Energy-saving gas water heater

A technology of gas water heaters and air holes, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of energy waste, heat loss, coils being corroded and perforated by condensed water, etc., to prolong the heat exchange time, Reduce heat loss and improve thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

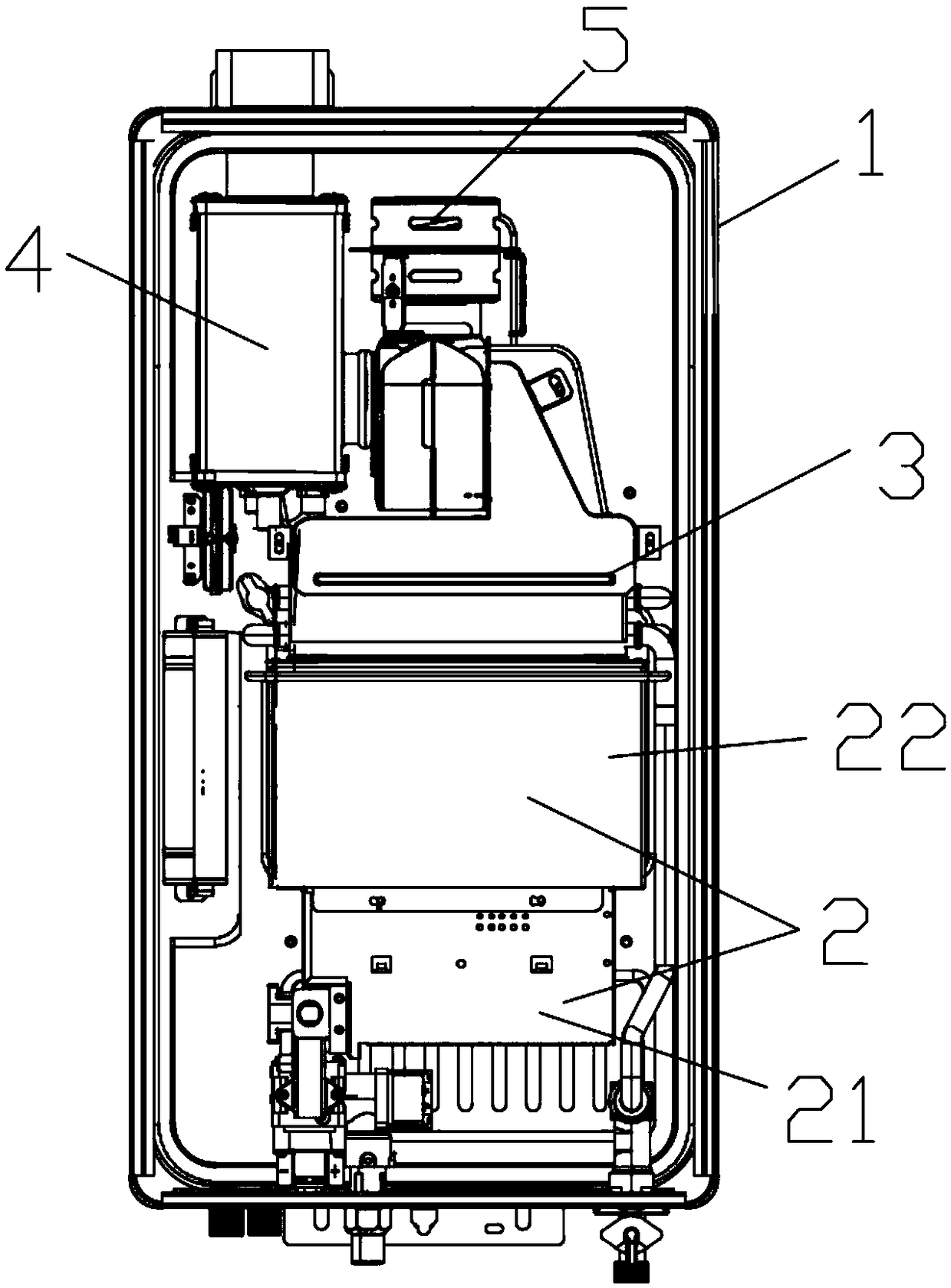

[0028] see attached Figure 1-8 , an energy-saving gas water heater, comprising:

