secondary battery

A secondary battery and electrolyte technology, applied to secondary batteries, battery electrodes, circuits, etc., can solve problems affecting battery cycle life and safety, and achieve long cycle life and fast charging capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

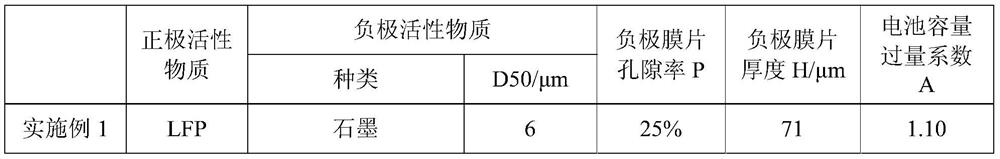

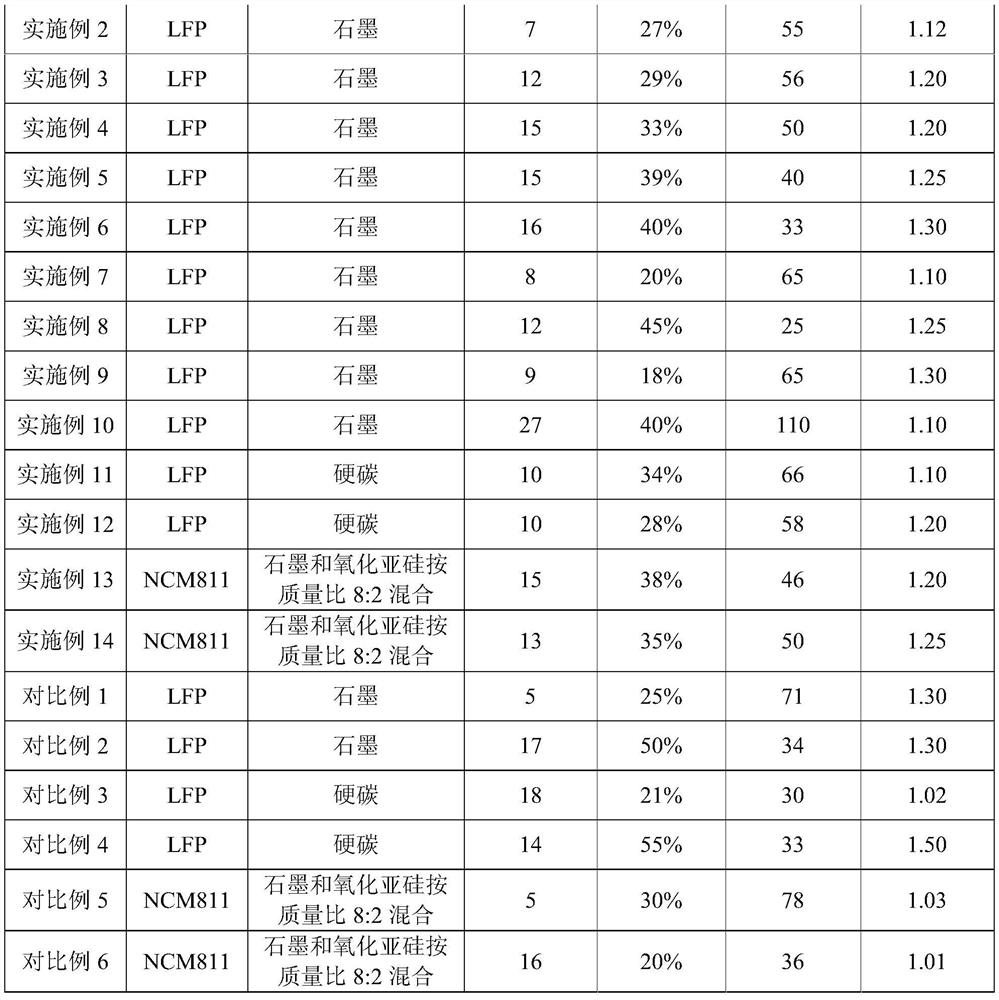

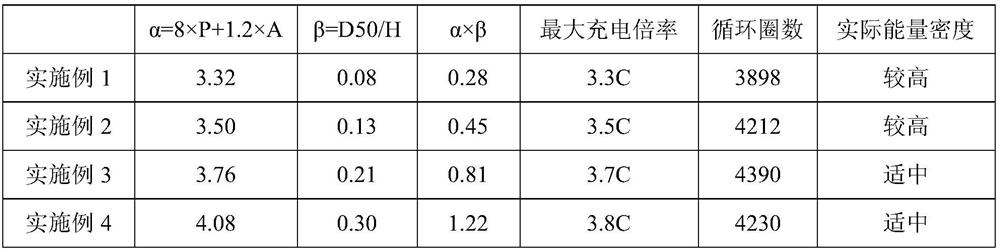

Examples

Embodiment 1

[0038] (1) Preparation of positive pole piece

[0039] Mix the positive electrode active material (see Table 1 for details), conductive agent Super P, and binder polyvinylidene fluoride (PVDF) at a mass ratio of 96:2:2, add solvent N-methylpyrrolidone (NMP), and vacuum Stir under the action of a mixer until the system is uniform to obtain the positive electrode slurry; evenly coat the positive electrode slurry on the aluminum foil of the positive electrode current collector, dry at room temperature, transfer to an oven to continue drying, and then cold press and cut to obtain the positive electrode sheet .

[0040] (2) Preparation of negative pole piece

[0041] After mixing the negative electrode active material (see Table 1 for details), conductive agent Super P, thickener sodium carboxymethylcellulose (CMC), and binder styrene-butadiene rubber (SBR) in a mass ratio of 96.4:1:1.2:1.4 , add the solvent deionized water, stir under the action of a vacuum mixer until the syste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com