Gluing process optimization method and filter tip ventilation rate control method

A technology of process optimization and ventilation rate, applied in general control system, adaptive control, control/regulation system, etc., can solve problems affecting the quality stability of cigarette products, filter ventilation rate index fluctuating smoke, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The gluing process optimization method based on filter ventilation rate control in this embodiment.

[0023] Step (1), take samples for each shift on different machines in continuous production

[0024] A. Sample specification: Take a certain domestic brand of cigarettes.

[0025] B. Sampling quantity and frequency: Samples are taken once per shift on the continuous production machine, one sample each time, and 5 consecutive days of sampling, that is: 1 sample / shift / machine×5 days.

[0026] C. Sampling machine: machines No. 1, 2, 3, 4, 5, 6, and 7 (M5 model) in Zone B of the packaging workshop.

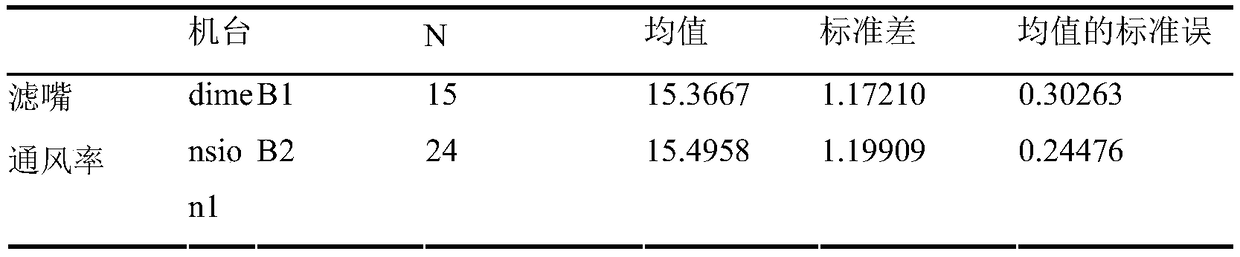

[0027] Step (2), the filter tip ventilation rate of the sample of detection step (1);

[0028] A. Detection indicators

[0029] The physical indicators to be tested include: filter ventilation rate, total ventilation rate, weight, draw resistance (PD), and closed draw resistance (CPD), which are tested according to the requirements of the national cigarette standard. Table ...

Embodiment 2

[0105] The gluing process optimization method based on filter ventilation rate control in this embodiment.

[0106] In step (4), build model 2 (without intercept)

[0107]

[0108] Table 21 Test of Intersubject Effect of Interaction of Spray Glue and Glue

[0109]

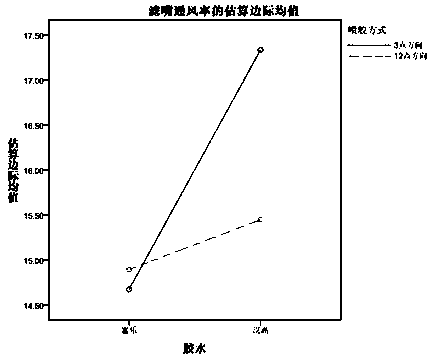

[0110] From the analysis of the above model, it can be seen that:

[0111] The significance probability Sig. values of model 2 are all 0, far less than 0.05, indicating that the model is applicable, but from R2, no intercept model is preferred. The model passed the variance homogeneity test, and the factor (glue), factor (glue spraying method), and factor (glue*glue spraying method) all had a significant impact on the index (filter tip ventilation rate).

[0112] Table 22 Pairwise comparison of the interaction between spray glue and glue based on Model 2

[0113]

[0114] It can be seen from Table 22 that both levels of the factor (glue spraying method) have a significant impact on the index (filter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com