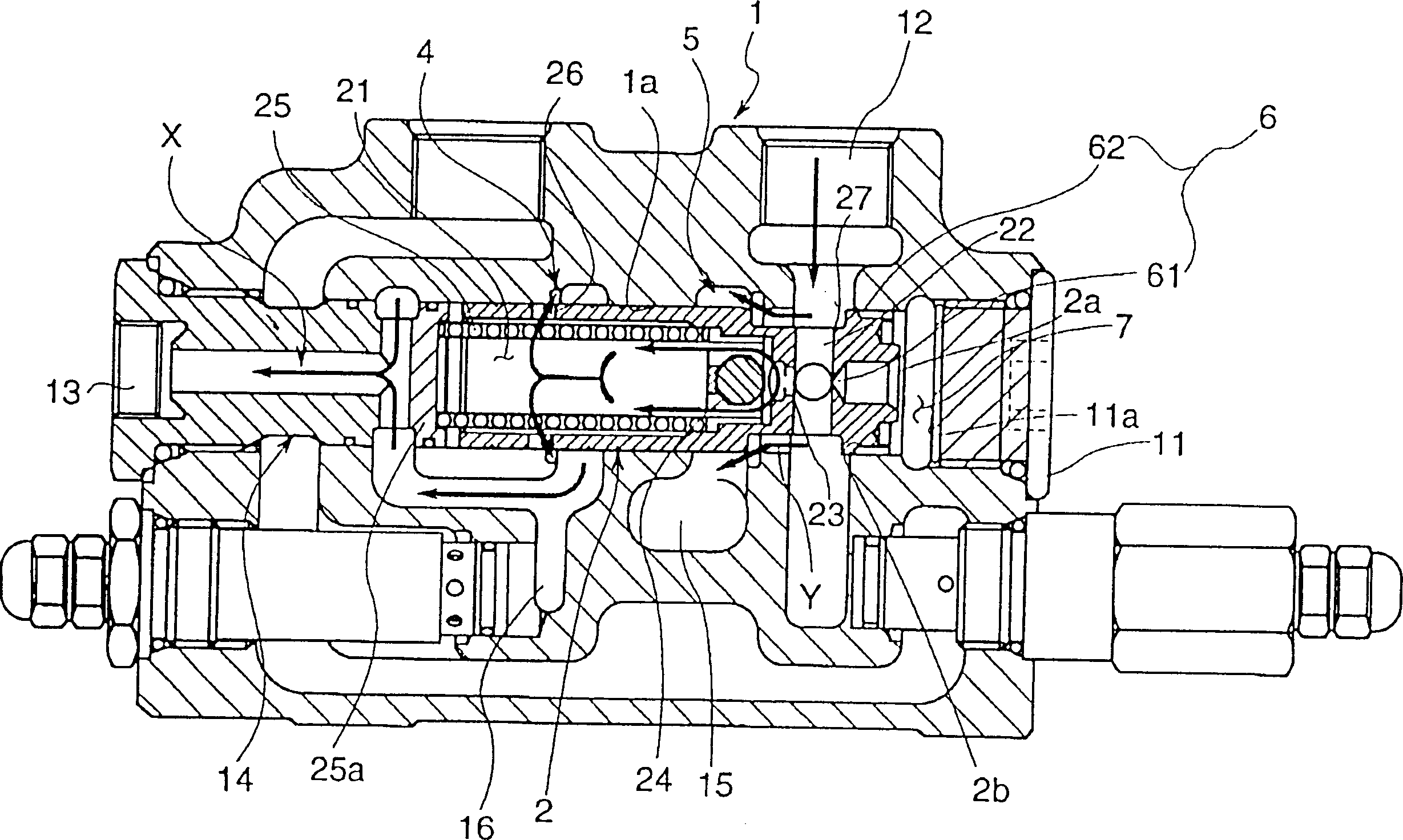

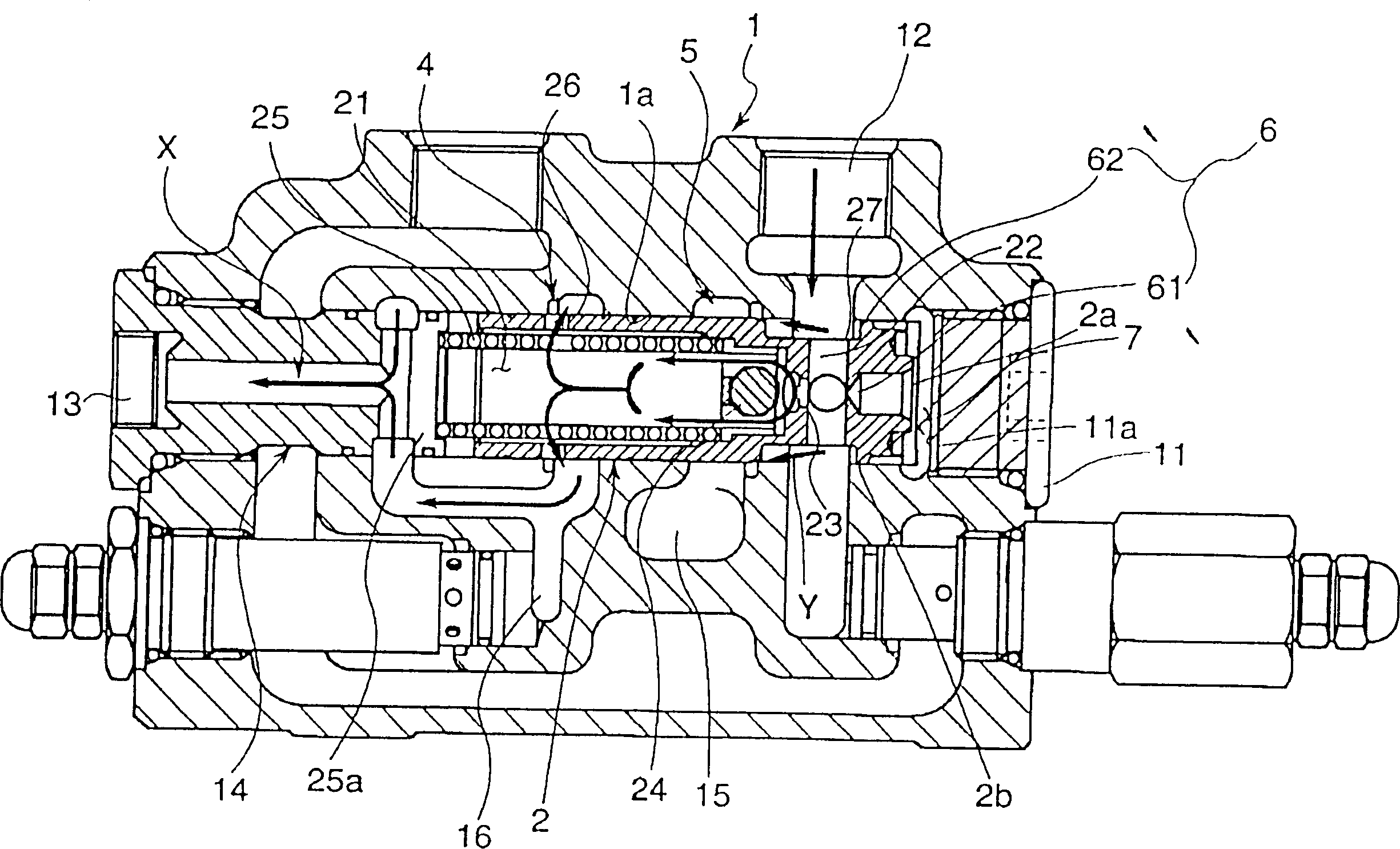

[0022] An embodiment of the present invention will be described below with reference to the drawings.

[0023] The priority diverter valve of this embodiment, for example, is used for forklifts, and the pressurized liquid such as oil provided from the common hydraulic source is preferentially diverted to the steering control, and the remaining part is diverted to the loading and unloading control according to the requirements, such as figure 1 As shown, the main body 1 is equipped with a spool 2 and a spring 25 to form.

