Chain plate

A technology of chain plates and adjusting baffles, applied in the field of chain plates, can solve problems such as product lodging, and achieve the effect of preventing shaking and restraining product lodging problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

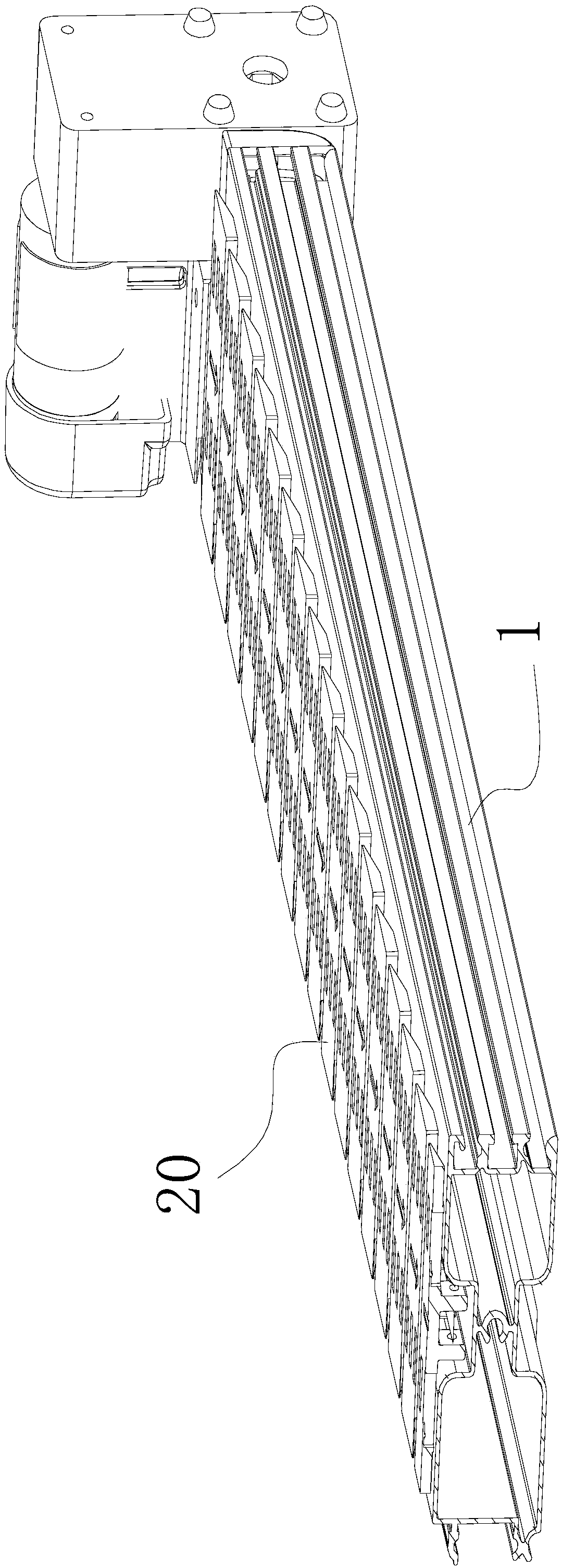

[0023] The load pallet is composed of a power component, a support component and a load component. The power assembly and the load assembly are installed on the support assembly.

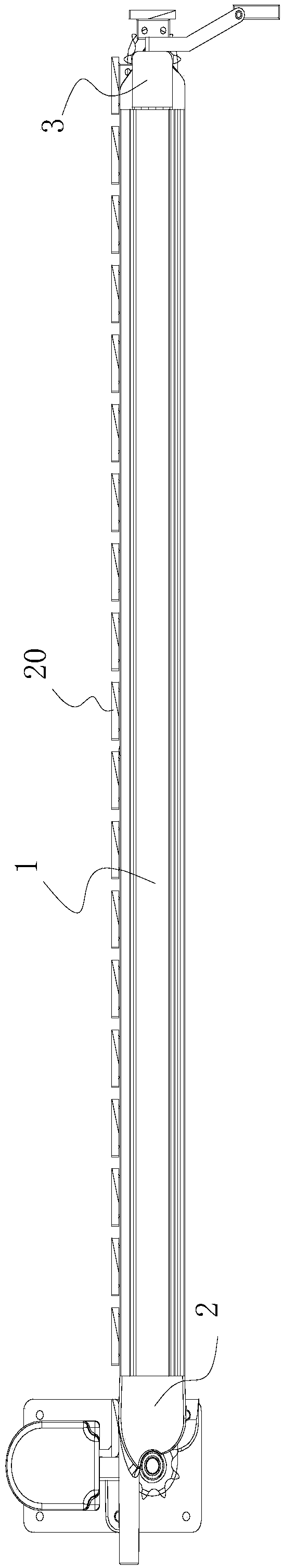

[0024] Such as figure 1 , 2 As shown, the support assembly includes a profile 1 , a driving end support 2 , and a driven end support 3 .

