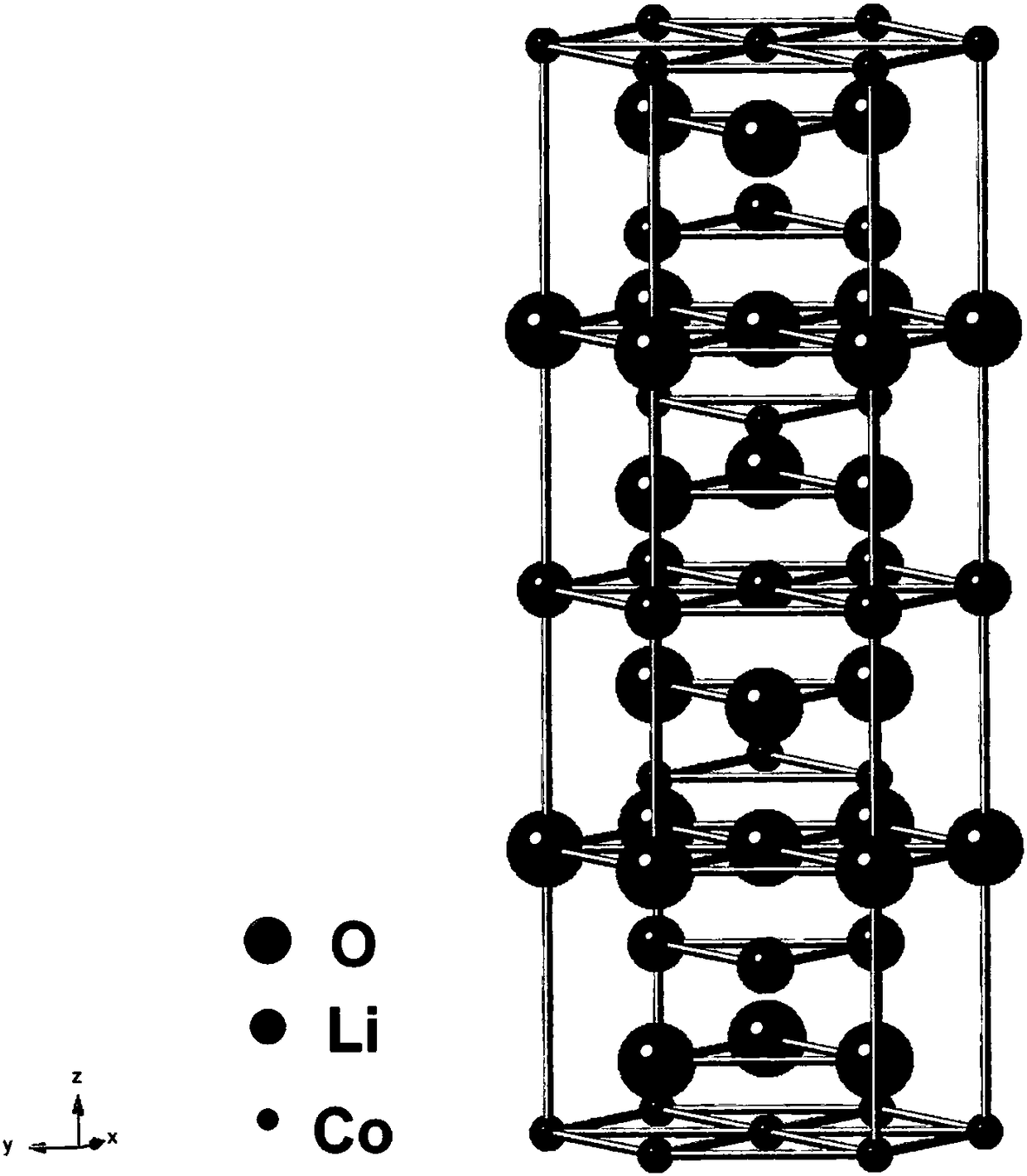

Lithium cobaltate positive electrode material and preparation method thereof, and lithium ion secondary battery