[0029] shell 1;

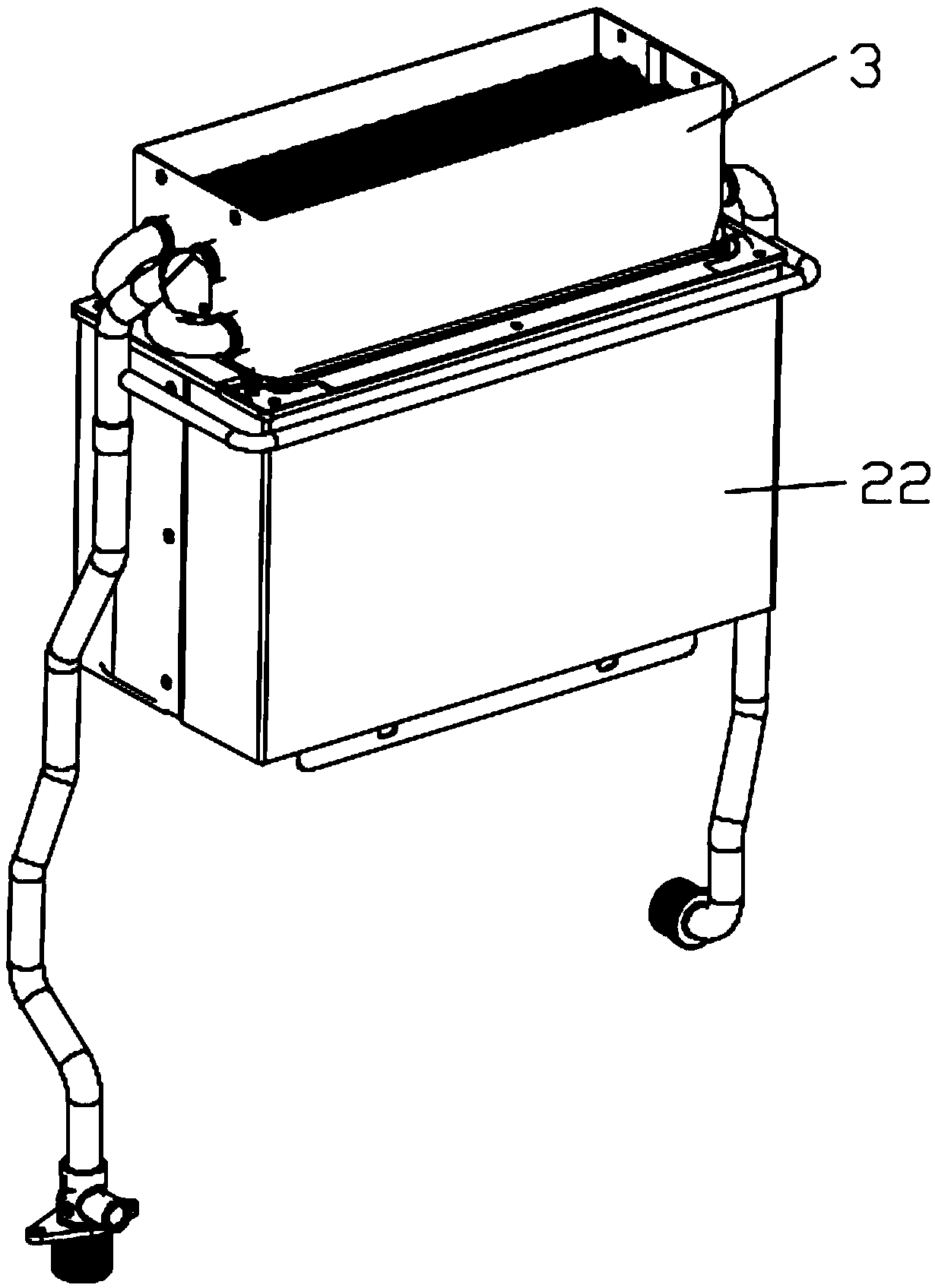

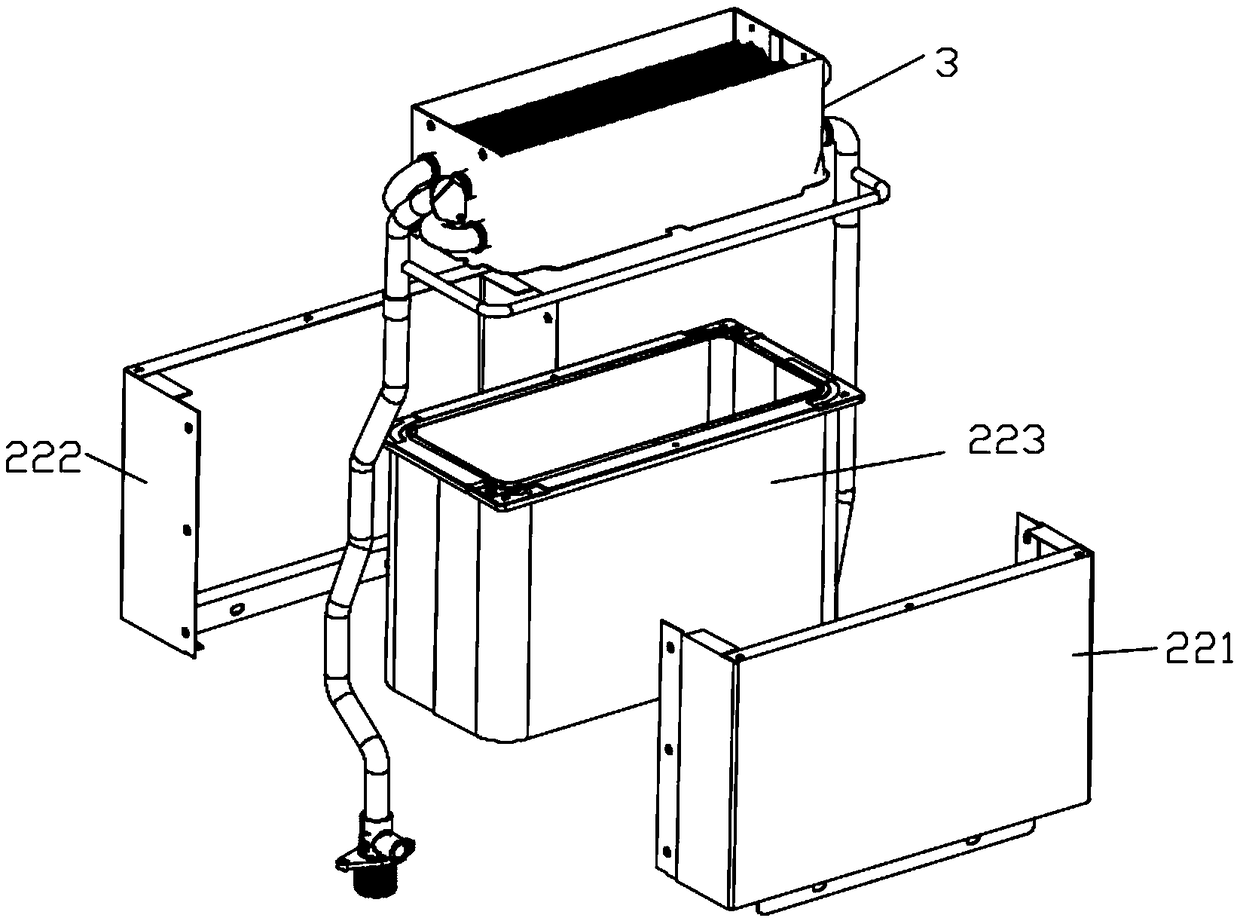

[0030] Combustion device 2, the combustion device 2 is arranged in the casing 1, the combustion device 2 is provided with a fire row 21 and a combustion chamber 22, the combustion chamber 22 is arranged above the fire row 21, and the combustion chamber 22 is The peripheral wall is provided with a fireproof and thermal insulation layer 223 to prevent the heat in the combustion chamber 22 from radiating to the outside, reducing the heat loss and improving the thermal efficiency at the same time. The problem of perforation and water leakage due to corrosion of the cavity coil greatly reduces the occurrence of after-sales and saves costs;

[0031] The heat exchange device 3 is arranged above the combustion chamber 22, and a plurality of heat exchange fin units 31 are arranged on the heat exchange device 3, and the heat exchange fin units 31 are respectively provided with a plural...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap