Train current collection mechanism

A technology for trains and electricity collection, applied in current collectors, power collectors, electric vehicles, etc., can solve problems such as poor power performance matching, affecting contact collection performance, and restricting rigid systems, etc., to achieve good contact collection The effect of electrical performance, superior performance and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

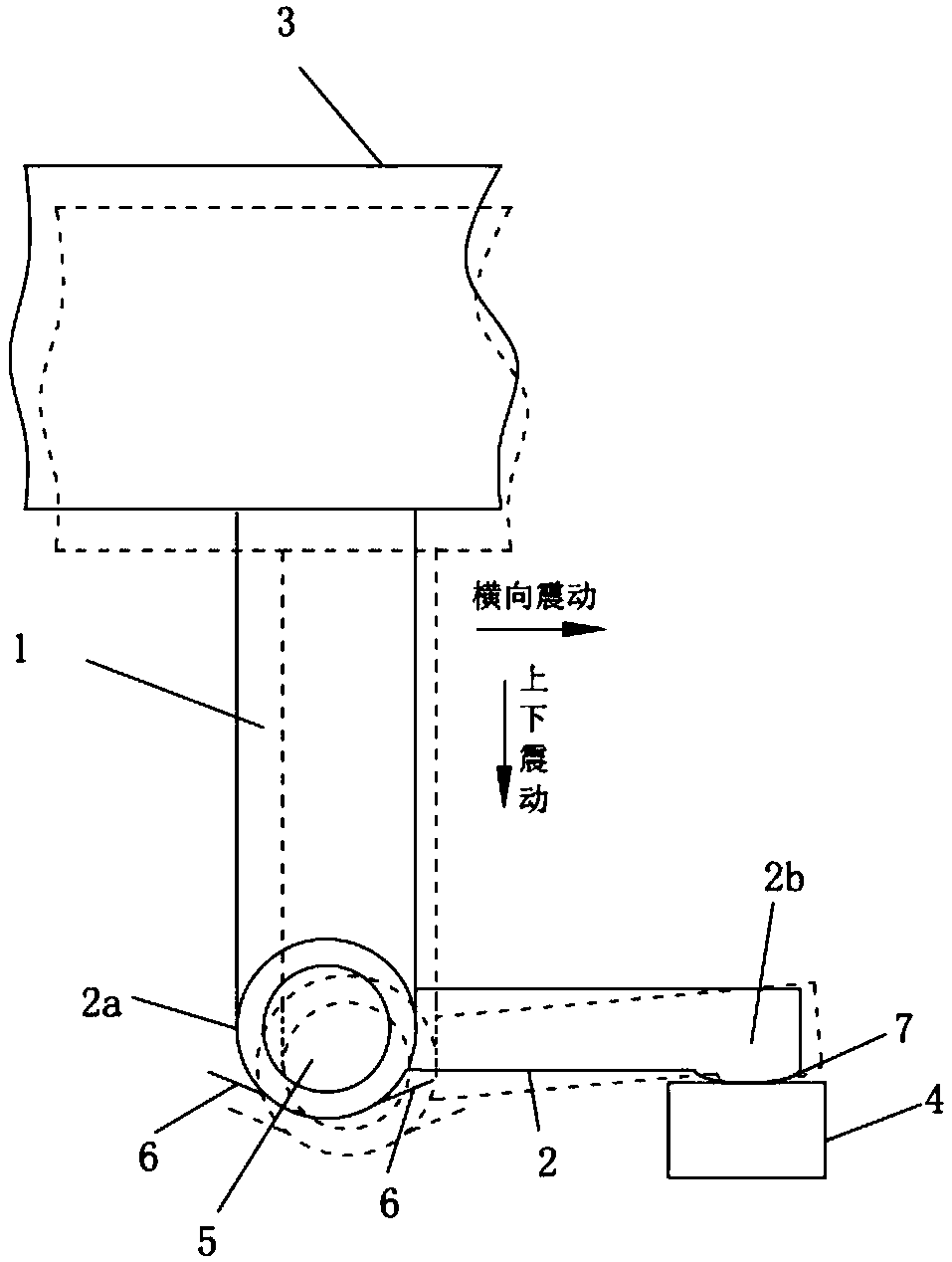

[0027] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides a train power collection mechanism, including a boot 1 and a power collection shoe 2, the top of the boot 1 is fixedly connected to the end of the longitudinal beam of the train bogie 3, and the bottom of the boot 1 The end is hinged with the connection end 2a of the collector shoe 2 through a fastener 5; the bottom of the free end 2b of the collector shoe 2 is provided with a contact portion 7 and contacts with the top of the power supply rail 4; the connection end of the collector shoe 2 2a is connected to the cable (not shown) leading to the traction drive system of the train; the bottom end of the boot 1 is provided with a limiting piece 6 for limiting the sagging angle and range of