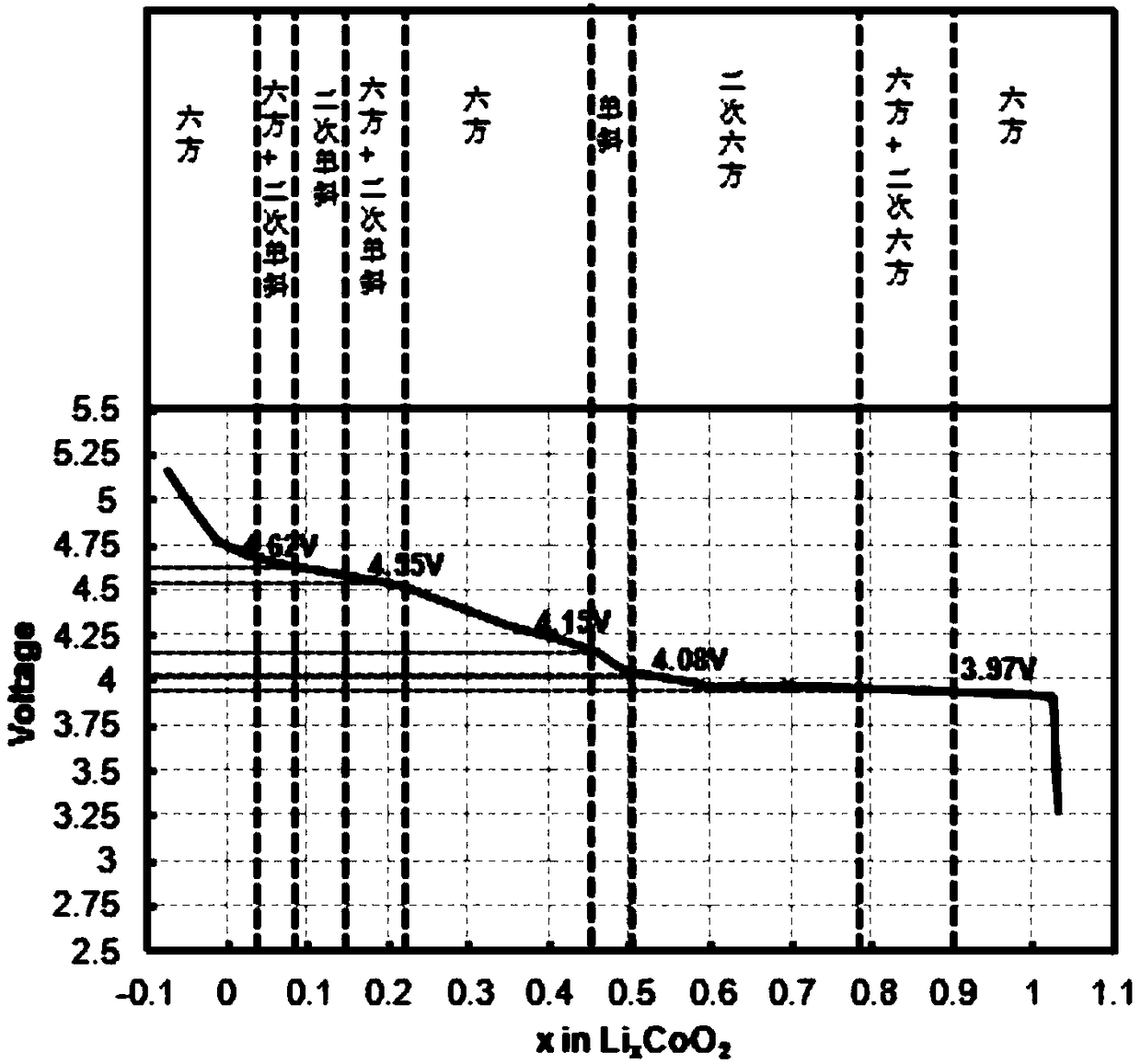

A positive electrode material, lithium cobalt oxide technology, applied in the field of materials, can solve the problems of limited release, stable structure, and inability to buffer well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