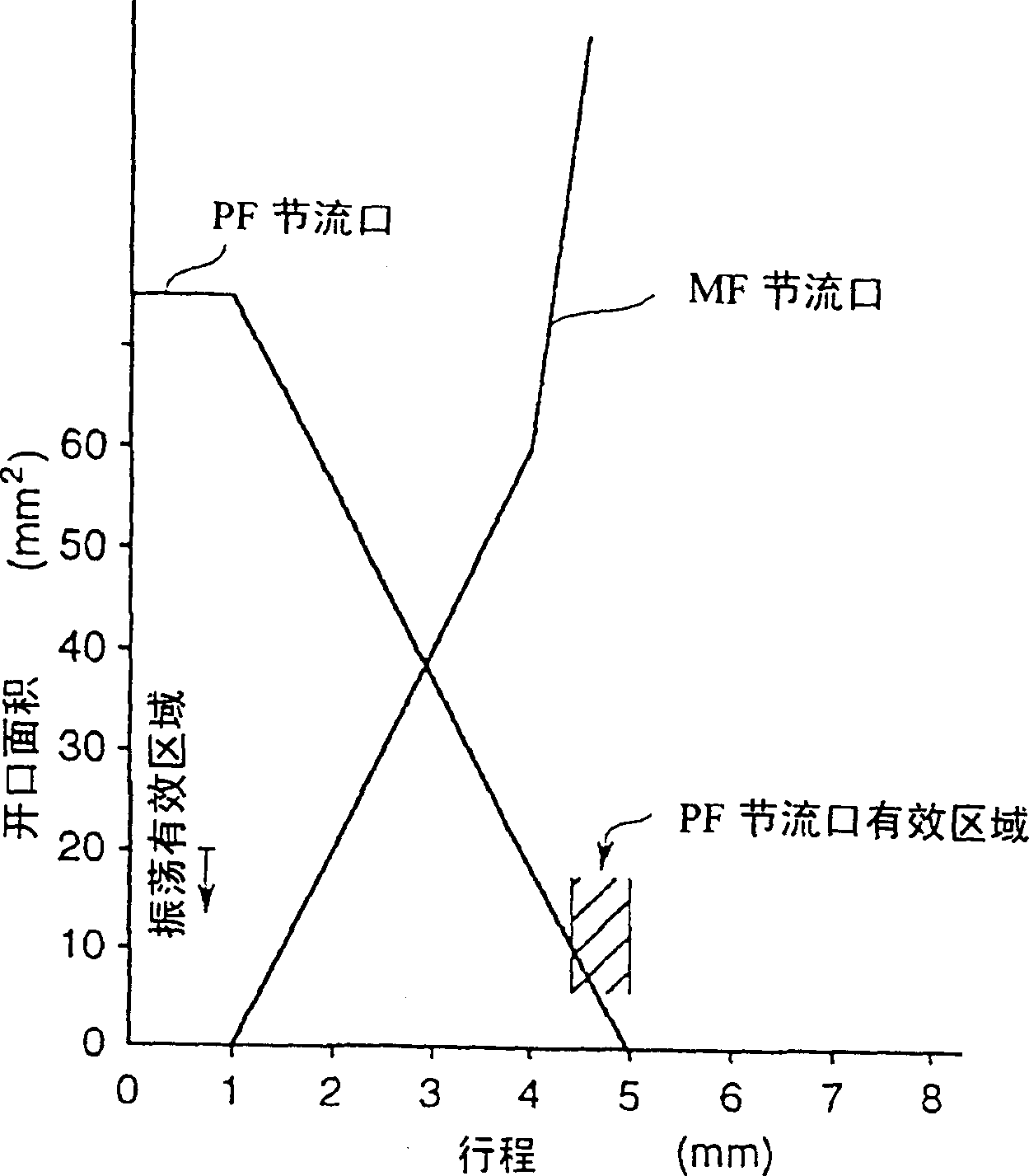

[0024] There is a spool guide hole 1a in the body 1, the spool 2 is inserted in the spool guide hole 1a, and one end of the guide hole is blocked with a plug 11. In the main body, a high-pressure port 12 is provided at one end of the spool guide hole 1a, and a steering port 13 is provided at the other end of the port through a priority control joint 14 . In addition, at the position close to the interface 12 in the main body, while the loading and unloading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com