Device and method for measuring lateral stress and strain during movement of loose particles

A particle movement and fixing device technology, applied in measurement devices, fluid dynamics tests, particle and sedimentation analysis, etc., can solve the problem of inability to obtain more accurate distribution of loose particles, inability to obtain lateral stress distribution, and limited qualitative and quantitative research, to achieve the effect of improving understanding and research level, convenient measurement and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

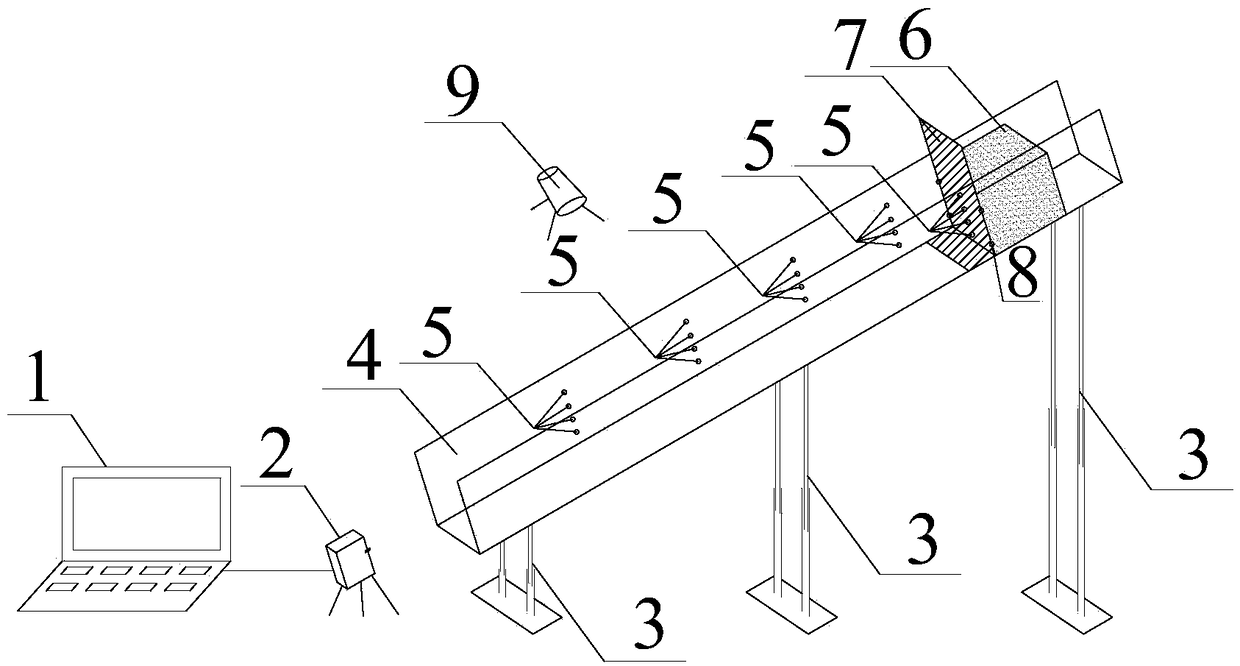

[0023] Such as figure 1 As shown, the device for measuring the lateral stress and strain during the movement of loose particles includes a support 3, a flow chute 4, a rigid baffle 7, a fixing device 8 and an earth pressure sensor 5, and the flow chute 4 consists of two sides and a bottom surface, the circulation chute 4 is installed on the support 3, and an angle is set between the circulation chute 4 and the horizontal plane; the rigid baffle 7 includes a vertical plate and a bottom plate, and the vertical plate Vertically arranged in the middle of the bottom plate, the rigid baffle 7 is placed on the bottom surface of the circulation chute 4, and the fixing device 8 is used to position the rigid baffle 7 on the circulation chute 4; The earth pressure sensor 5 is provided on the side of the circulation chute 4 and on the vertical plate of the rigid baffle 7 . The support 3 is a height-adjustable column, and the angle between the circulation chute 4 and the horizontal plane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com