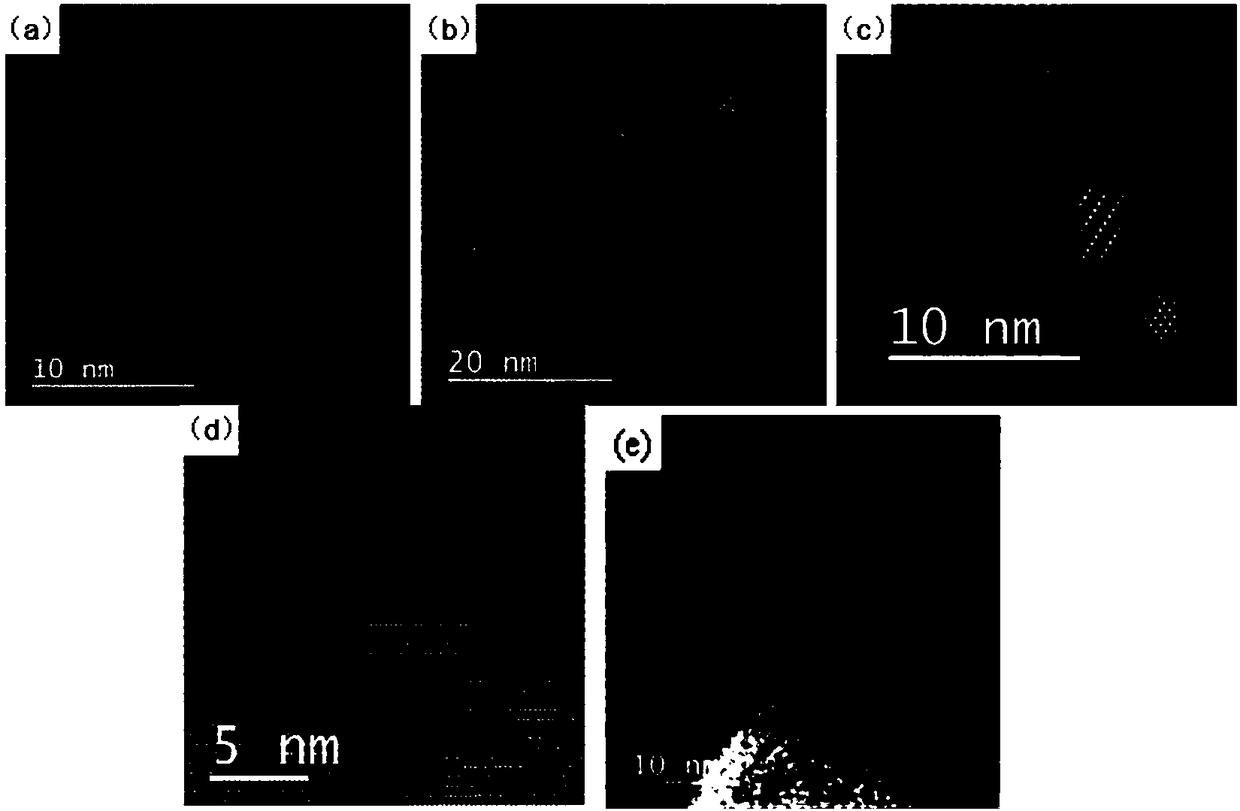

Image

Examples

preparation example Construction

[0066] In another embodiment of the present invention, a method for preparing a structurally stable high-voltage lithium cobalt oxide cathode material co-modified by doping and surface coating is also provided, the method comprising:

[0067] Step (1): Using the controlled crystallization method, according to the molar ratio, take an appropriate amount of cobalt source and a compound containing the invariant element Ma, prepare an aqueous solution containing Co ions and the invariant element Ma ion, and mix it with the complexing agent solution and the precipitating agent solution Make it react to crystallize, stir at the same time, and control the pH value of the reaction system to be 6-12, perform centrifugal filtration after crystallization, obtain the carbonate or hydroxide of cobalt doped with the invariant element Ma;

[0068] Step (2): According to the molar ratio, take an appropriate amount of the compound containing the variable valence element Mb and the carbonate or ...

Embodiment 1

[0110] A structurally stable high-voltage lithium cobaltate cathode material, which is doped with Al and Ni by lithium cobaltate and coated with LiCo 0.5 Ni 0.5 o 2 Formed, its molecular formula is 0.005LiCo 0.5 Ni 0.5 o 2 0.995LiCo 0.996 Al 0.003 Ni 0.001 o 2 , its preparation method comprises the following steps:

[0111] (1) Dissolve CoSO with deionized water 4 、Al 2 (SO 4 ) 3 , configured as a mixed salt solution with a molar ratio of Co:Al=99.6:0.3, and the Co in the mixed salt solution 2+ The concentration of the solution is 1.25mol / L; select strong ammonia water and distilled water to configure a complexing agent solution in a volume ratio of 1:10; select 1.2mol / L sodium carbonate solution as a precipitant solution; inject 1 / 3 of its solvent into the reaction kettle Precipitant solution, under strong stirring and inert gas protection, adopt the method of co-current control flow to continue to inject the above-mentioned mixed salt solution, complexing agent ...

Embodiment 2

[0117] A structurally stable high-voltage lithium cobaltate cathode material, made of lithium cobaltate doped with Al and Cr, and coated with LiNiPO 4 Formed, its molecular formula is 0.005LiNiPO 4 0.995 Li 1.03 co 0.995 Al 0.004 Cr 0.001 o 2 , its preparation method comprises the following steps:

[0118] (1) Dissolve CoSO with deionized water 4 、Al 2 (SO 4 ) 3 , configured as a mixed salt solution with a molar ratio of Co:Al=99.5:0.4, and the Co in the mixed salt solution 2+ The concentration of the solution is 1.25mol / L; select strong ammonia water and distilled water to configure a complexing agent solution in a volume ratio of 1:10; select 1.2mol / L sodium carbonate solution as a precipitant solution; inject 1 / 3 of its solvent into the reaction kettle Precipitant solution, under strong stirring and inert gas protection, adopt the method of co-current control flow to continue to inject the above-mentioned mixed salt solution, complexing agent solution and precipit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com