A wind turbine generator cabin cover strength calculation method

A wind turbine and strength calculation technology, which is applied in calculation, electrical digital data processing, design optimization/simulation, etc., can solve the problems of inaccurate calculation of the strength of the nacelle cover, unreasonable simplification of materials, etc. Real, accurate results

Pending Publication Date: 2019-03-08

NANJING ZHONGREN ENERGY TECH

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] The purpose of the present invention is to provide a method for calculating the strength of the nacelle cover of a wind turbine. The present invention is based on the composite material finite eleme

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

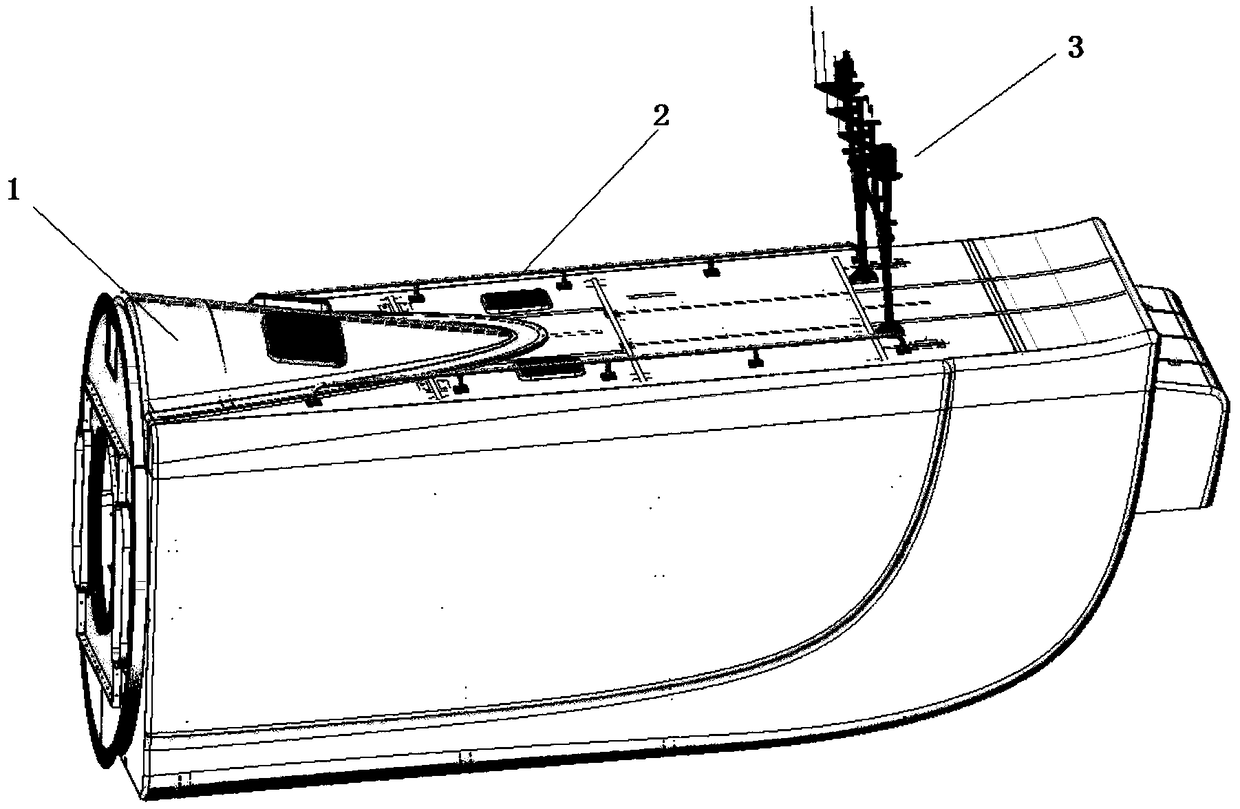

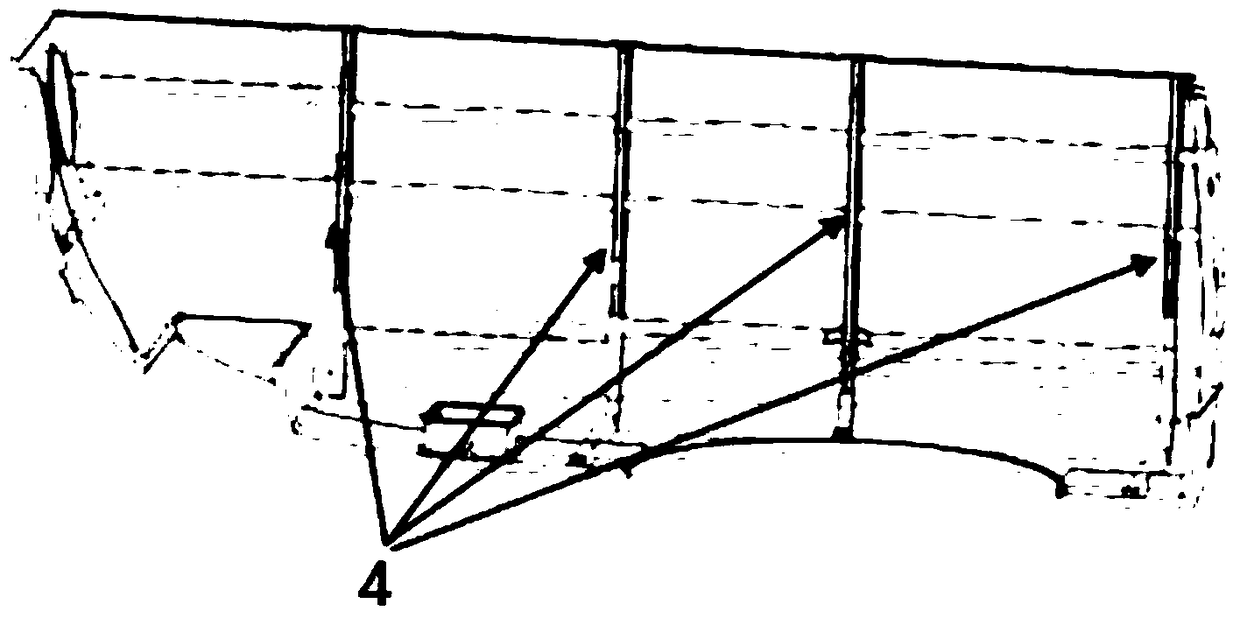

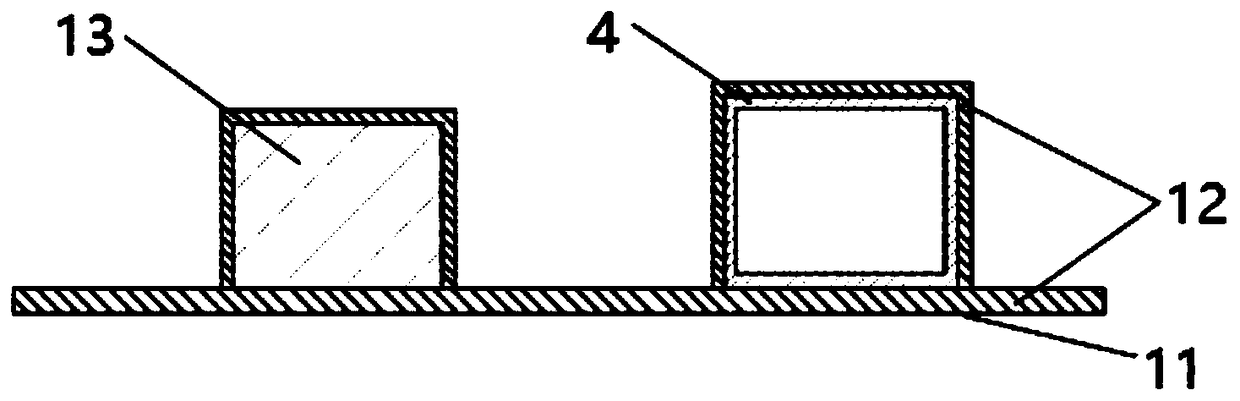

The invention provides a wind turbine generator cabin cover strength calculation method. The method comprises the steps of establishing a geometric model of a wind turbine generator cabin cover; importing the geometric model into finite element analysis software, and performing layering modeling on the housing of the cover body by applying a preprocessing function of the finite element simulationsoftware; defining material attributes and section attributes of each component of the cabin cover, establishing a finite element model of the cabin cover of the wind turbine generator, and respectively defining Young's modulus and Poisson's ratio of the glass fiber layer in different directions when defining the material attributes; applying boundary conditions and loads to the finite element model of the wind turbine generator cabin cover; calculating the single-layer stress strain