the collector shoe 2 . In the embodiment of the present invention, the boot 1 is an insulator, the collector shoe 2 is a conductor, the power supply rail 4 is arranged inside the boot 1, and the fa...

Embodiment 2

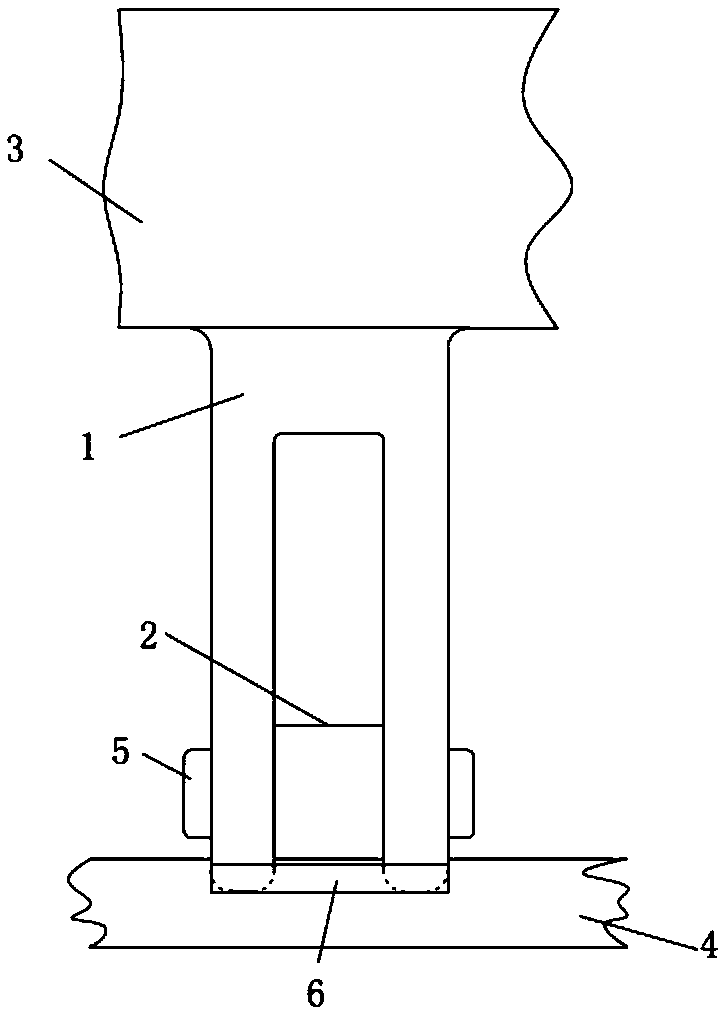

[0031] Such as Figure 4 As shown, the embodiment of the present invention provides a train power collection mechanism, including a boot 1 and a power collection shoe 2, the top of the boot 1 is fixedly connected to the end of the longitudinal beam of the train bogie 3, and the bottom of the boot 1 The end is hingedly connected to the connecting end 2a of the collector shoe 2 through a fastener 5; the bottom of the free end 2b of the collector shoe 2 is downwards to the contact portion 7 and contacts the upper surface of the power supply rail 4; the collector shoe 2. The connecting end 2a is connected to the cable (not shown) leading to the traction drive system of the train; the bottom end of the boot 1 is provided with a limiting piece 6 for limiting the sagging angle and range of the collector shoe 2. In the embodiment of the present invention, the boot 1 is an insulator, the collector shoe 2 is a conductor, the power supply rail 4 is arranged inside the boot 1, and the fas...

Embodiment 3

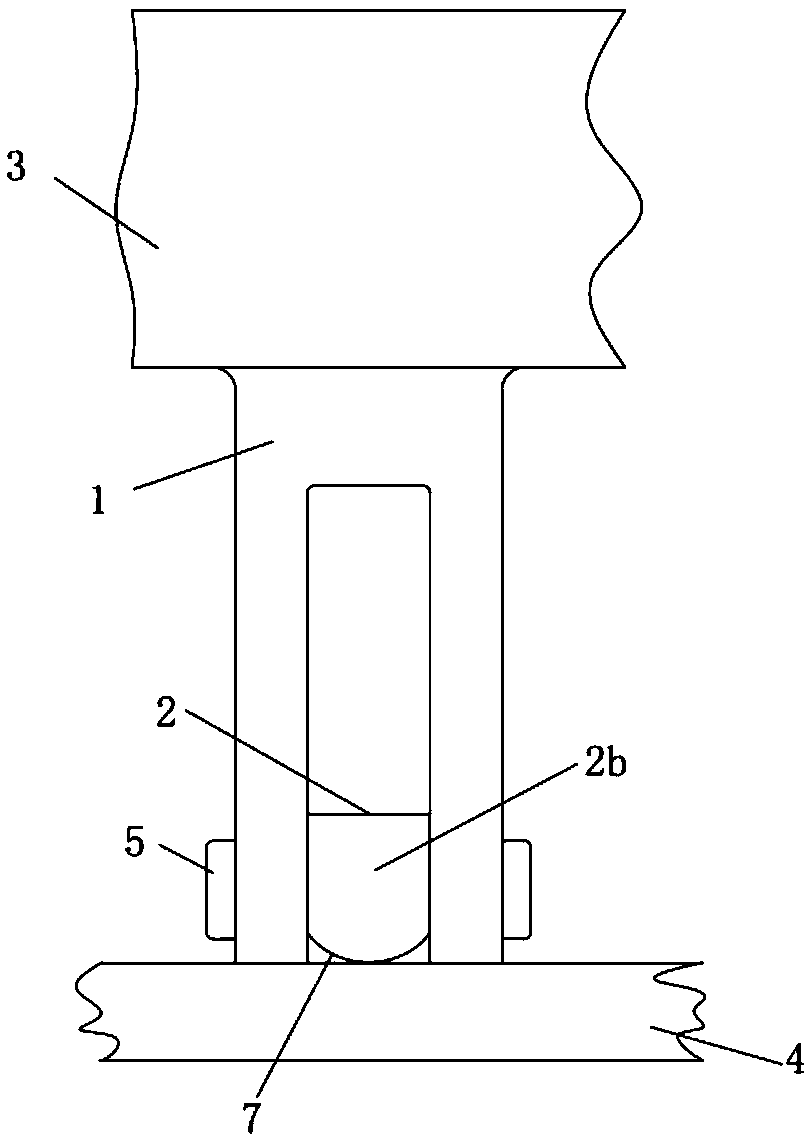

[0035] Combined with the above-mentioned second embodiment Figure 4 and the embodiment of the present invention Figure 6As shown, the embodiment of the present invention provides a train power collection mechanism, including a boot 1 and a power collection shoe 2, the top of the boot 1 is fixedly connected to the end of the longitudinal beam of the train bogie 3, and the bottom of the boot 1 The end is hingedly connected to the connecting end 2a of the collector shoe 2 through a fastener 5; the bottom of the free end 2b of the collector shoe 2 is downwards to the contact portion 7 and contacts the top of the power supply rail 4; the collector shoe 2. The connecting end 2a is connected to the cable (not shown) leading to the traction drive system of the train; the bottom end of the boot 1 is provided with a limiting piece 6 for limiting the sagging angle and range of the collector shoe 2. In the embodiment of the present invention, the boot 1 is an insulator, the collector s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap