Bulk grain silo deep reverse sampling device and method

A technology of cutting samples and grain tubes, which is applied in the field of bulk grain silo sampling, which can solve the problems of increasing the content of light impurities in samples, increasing the brokenness of automatic grading, and increasing detection errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

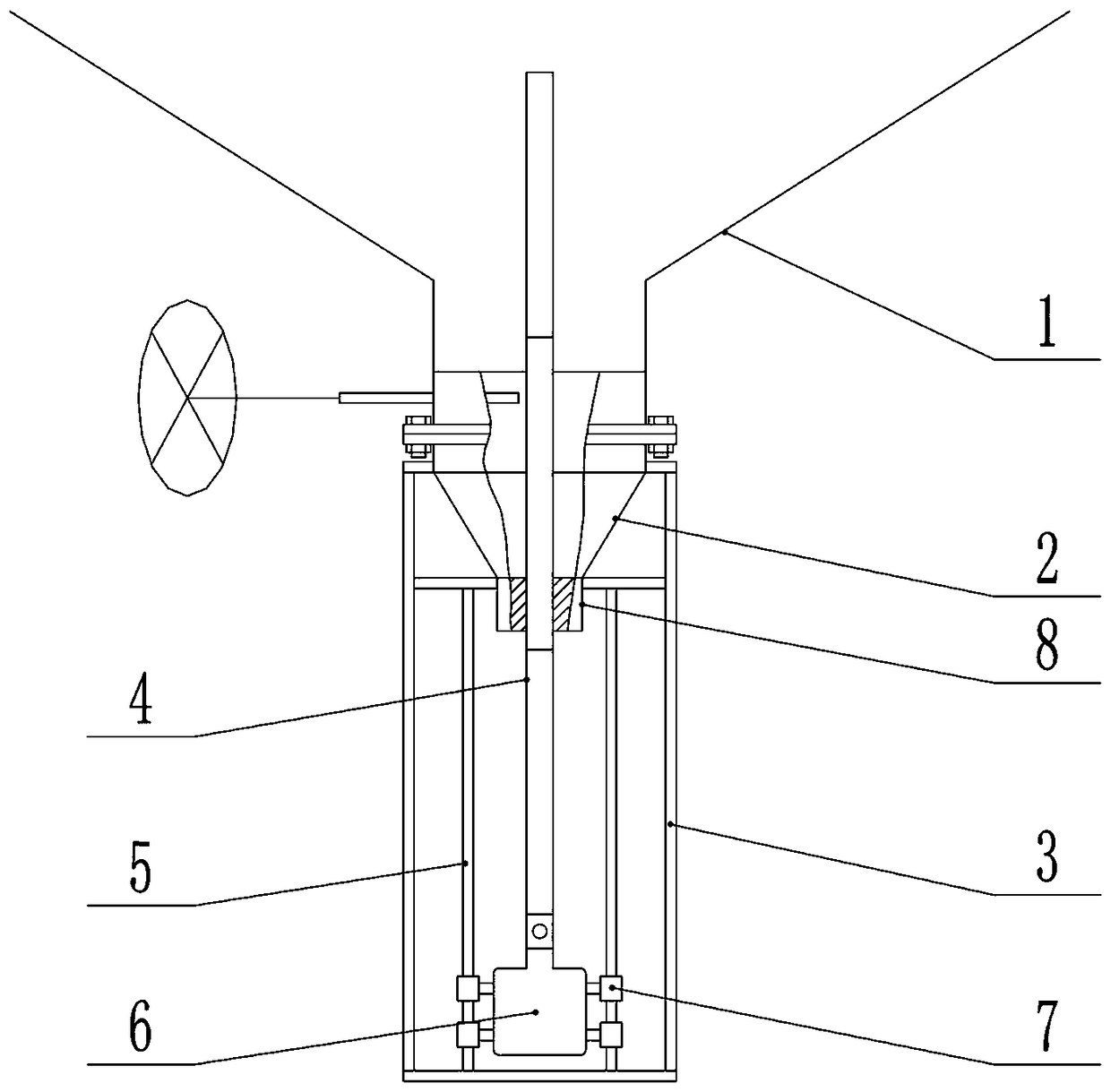

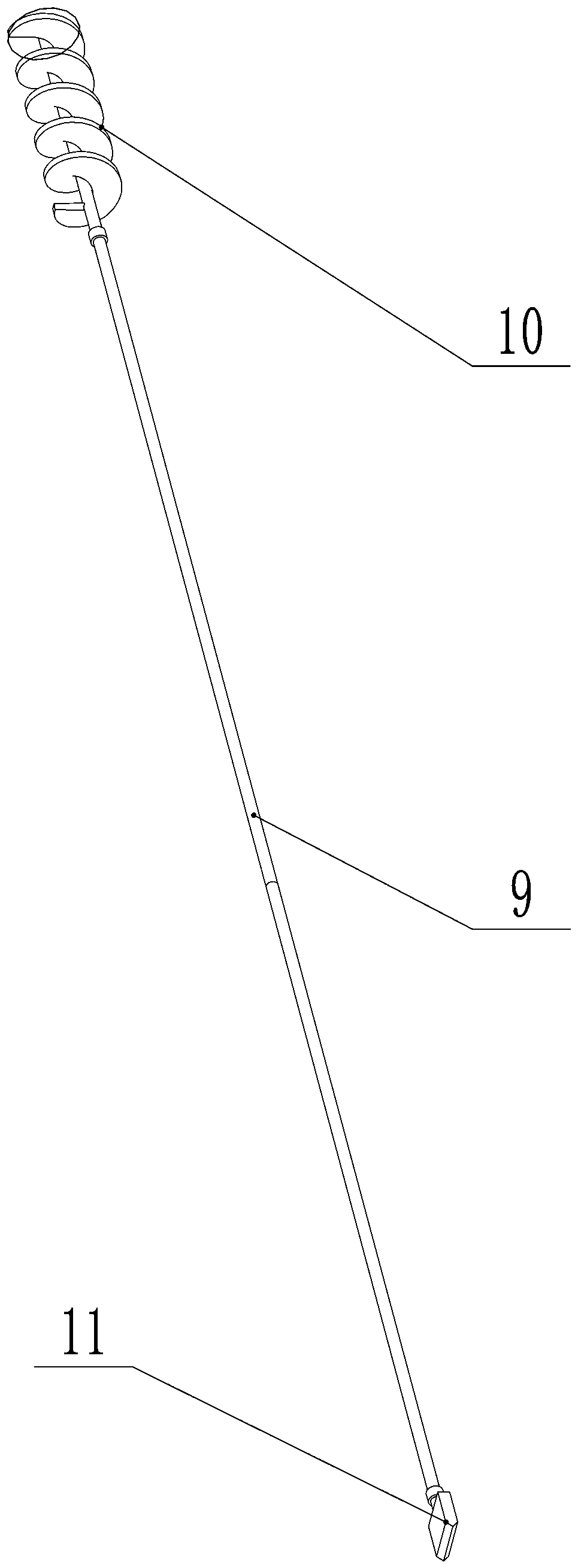

[0022] Such as figure 1 , figure 2 As shown, a deep reverse sampling equipment for a bulk grain silo includes a fixed frame 3, a driving mechanism arranged on the fixed frame 3, a threaded interface 8 and a sampling tube 4, and the driving mechanism includes a vertical guide rail 5 , a group of slide assemblies 7 arranged on the vertical guide rail 5, a motor 6 installed on the slide assembly 7, the motor 6 drives the rotation of the sample tube 4, and the inner wall of the threaded interface 8 is set An internal thread, the outer wall of the sample tube 4 is provided with an external thread suitable for the internal thread.

[0023] The method of using the deep layer reverse sampling equipment of the bulk grain silo is as follows. First, the threaded interface 8 is fixed on the bottom of the grain silo through fixing components such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com