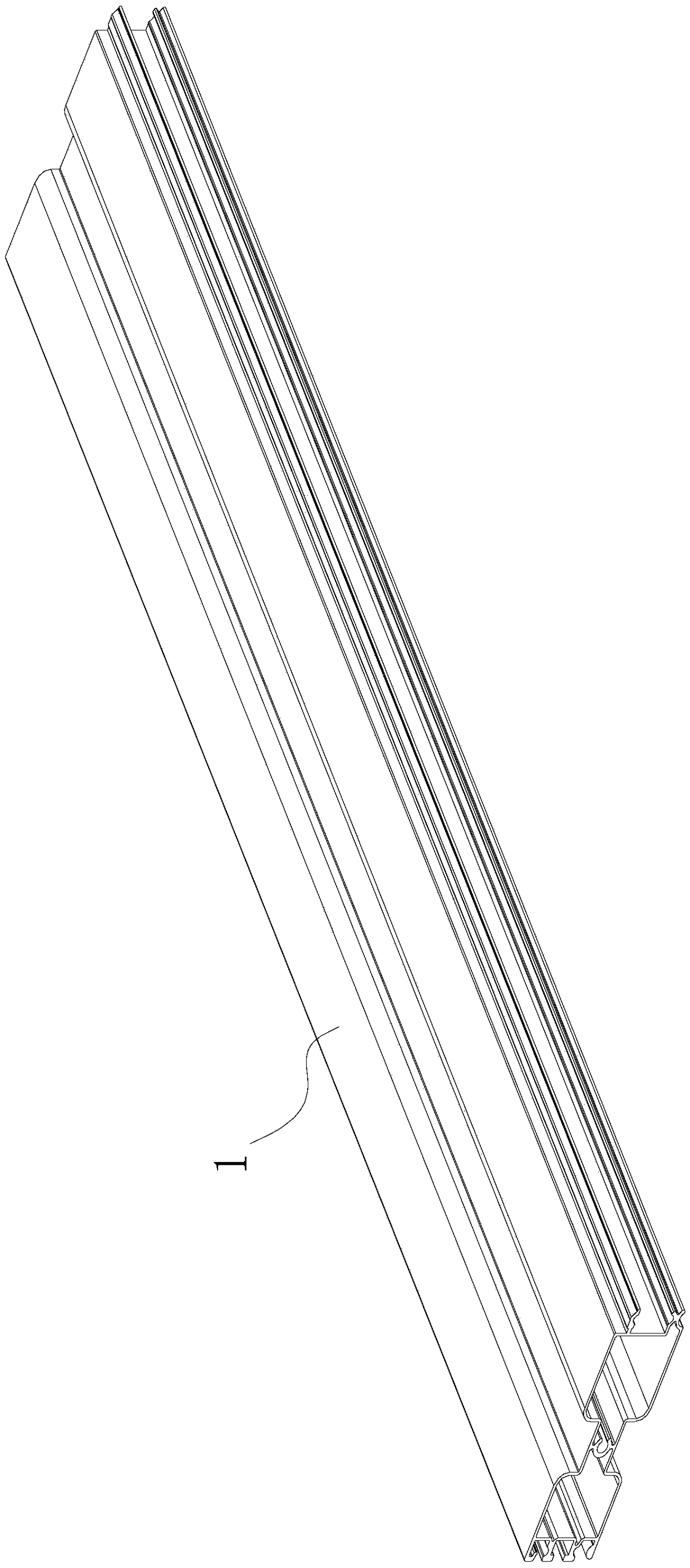

[0025] Such as image 3 , 4 As shown, the profile 1 has a straight and flat structure as a whole, with a cavity inside, except that both ends are open and present as an open structure, and other parts are a dense integral structure. The profile 1 is provided with two chute 4, one of which is located on the side of the profile 1 where one of the surfaces with the largest area and width is located, and the other chute 4 is located at the other surface of the profile 1 with the largest area and width On this side, the chute 4 on both sides is symmetrically distributed. An inlay structure and a receptor structure are respectively provided on the two surfaces of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com