Conveyor for cold rolls after processing

A technology of conveying device and cold roll, which is used in transportation and packaging, trolley accessories, multi-axis trolley, etc., can solve the problems such as the inability to shock absorption, the inability to place cold rolls of different lengths through adjustment, and the inconvenience of placement and transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

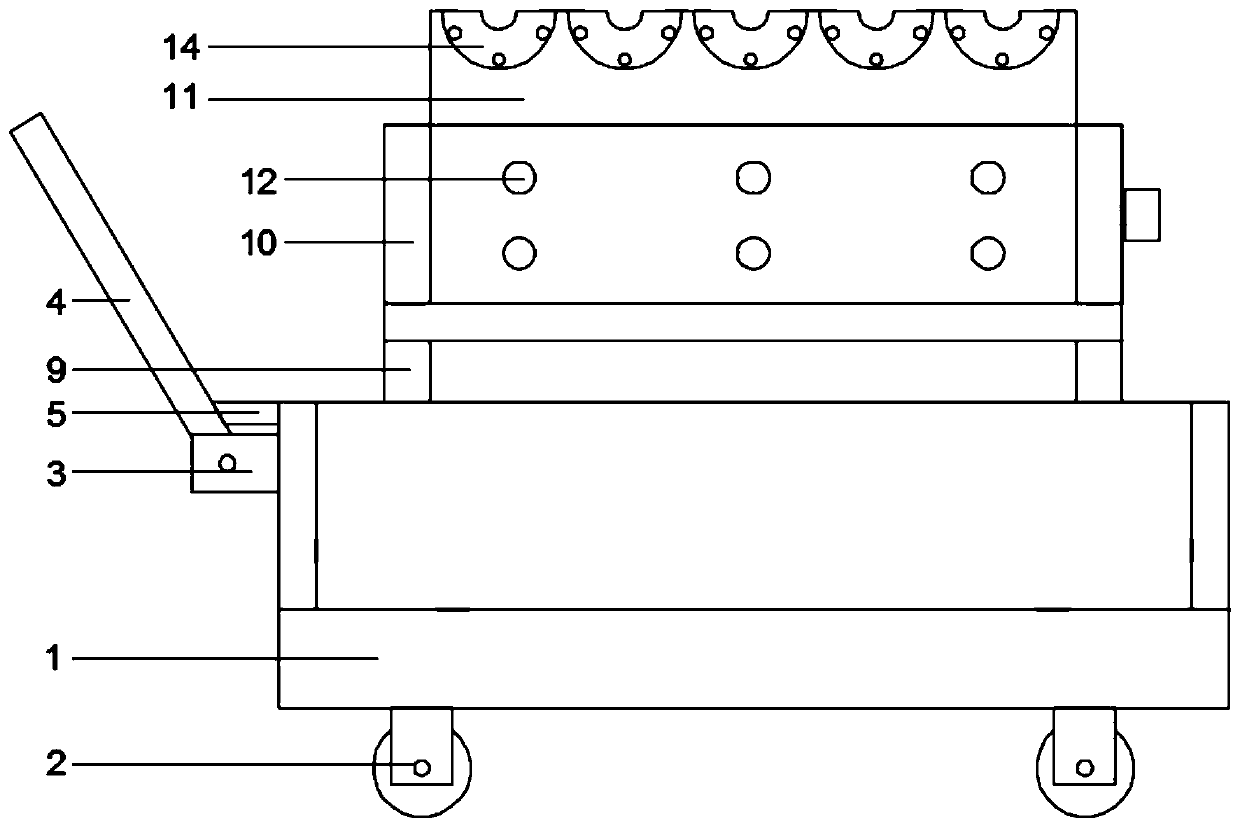

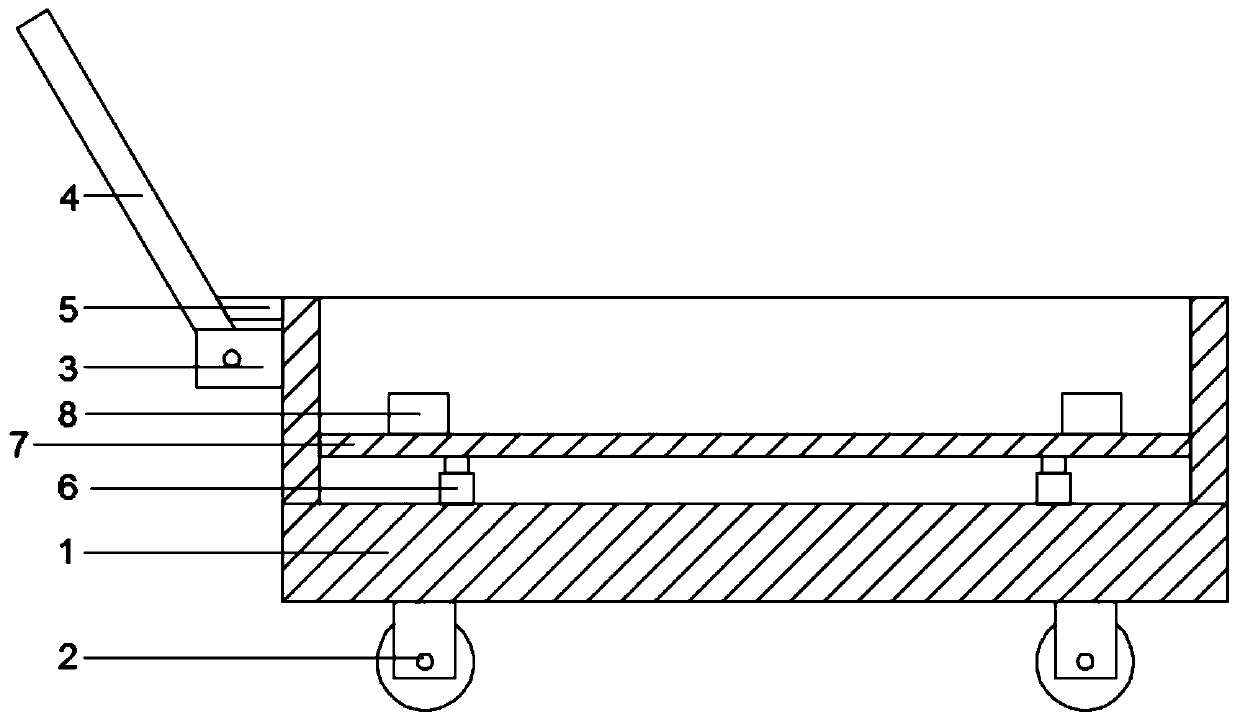

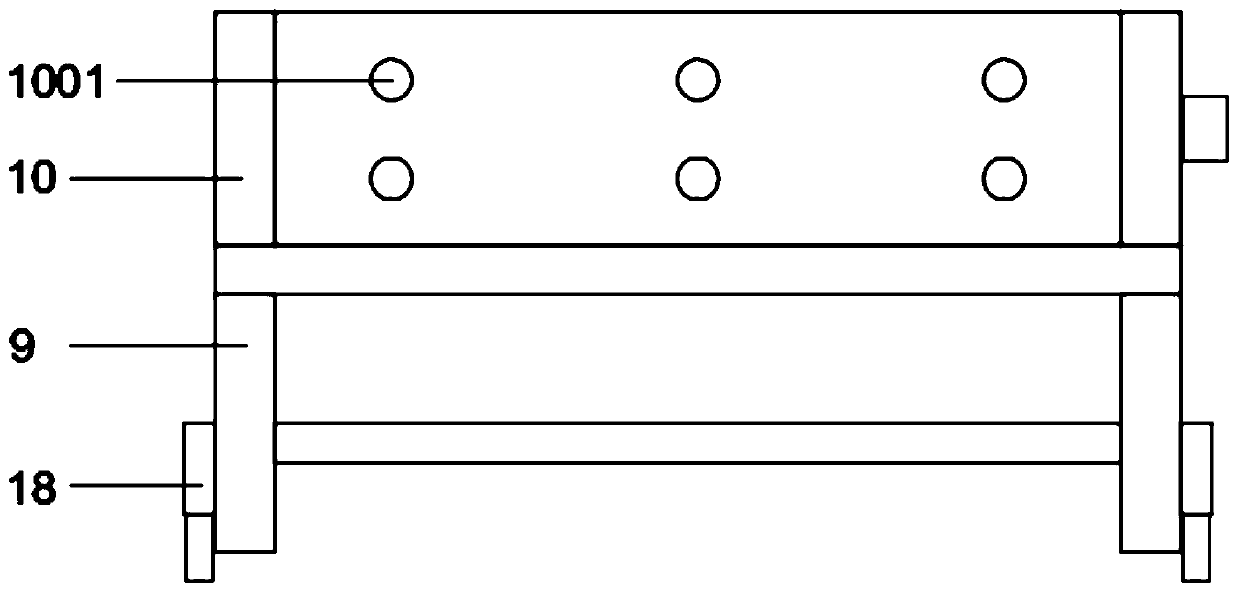

[0037] as attached figure 1 To attach Figure 9 Shown:

[0038] The present invention provides a conveying device for cold roll processing, including: cart body 1, universal wheel 2, rotating fixed frame 3, cart handle 4, trapezoidal iron 5, elastic telescopic rod A6, rectangular plate A7, Limiting angle iron 8, rectangular support frame 9, rectangular frame 10, circular hole A1001, rectangular plate B11, circular hole B1101, semicircular groove A1102, fixed shaft 12, semicircular plate A13, semicircular groove B1301, semicircular Plate B14, semicircular groove C1401, fixed pin 15, fixed bolt 16, jack structure 17 and elastic telescopic rod B18; four universal wheels 2 are welded on the bottom surface of the cart main body 1 in a rectangular array, and the cart main body 1 There is a rotating fixed frame 3 welded at the position above the left end face; the rotating fixed frame 3 is connected with a cart handle 4 through the rotation of the latch; the inner top surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com