A kind of lithium manganese phosphate/lithium vanadium phosphate/carbon composite cathode material and preparation method thereof

A composite cathode material, lithium vanadium fluorophosphate technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of poor cycle performance, poor rate performance of lithium manganese phosphate, etc., to improve ionic conductivity, easy to uniform Dispersion, good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

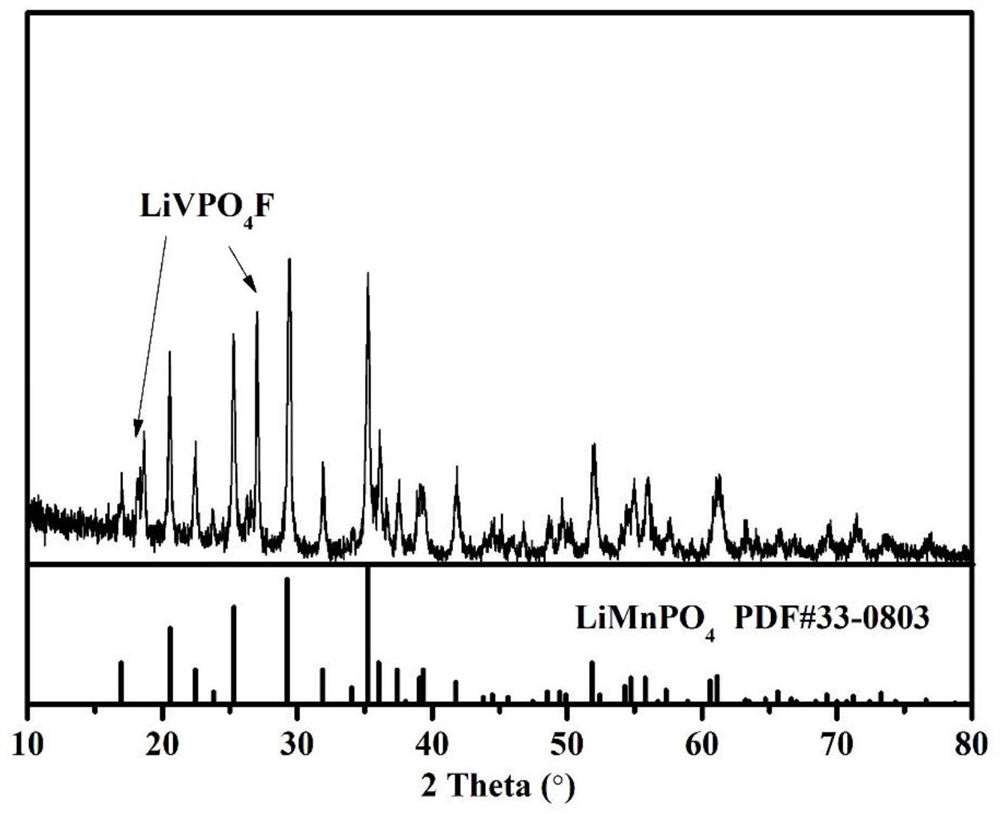

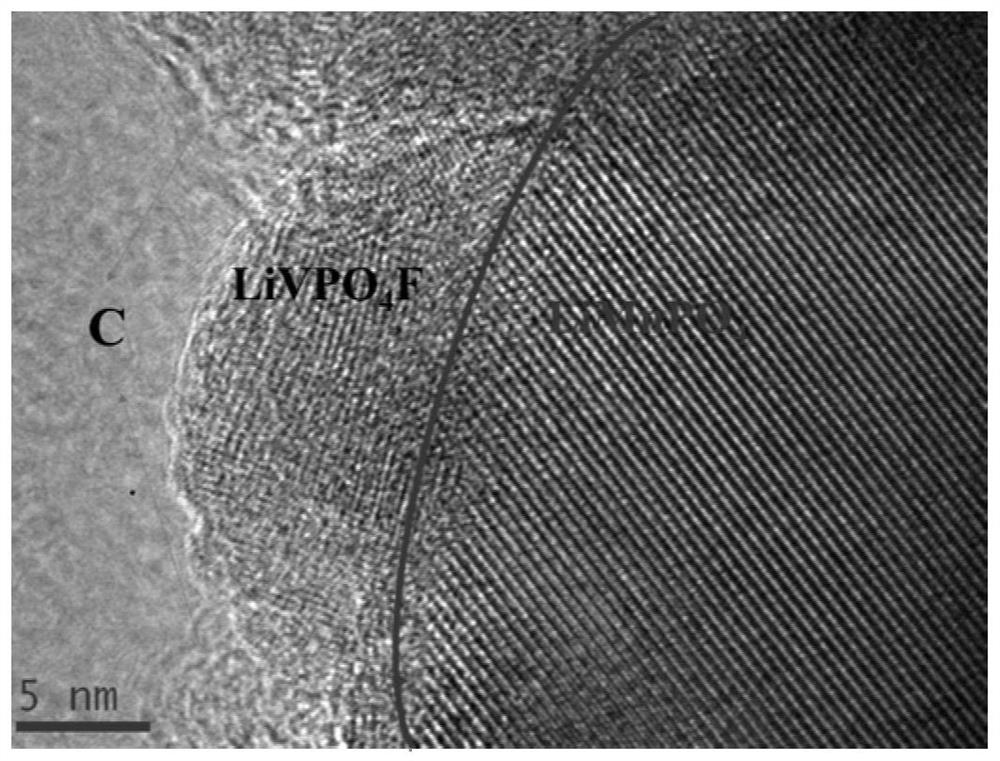

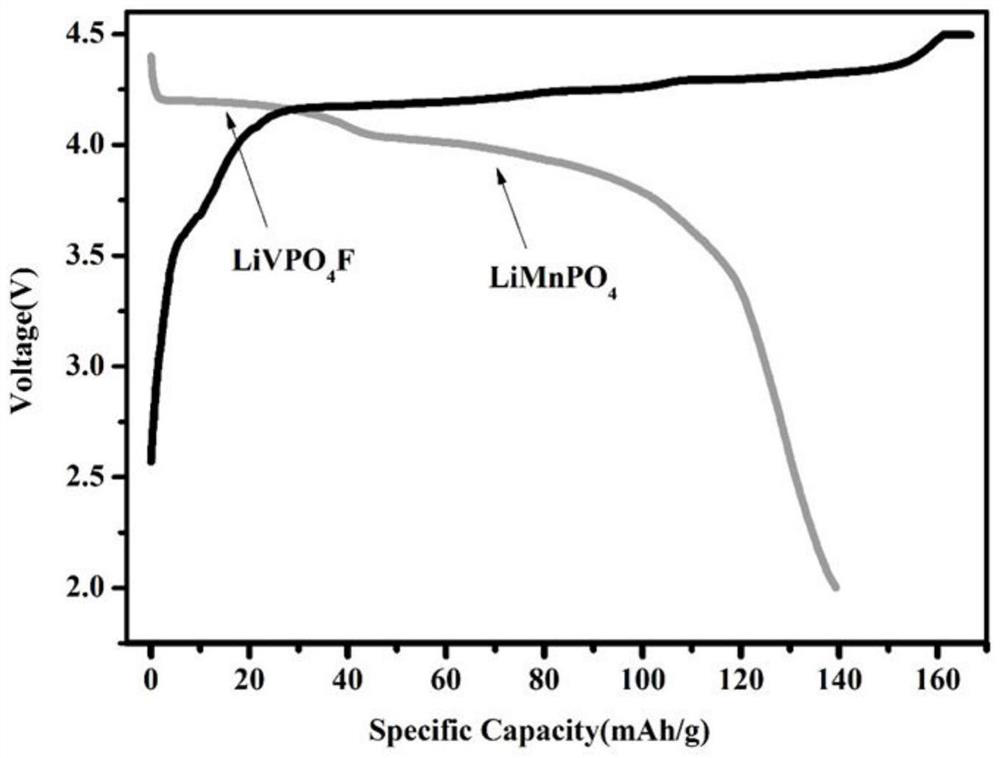

Embodiment 1

[0059] First, weigh 1mmol of vanadium acetylacetonate and dissolve it in 4ml of ethanol, then add 2mmol of H 3 PO 4 and 1.2mmol LiF, sonicated for 1h, and transferred into 4mmol of LiMnPO with an average particle size of 60nm after being fully dissolved and dispersed. 4 In the ethylene glycol solvent system, after ball milling for 3h, the obtained mixed slurry is moved into a round-bottomed flask with a reflux device, and an appropriate amount of ethylene glycol is added as a dispersant and a reflux medium to control the solid content (LiMnPO 4 content) is 30%. After ultrasonic treatment for 30 min, the reaction was strengthened for 12 h at a stirring speed of 300 r / min in a boiling state. The resulting product was washed three times with water and alcohol, and then separated by high-speed centrifugation to obtain a gray-green product, namely LiMnPO 4 / LiVPO 4 Fcomposites. Then the gray-green product was ground and mixed with 15%wt polyvinyl alcohol, placed in an atmosphe...

Embodiment 2

[0062] First weigh 1mmol of vanadium trichloride and dissolve it in 5ml of isopropanol, then add 1.5mmol of H 3 PO 4 , 1.5mmol LiCl and 1.5mmol NH 4 F; Ultrasonic treatment for 1h, after it was fully dissolved and dispersed, it was transferred into LiMnPO with a particle size of 4mmol and a particle size of 80nm 4 In the diethylene glycol solvent system, the mixed slurry obtained after ball milling for 2 hours was transferred to a round bottom flask with a reflux device, and an appropriate amount of ethylene glycol was added as a dispersant and reflux medium to control the solid content of the mixed slurry to 40%. After ultrasonic treatment for 30 min, the reaction was strengthened for 15 h at a stirring speed of 300 r / min in a boiling state. The resulting product was washed three times with water and alcohol, and then separated by high-speed centrifugation to obtain a gray-green product, namely LiMnPO 4 / LiVPO 4 Fcomposites. Then the gray-green product was ground and mix...

Embodiment 3

[0066] First weigh 1.5mmol of vanadium acetylacetonate (about 538.5mg) and dissolve it in 4.5ml of ethanol and 1.5ml of acetone, add 3mmol of H 3 PO 4 and 2mmol LiF; ultrasonic treatment for 2h, after it was fully dissolved and dispersed, it was transferred into 3.5mmol LiMnPO with a particle size of 50 4 In the triethylene glycol solvent system, after ball milling for 4 hours, move the obtained precursor slurry into a round-bottomed flask with a reflux device, and add an appropriate amount of triethylene glycol as a dispersant and a reflux medium, so that the solid content in the mixed slurry is 25 %. After ultrasonic treatment for 30 min, the reaction was strengthened for 18 h at a stirring speed of 300 r / min in a boiling state. The resulting product was washed three times with water and alcohol, and then separated by high-speed centrifugation to obtain a gray-green product, namely LiMnPO 4 / LiVPO 4 Fcomposites. Then the gray-green product was ground and mixed with 15% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com