of the glass fiber reinforced plastic part of the wind turbine generator cabin cover; and evaluating the strength of the composite material by adopting a composite material strength failure criterion. According to the method, the composite material lamination modeling is carried out, the material attributes are defined based on the orthogonal anisotropy of the material, and the maximum tensile and compressive strain criterion and the Tsai-Wu is used for judgment, so that the cabin cover stress simulation is more real, and the calculation result is more accurate.

Description

Technical field [0001] The invention belongs to the technical field of strength analysis of components of a wind power generator, and particularly relates to a method for calculating the strength of a wind power generator nacelle cover. Background technique [0002] With the continuous development of modern society, people's demand for energy is also growing rapidly. Traditional non-renewable energy sources are continuously restricted due to the environment and reserves. The country and the government are actively developing clean and renewable energy sources to replace traditional non-renewable energy sources. [0003] Wind energy is an important clean energy, which is of great significance to solving the global environmental and energy crisis. In recent years, domestic wind turbines have developed rapidly, so the safety of wind turbines is also very important. In order to ensure the reliability of the equipment, it is necessary to calculate and analyze the structure and fatigue ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G06F17/50

CPCG06F30/17G06F30/23Y02B10/30

Inventor 王杰孟庆鑫李壮睢广坤

Owner NANJING ZHONGREN ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com